3

ToolScope

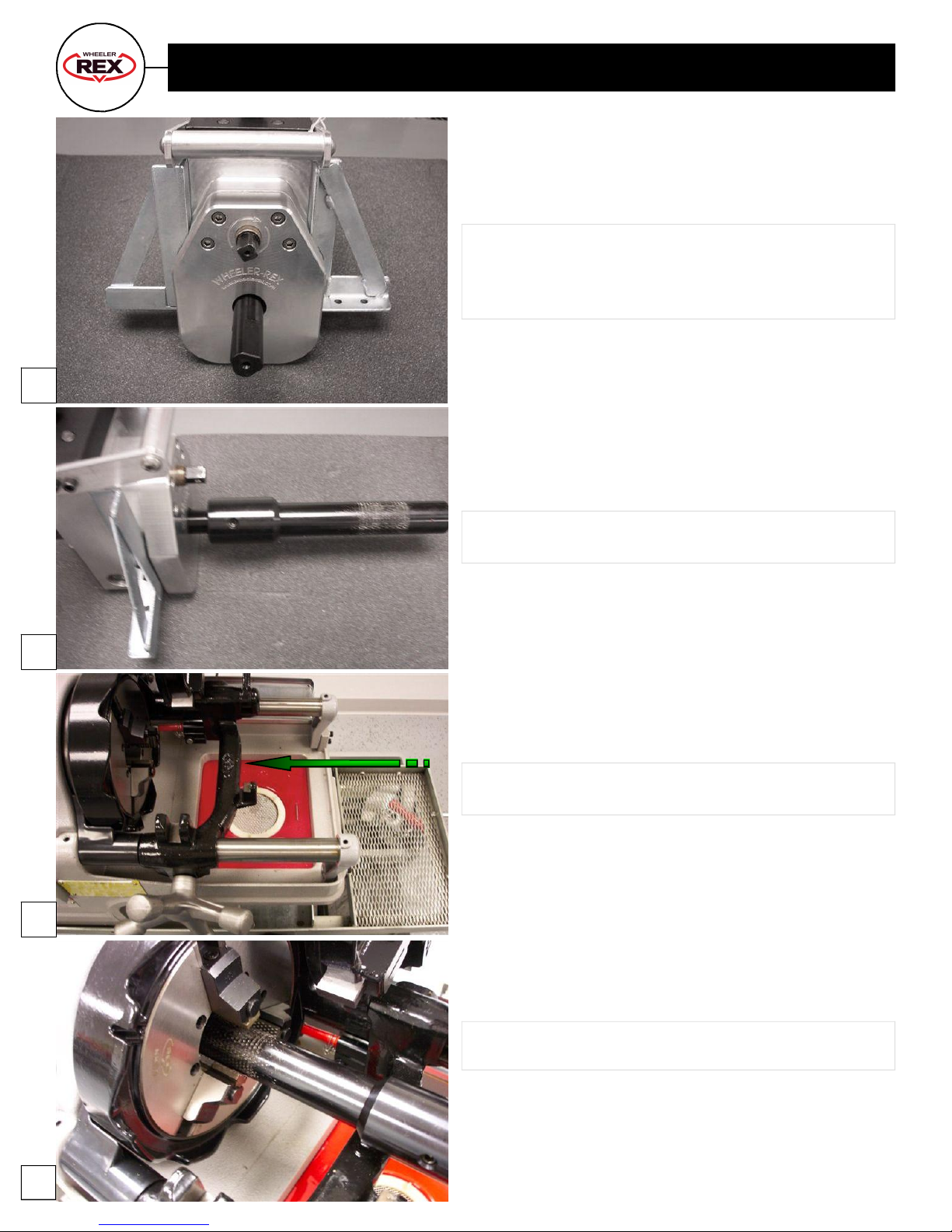

TheWheelerRexModel6600RollGrooverisdesignedtoformstandardrolledgroovesinsteelandstainless

steelpipe(seepipecapacityspecifications);byeitherusingapowersourceormanually.The6600RollGroover

hasbeendesignedfor‘jobsite’stylework,notfabshoporproductionwork.Withtheratchet,youcaneasily

rollgroovepipemanually.It’swiththeextremelightweight,durabledesignthatmakesthistoolportableandeasy

touseoverhead.

Important–ReadBeforeOperating

Beforeoperatingthe6600RollGroover,readandfollowallsafetyinformation,instructionsinthismanual.

PersonalSafetyInformation

·Seriousinjuriescanoccurifalloperatinginstructions&safetyinformationisnotfollowed.

·Lossofbodypartsifglovesorclothingarecaughtinmovingparts.

·Eyeinjuriesduetoworkpiecechipsorthrownworkpiece.

·Brokenbonesfromfallenworkpieceorifmachinetipsover.

·Alwaysusepersonalprotectiveequipment,eyeglasses,safetyshoesandhardhat.

WorkAreaSafety

·Keepworkareacleanandclearofdebris.

·Keepfloordryandfreeofoiloranyslipperyliquid.

·Makesureyourworkareaiswelllit.

·Keepbystandersandchildrenawayofworkareafortheirandyoursafety.

ElectricalSafety

·Inspectcordendsforfrayedandbrokenends.Neverpulloncord.Keepawayfromsharp

objectsandexcessiveheat,andmovingparts.

