Contents

Contents..................................................................................................................................................2

1.0 General..............................................................................................................................................3

1.1 Application....................................................................................................................................3

1.2 Warnings ................................................................................................................................3

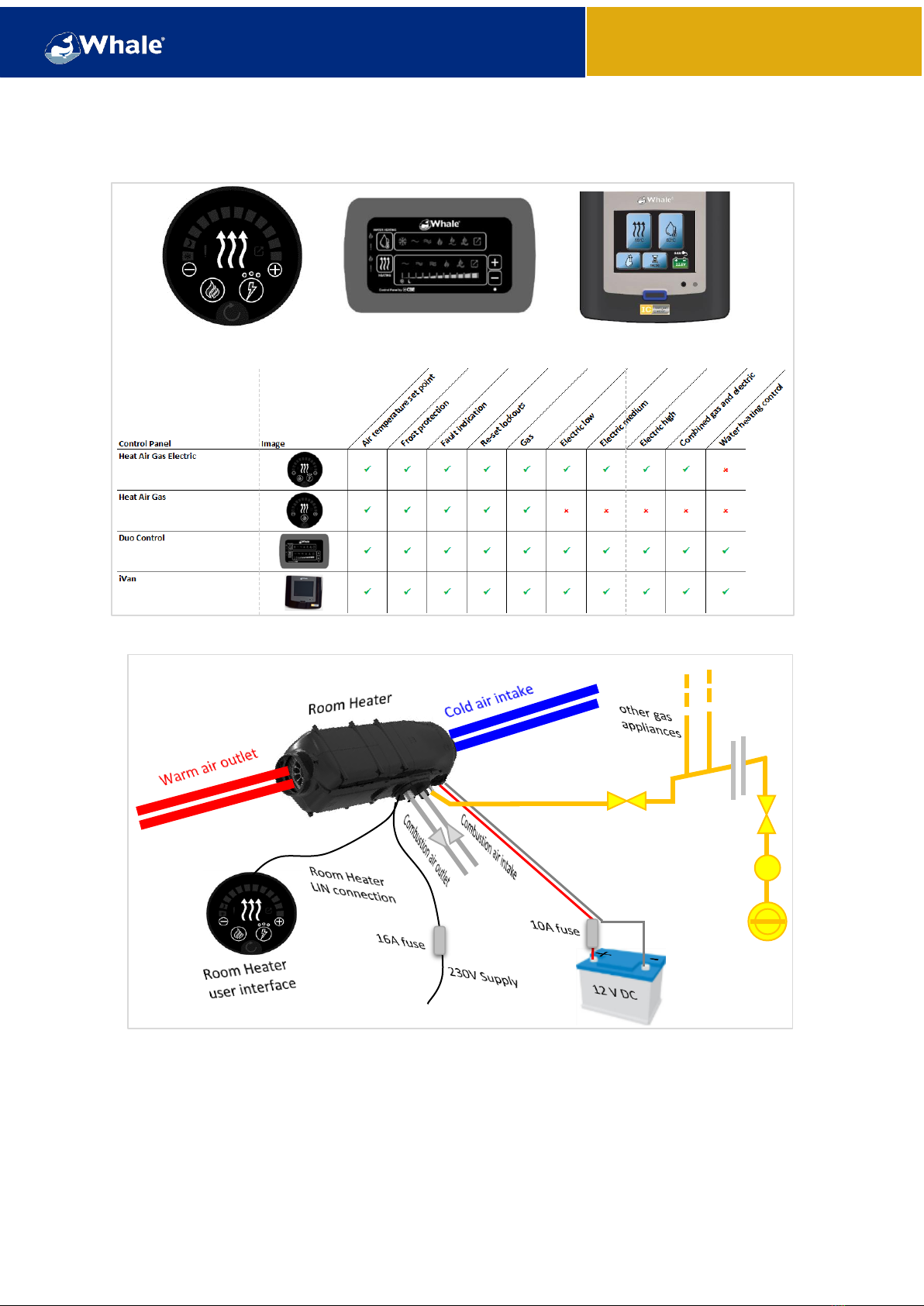

2.1 Product Description ......................................................................................................................5

2.2 Product Operation ........................................................................................................................5

