4

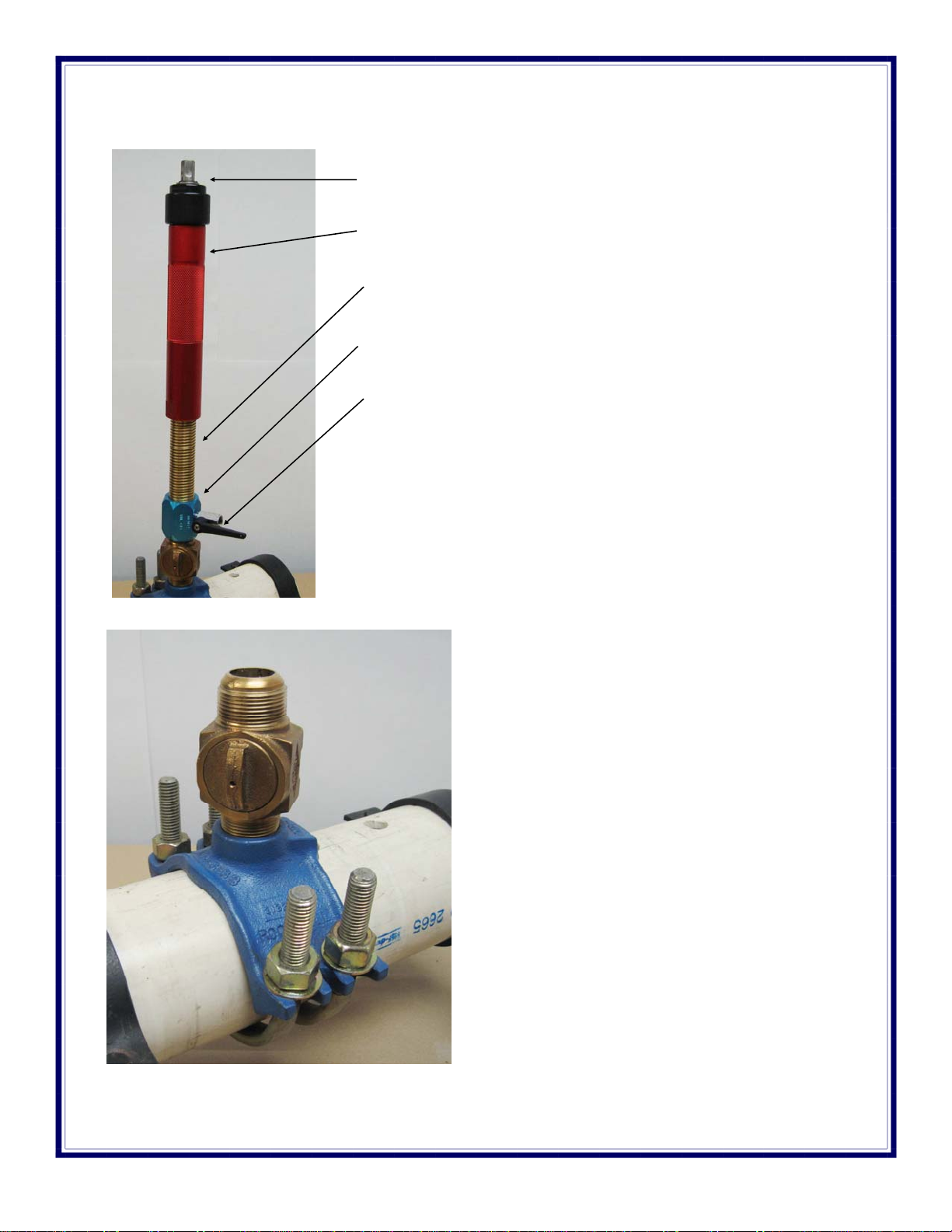

1. SLIDE HOT TAP SLEEVE (“B” FIG)

DOWN TO ENGAGE THE THREADS

OF THE HOT TAP FEED SCREW.

2. TURN HOT TAP SLEEVE

CLOCKWISE UNTIL SHELL CUTTER

TOUCHES PIPE.

3. USING THE SOCKET AND

RATCHET, ROTATE THE HOT TAP

SPINDLE (“A”FIG1) CLOCKWISE

WHILE CONTINUALLY APPLYING

PRESSURE. (BY TURNING THE HOT

TAP SLEEVE (“B”FIG1).