·Donotuseadaptersonplugends.Plugendsshouldmatchoutlets.

·Donotusepowertoolsinwetconditions.UseaGFCIifoperatingindamplocations.

·Alwaysuseasuitableextensioncordforoutdooruse.

GeneralSafety

·Readandunderstandallinformationinoperationmanual.

·Besuretoknowallfunctionsandlocationofallfeaturesontoolpriortooperation.

GeneralMaintenance

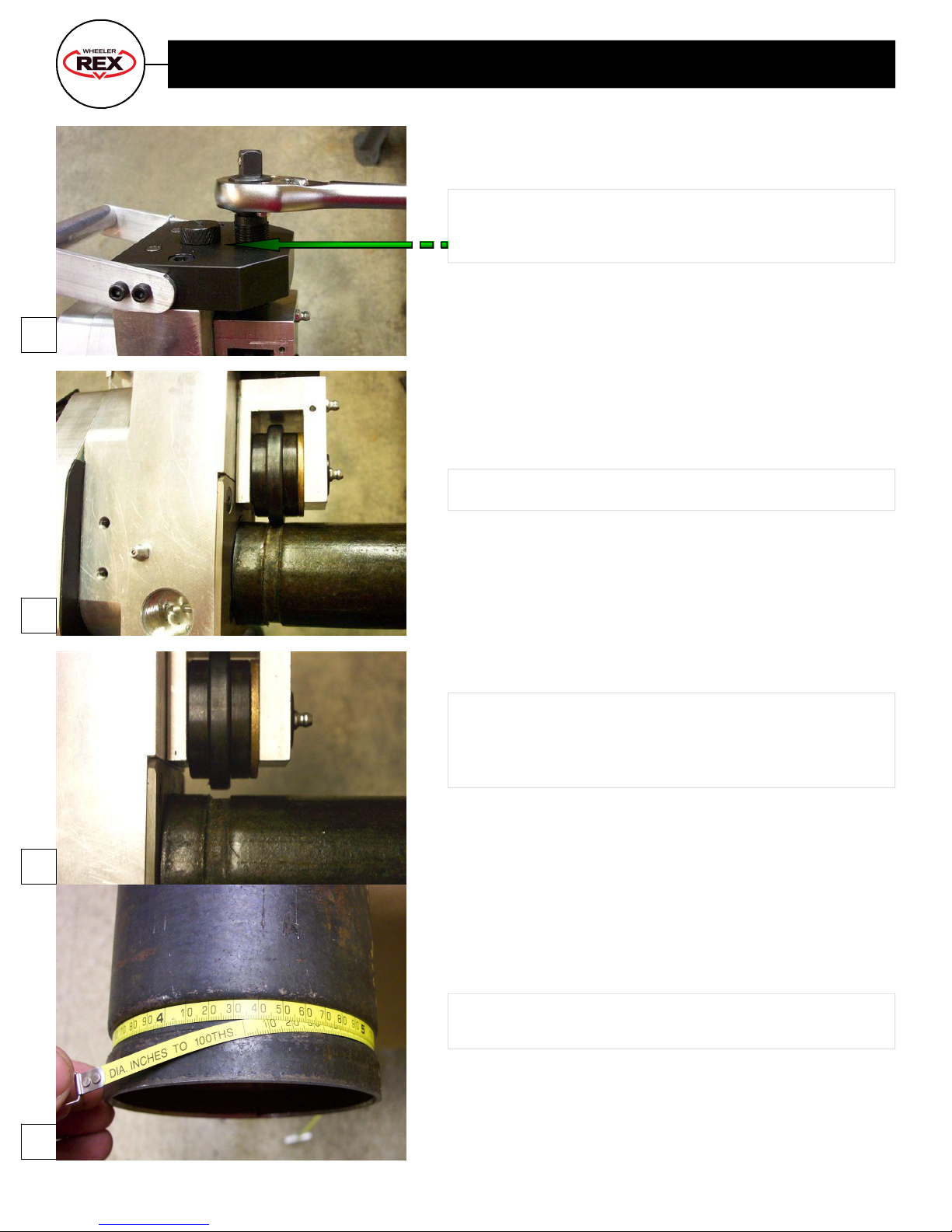

·Priortoeachuse,inspectbothshaftandroller.Replaceifwornordamaged.

·Inspectallothermovingparts.Replaceifwornordamaged.

·Withmultipurposegrease,lubricaterollgrooveratallthreegreasefittings.

·Refertothreadingmachinemanualformaintenancepertainingtothispowersource.

ToolUseandCare

·Storeunusedtoolsawayfromchildrenoranyotheruntrainedpeople.

·UseonlyWheelerRextoolswithorincombinationwiththistool.

·Doregularmaintenanceinspections,lubricatetoolandcheckformisaligned,looseorbindingparts.

·Neverforceoroverfeedthistool.Useaccordinglytoprintedinstructions.

·AlwayshaveyourtoolservicedbyanauthorizedWheelerRexServicecenter.

OtherRecommendedAccessories

·WheelerRex#71DiameterTape

·WheelerRex#4160TripodViseStand

·WheelerRex#851FoldingTripodPipeSupportw/heavydutyballtransferhead

PipeCapacitySpecifications

·1¼”–6”Schedule10steelpipe

·1¼”–6”Schedule40steelpipe

·1¼”–6”Schedule10stainlesssteelpipe

Important Information