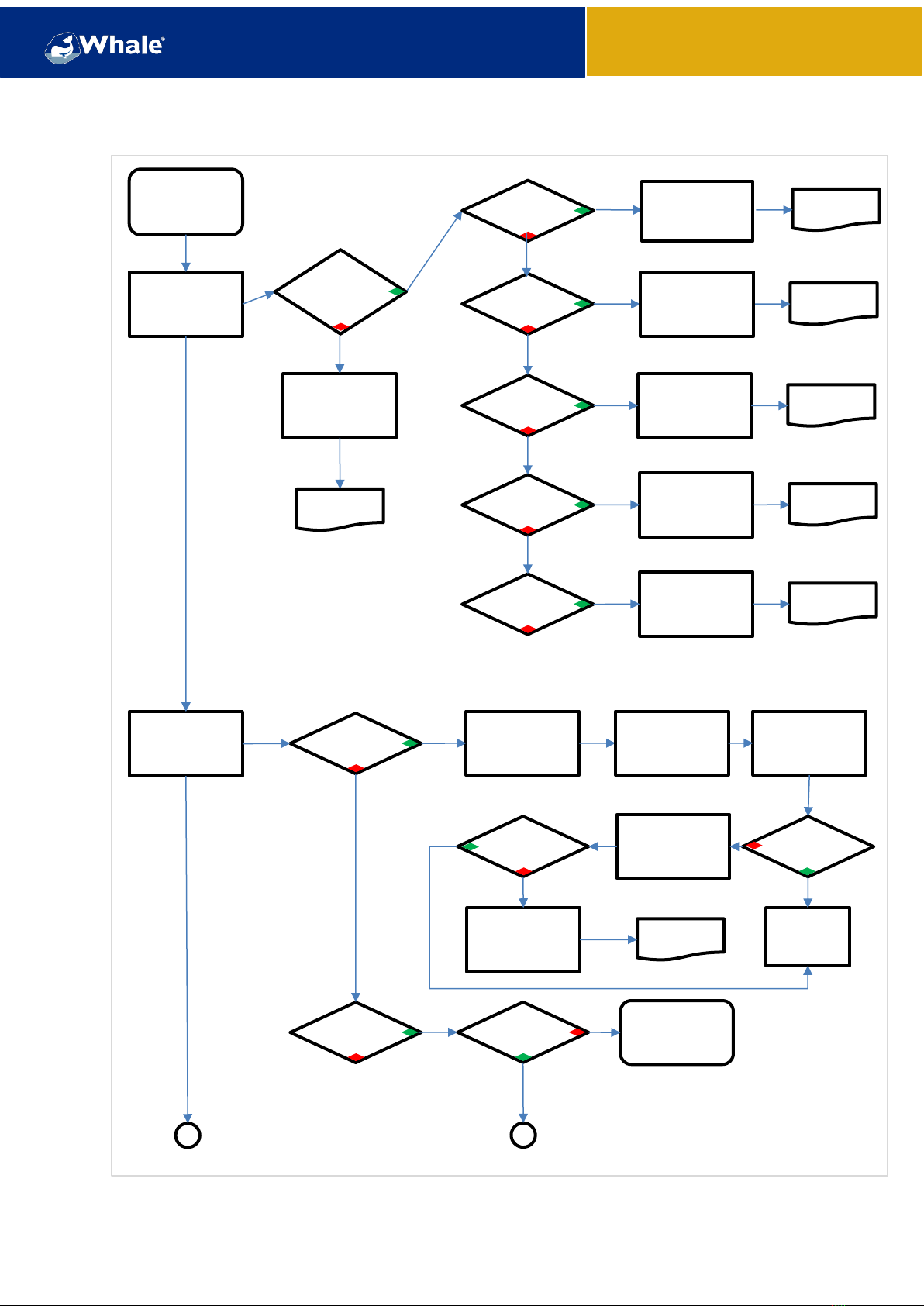

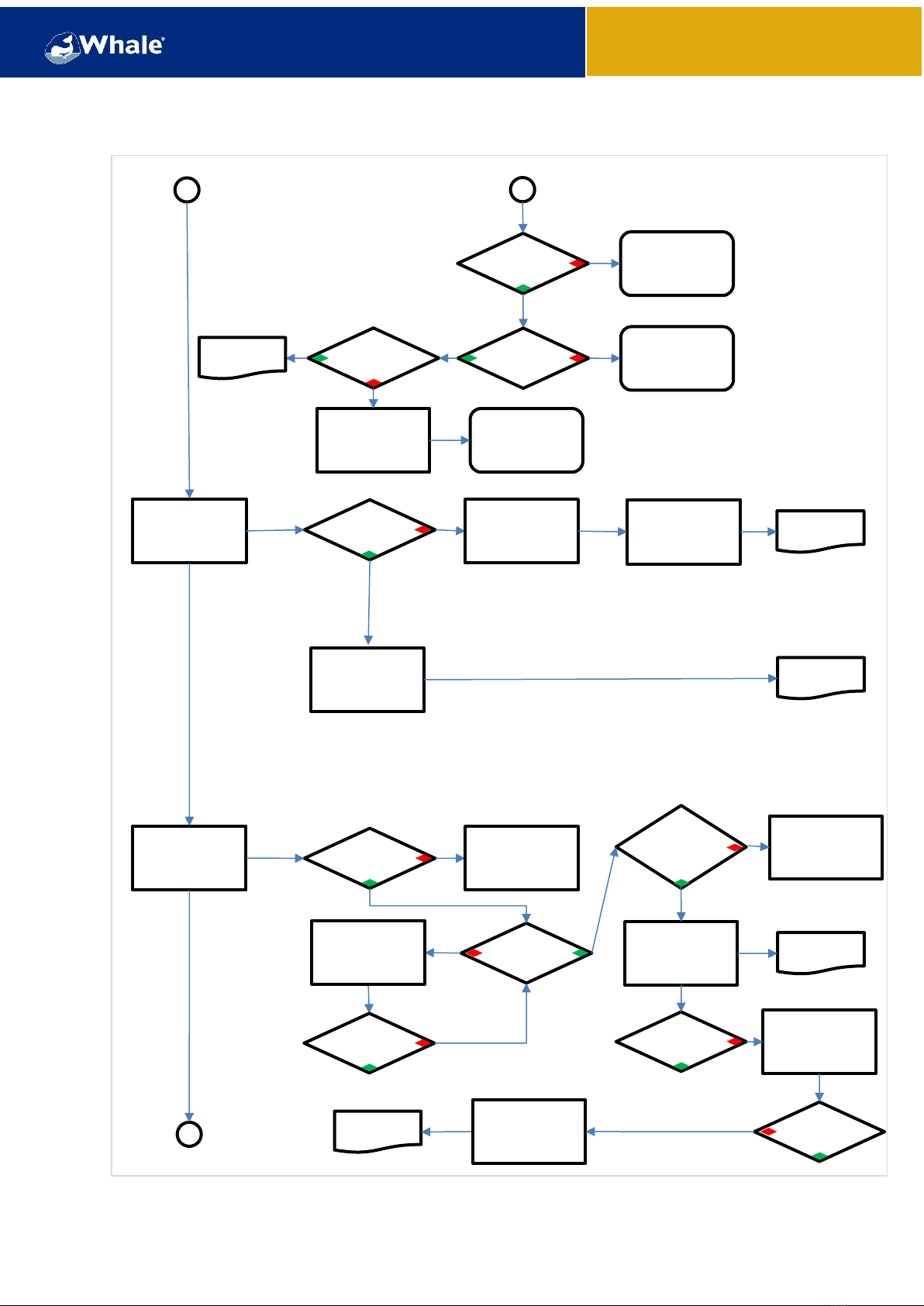

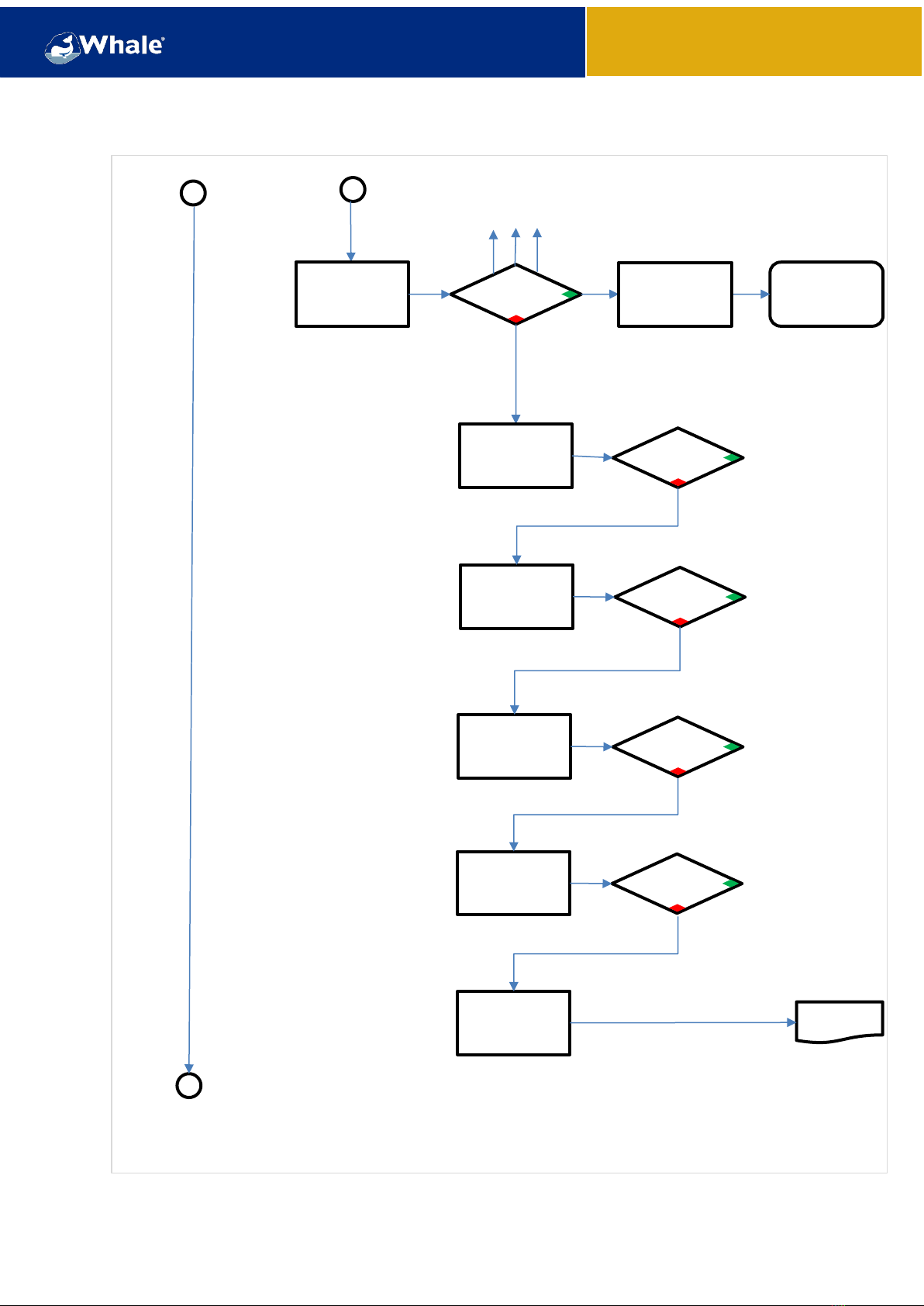

3.0 Fault Trees.........................................................................................................................................6

4.0 Troubleshooting..............................................................................................................................11

4.1 Lock outs/Fault codes .................................................................................................................11

4.1.1 Clear lockout procedure Heat and Duo Control Panel.........................................................11

4.1.1.1 –1 Bar: No flame detected...............................................................................................11

4.1.1.2 –2 Bars: Overheat.............................................................................................................12

4.1.1.3 –3 Bars: Low/High supply voltage....................................................................................12

4.1.1.4 –4 Bars: Combustion air fault...........................................................................................13

