6

PRODUCT MANUAL

1800 358 101

sales.au@westlab.com

www.westlab.com.au

+64 9 553 3677

sales.nz@westlab.com

www.westlab.co.nz

646 568 5391

sales.us@westlab.com

www.westlab.com

1 877 822 1455

sales.ca@westlab.com

www.westlab.com

Australia New Zealand United StatesCanada

3. Safety Precautions

The Bottle Top Dispensers may sometimes be used with hazardous materials,

operations, and equipment. It is beyond the scope of this manual to address all the

potential risks associated with its use in such applications. It is the responsibility of

the user of these dispensers to consult and establish appropriate safety and health

practice and determine

the applicability of regulatory limitations prior to use.

Please comply with the following safety instructions:

• Follow all general directions for hazard prevention and safety instructions e.g.,

wear protective clothing, eye protection and gloves.

• Observe all specications provided by the reagent manufacturers.

• When dispensing inammable media, avoid the build up of static charge. Do not

dispense into plastic vessels.

• Only use the unit for dispensing liquids with strict regard to the dened limitations

of use and operating limitations.

• Always use the instrument in a way that neither the user nor any other person is

endangered. When dispensing, the discharge tube must always point away from

the user or any other person. Avoid splashes. Only dispense into suitable vessels.

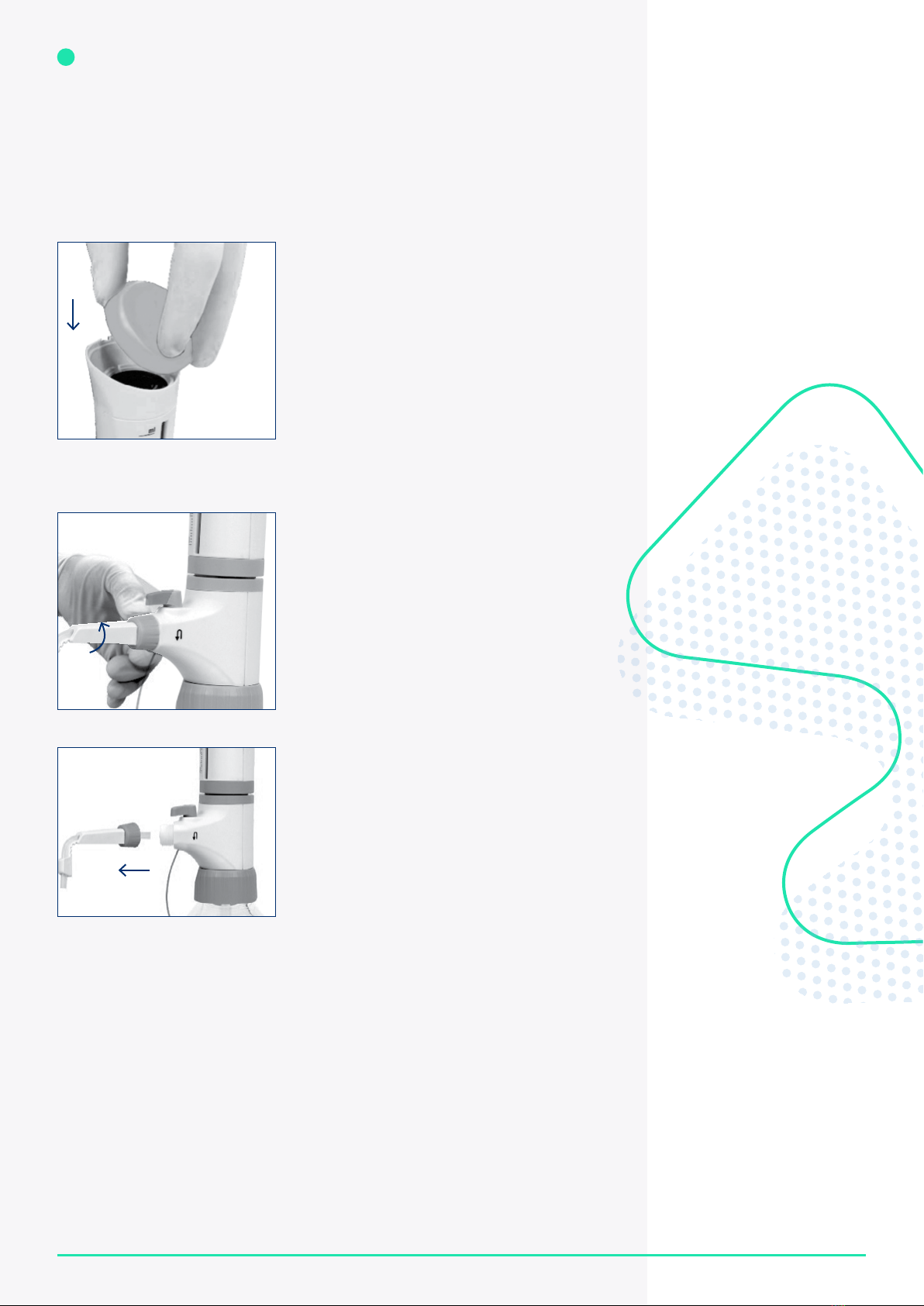

• Never press down on the piston when the discharge tube closure is attached.

• Never remove the discharge tube while the dispensing cylinder is lled.

• Never carry the mounted unit by the cylinder sleeve or the valve block. The breakage

or loosening of the cylinder may lead to personal injury from chemical exposure.

• Never use force on the dispensers. Use smooth, gentle movements to operate the

piston upwards and downwards. Only use the original accessories and spare parts.

• Do not wipe the unit with a dry cloth.

• Regularly clean the cap of the discharge tube to avoid reagent build up.

• Only use the original accessories and spare parts.

• Do not attempt to make any technical alterations. Do not dismantle the unit any

further than is described in this manual.

• Always check the unit for visual damage before use.

• If there is a sign of a potential malfunction, immediately stop dispensing.

• Store the Bottle Top Dispensers and accessories in a clean, cool, and dry place.

The recommend storage temperature is between -20°C and +50°C [-4°F to +122°F].

• This product cannot be used with hydrouoric acid or any chemical that attacks

glass. A chemical compatibility chart is provided in this manual for detailed

special conditions.

• Calibrations can be performed onsite by end user.