- 10

SAFETY PRECAUTIONS

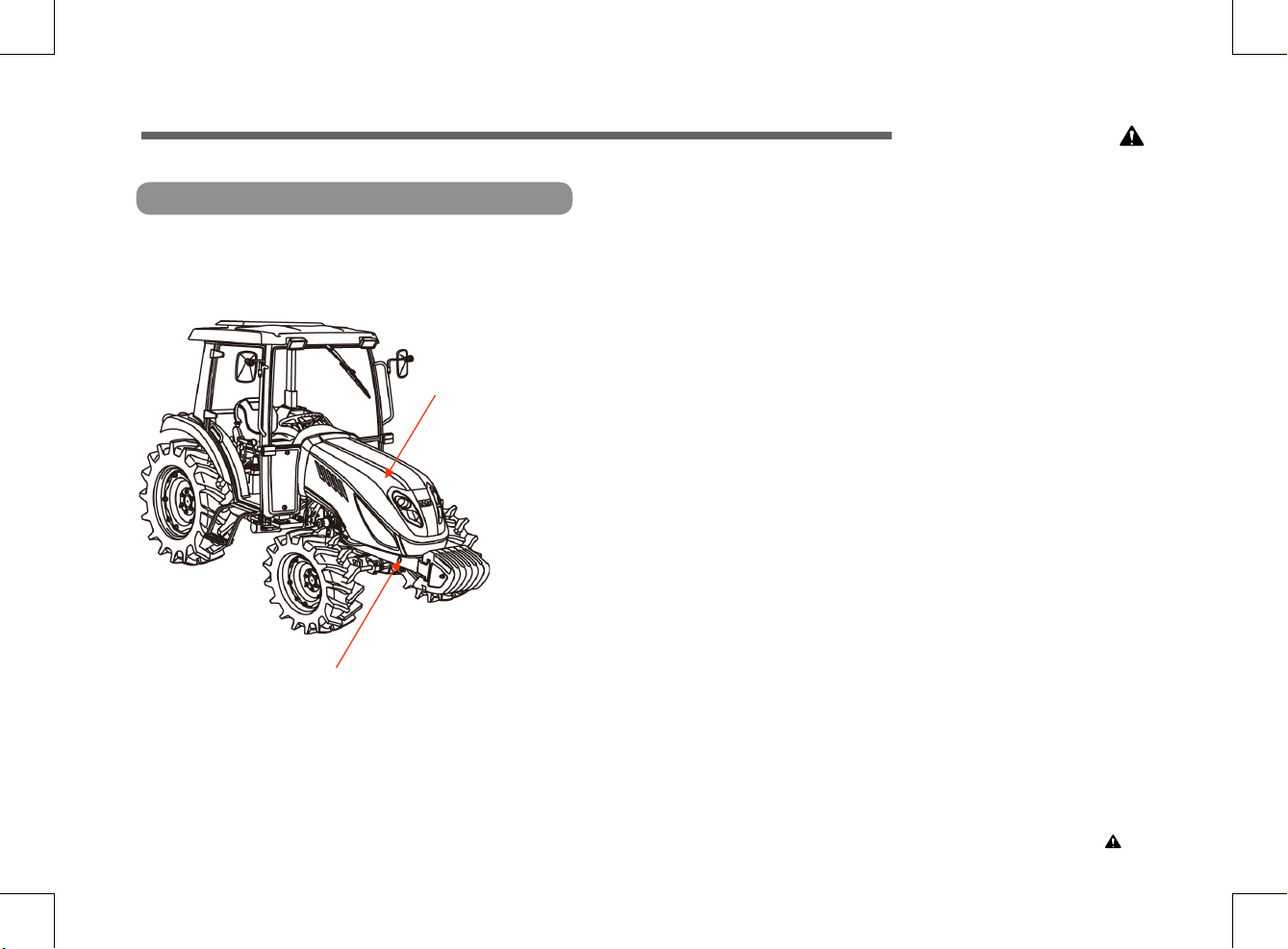

Roll Over Protective Structures

(ROPS)

TYM Tractors are equipped with a frame for

the protection of operators.

In the case of cab tractors the frame is incor-

porated in the cab structure.

The objective of the frame or cab structure is

to protect the operator in the event of a roll

over and they are designed to support

the entire weight of the tractor in that event.

Each TYM ROPS frame or cab structure is

designed and has been tested to meet industry

and or Government standards.

Included in these tests were all mounting bas-

es and bolts or other fasteners.

On some models the ROPS frame has a

fold down feature, which can be used to

enter low buildings etc Take care when

lowering

the upper section of the ROPS frame and

take extreme care while driving the trac-

tor with the ROPS frame lowered.

Do not wear the seat belt with the ROPS

lowered and please remember that the

fold down facility is for special circum-

stances

only and must not be lowered for general

use.

Use of the tractor with the ROPS low-

ered can cause fatal injuries.