4.1.1.5 –5 Bars: Room Heater issues............................................................................................13

4.1.1.6 –All Bars: Multiple faults..................................................................................................13

4.1.2 Clear lockout procedure iVan Control Panel........................................................................14

4.2 Whale returns procedure............................................................................................................15

4.3 Initial steps required before replacing internal parts.................................................................17

4.4 Replacement of Blown Air Fan - AK1834 ....................................................................................17

4.5 Replacement of Gas Control PCB –AK1845, AK1846, AK1847...................................................18

4.6 Replacement of Electric Control PCB –AK1849..........................................................................19

4.7 Gas Component Replacement ....................................................................................................20

4.7.1 Replacement of Solenoid Coils –AK1842, AK1843, AK1844....................................................20

4.7.2 Replacement of Motor Units ...................................................................................................21

4.7.3 Replacement of Burner Assembly 4.0KW –AK1839/ Electrode AK1841.................................22

4.7.4 Replacement of Gas Heat Exchanger –AK1840.......................................................................23

4.8 Gas Overheat (O/H) Thermostat check and replacement - AK1854...........................................23

4.9 Temperature Sensor Gas–AK1852, Gas & Electric AK1853 check and replacement.................24

4.10 Assessment and replacement of Electric Element AK1850 ......................................................25

5.0 Spare parts......................................................................................................................................26

6.0 Contact details ................................................................................................................................29