Contents

Contents..........................................................................................................................................................................3

Introduction .....................................................................................................................................................................4

Nordson EFD Product Safety Statement ........................................................................................................................5

Halogenated Hydrocarbon Solvent Hazards ...............................................................................................................6

High Pressure Fluids....................................................................................................................................................6

Qualified Personnel......................................................................................................................................................6

Intended Use ...............................................................................................................................................................7

Regulations and Approvals..........................................................................................................................................7

Personal Safety............................................................................................................................................................7

Fire Safety....................................................................................................................................................................8

Preventive Maintenance ..............................................................................................................................................8

Important Disposable Component Safety Information ................................................................................................9

Action in the Event of a Malfunction............................................................................................................................9

Disposal .......................................................................................................................................................................9

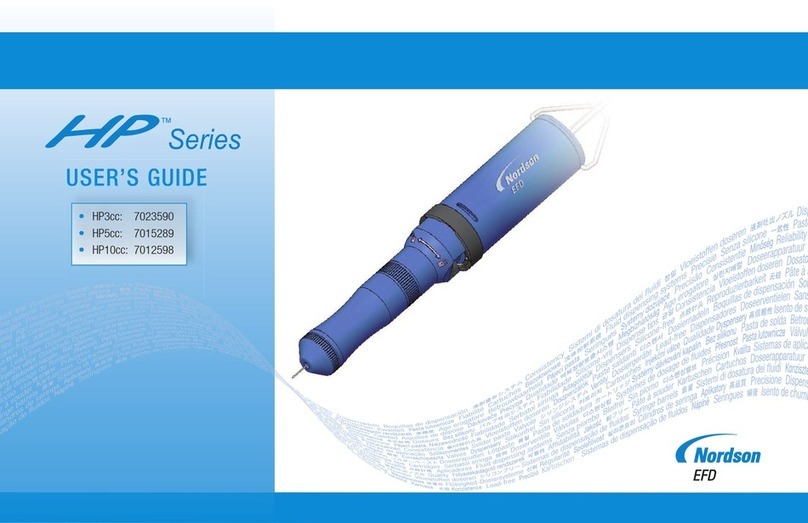

Specifications................................................................................................................................................................10

First Steps .....................................................................................................................................................................11

Features & Controls: Front Panel ..................................................................................................................................12

Manual / Programmed Dispense Select ....................................................................................................................12

Cycle Start .................................................................................................................................................................12

Program Number .......................................................................................................................................................13

Barrel Select ..............................................................................................................................................................13

Reset..........................................................................................................................................................................13

Home (F1) ..................................................................................................................................................................14

Jog (F2) ......................................................................................................................................................................14

Shot Count / Deposit Volume (F3) .............................................................................................................................15

Reset Shot Count (F4) ...............................................................................................................................................15

Deposit Volume / Forward .........................................................................................................................................16

Pause.........................................................................................................................................................................16

Pullback / Back..........................................................................................................................................................17

Manual Dispense Rate...............................................................................................................................................18

Increase and Decrease ..............................................................................................................................................18

Features & Controls: Back Panel ..................................................................................................................................19

Attaching the Syringe Barrel..........................................................................................................................................20

Attaching the Barrel / Purging the Tip .......................................................................................................................20

Removing the Syringe Barrel .....................................................................................................................................20

Program Function..........................................................................................................................................................21

How to Make a Bead.....................................................................................................................................................22

Modify Function.............................................................................................................................................................23

Operating Tips...............................................................................................................................................................24

Pre-Load Adjustment ....................................................................................................................................................25

Syringe Barrel Filling......................................................................................................................................................26

Input / Output Connection ............................................................................................................................................27

Voltage Initiate Circuit................................................................................................................................................27

Mechanical Contact Initiate .......................................................................................................................................27

End-of-Cycle Feedback Circuit .................................................................................................................................27

Pin Function...............................................................................................................................................................27

Part Numbers ................................................................................................................................................................28

Accessories ...................................................................................................................................................................28

Components..................................................................................................................................................................29

Replacement Parts........................................................................................................................................................29

Troubleshooting ............................................................................................................................................................30

Ultimus IV Series Dispensers

3

www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.