As the ROPS frame or cab together with the

seat belt was designed to meet certain stan-

dards, they must be maintained in good

order and condition. To achieve this objective,

both the structure and the seat belt should be

inspected on a regular basis (every

time the tractor is serviced)

In the event that the seat belt is damaged or

frayed, it should be replaced and in the event

that the ROPS frame or any part of the

mounting structure is damaged or cracked,

the faulty component must be replaced with a

new unit. Such a unit must meet all of

the test criteria of the original unit .Fitment of

an inferior item or items affects the certica-

tion of the entire ROPS structure and

the effectiveness of the structure in the event

of an accident. Drilling or welding of the

ROPS structure is forbidden.

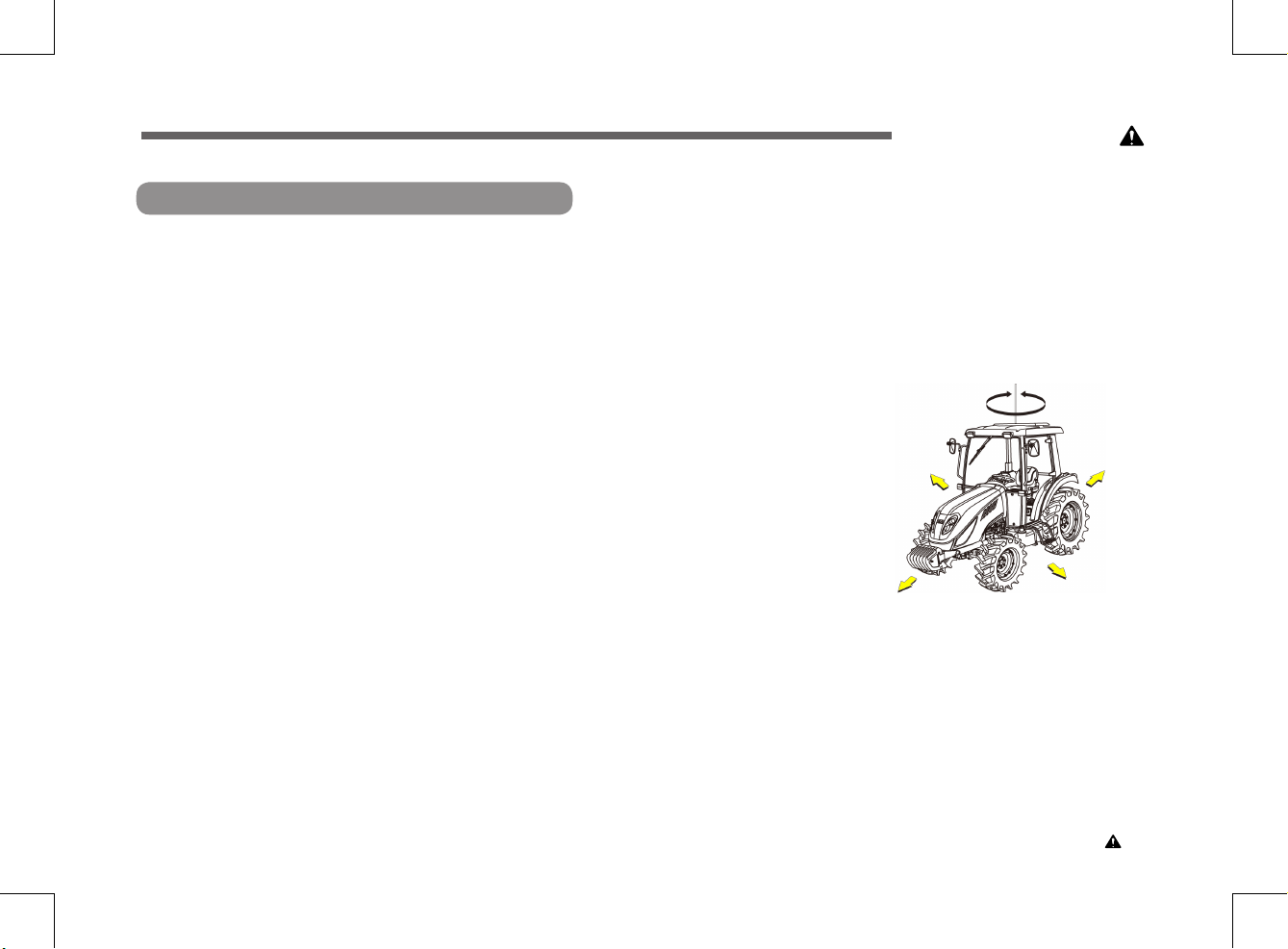

(ROPS) Roll Over Protective Structures

• For ROPS frames to be effective

and protect the operator, the seat

belt provided must be worn in order

to keep operators within the ROPS

protected area in the event of a roll

over. Failure to use the seat belt can

still cause serious injury or death.