8

AUTO DETECT

This product includes the exclusive “Auto-detect” feature for the charging of batteries. With this

new technology, the power converter will evaluate the charging cycle of a battery, determine the

type of battery being used, and then choose the appropriate charging program(prole) to

provide for the best performance and maintenance of that battery.

Because of the differences of Lead Acid, AGM and Lithium type batteries, a system that provides

a charge to the battery or batteries must be able to accommodate the different charging

requirements. With the use of the “Auto-detect” product, the charging requirement is able to be

“detected” and is then automatically set for the type of battery being used. For standard Lead

Acid and AGM batteries, WFCO power converters still use the Three-Stage Smart Charging to

effectively maximize battery life by monitoring through the different phases of the charge cycle.

On the other hand, Lithium batteries will prefer the use of only two stages when charging, and

therefore the power converter will charge using the WFCO Two-Stage Smart Charging system.

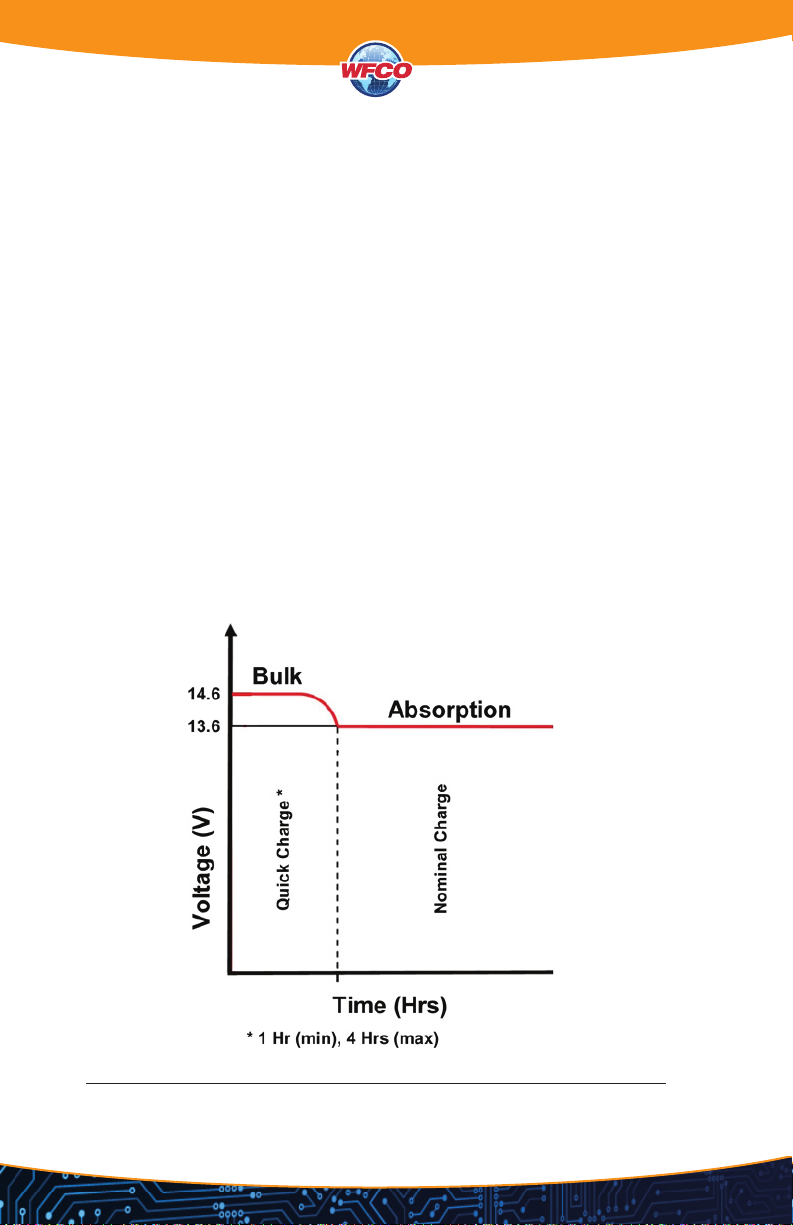

LEAD ACID & AGM THREE-STAGE SMART CHARGING

The three-stage “smart” charger continuously measures the battery voltage output and regulates

the amount of charge using three modes of operation: Absorption, Bulk, and Float.

3-STAGE CHARGING

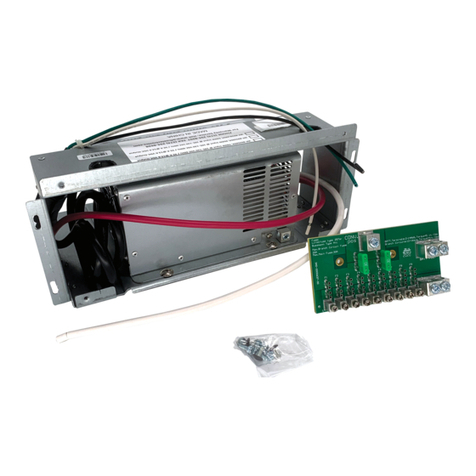

WFCO converters of every style have become the favored brand for power conversion and

electric distribution in the RV industry. They provide RV owners wth an efcient and cost-effective

method to use an AC power source and provide power to DC components inside the RV, while

charging accessory batteries at the same time.

SMART ENGINEERING: THREE STAGE CHARGING IS BETTER

WFCO’s automatic three-stage converters handle every charging need for the RV while extending

the battery’s life. Well-maintained batteries should never need more than two-stage (Normal and

Trickle) charging. Our third stage (Bulk) is provided for the rare times a battery needs extra power

for charging.

RVs are frequently sold with at least one 12 VDC accessory battery installed. This battery is

normally a deep-cycle battery that could sustain a slower drain of power. RV owners nd this

useful when powering loads such as lights, radios, and refrigerators without being

connected to AC power or running the motorhome engine. As soon as the RV is connected to

AC power, the converter begins charging the battery as needed, while, at the same time, provid-

ing 12 VDC power to loads such as lights, radios, and refrigerators.

When the RV is connected to AC power, users frequently use the lights, refrigerators, fans, and

other electronics as they would in their home. RV users also expect the battery to be fully charged

when they want to disconnect from power and move the RV, or when they are dry camping and

turn off their generator.

OPERATIONAL FEATURES