4. DRILL THROUGH THE PIPE UNTIL

NO RESISTANCE IS FELT WHEN

ADVANCING THE HOT TAP SLEEVE.

F5

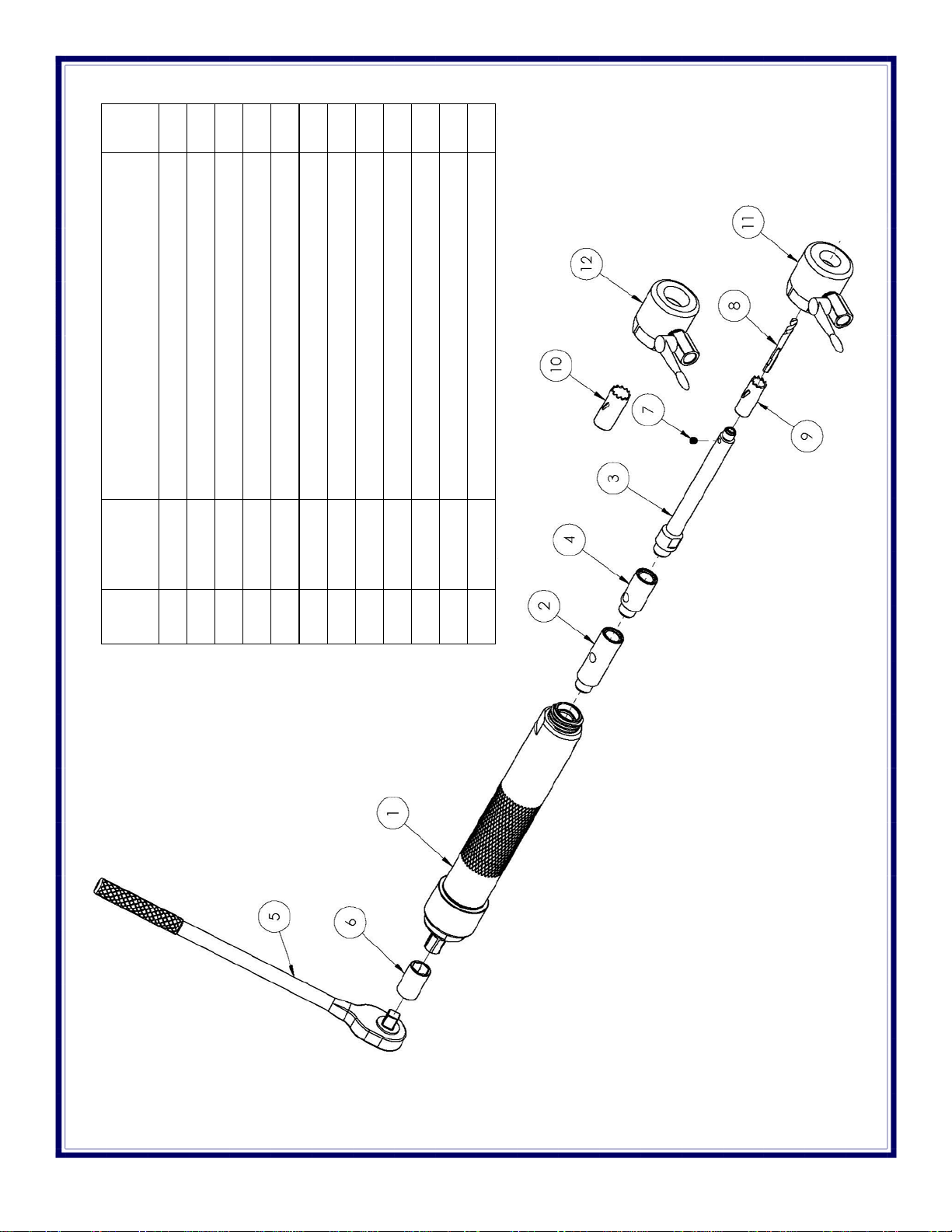

F61. AFTER HOLE IS DRILLED THROUGH

THE PIPE, RETRACT HOT TAP

SLEEVE BY TURNING COUNTER-

CLOCKWISE.

2. DISENGAGE THREADS AND PULL

UP ON HOT TAP SLEEVE TO

ENSURE PROPER CLEARANCE

BETWEEN HOT TAP SHELL

CUTTER AND CORPORATION STOP.