Page 4

The UPS64LX Strobe Power Supply, like all Whelen com-

ponents, can be installed in many different types of vehicles.

The guidelines for the installation of this product are written

so that no matter what vehicle is being used, the installation

and operation of the UPS64LX will be simple and straight

forward.

Selecting a Mounting Location...

The most common choice for a mounting area would be a

trunk or similar compartment. However, due to the wide

variety of vehicles onto which the UPS64LX could be

installed, this is not always possible. The following

guidelines will help the installer select an acceptable

alternative:

A) The UPS64LX™ should be mounted on a metal surface

to aid heat dissipation. Be sure that this surface is not

one that either generates or is exposed to excessive

heat during normal operation of the vehicle.

B) Do not select a location where the UPS64LX™ will be

exposed to potential damage from any unsecured or

loose equipment in the vehicle.

C) Be sure the area selected will not allow the UPS64LX™

to be exposed to water!

D) When routing the UPS64LX’s wires, it is important to

choose a path that will keep these wires away from

excessive heat and from any vehicle equipment that

could compromise the integrity of the wires (ex. trunk

lids, door jams, etc.).

E) When the best mounting location has been determined,

securely fasten the UPS64LX™ to it’s mounting surface

using the supplied hardware.

WARNING: The Strobe Light Power Supply is a high voltage

device. Do not touch or remove tube assembly in strobe light

head assemblies while in operation. Wait 10 minutes after dis-

connecting the unit from its power source before starting work or

troubleshooting on power supply or system.

CAUTION: As it will be necessary to drill holes into the mounting

surface, the installer MUST be sure that no vehicle components

or other vital parts could be damaged by the drilling process.

Check both sides of the mounting surface before drilling begins!

Installation...

1. Position the UPS64LX in its proposed mounting location to

ensure that it fits properly. With the UPS64LX™ in place,

insert an awl or other suitable tool into the mounting screw

area of the power supply and scribe the areas to be drilled.

2. Remove the UPS64LX™ from its mounting area and, using

a drill bit sized for a #10 sheet metal screw, drill a hole in

each of the areas scribed in the previous step.

3. Return the UPS64LX™ to its mounting location and using

the supplied #10 sheet metal screws, mount the

UPS64LX™ onto its mounting surface.

WARNING: All customer supplied wires, that connect to the

positive (+) terminal of the battery, must be sized to supply at

least 125% of the maximum operating current, and fused “at the

battery” to carry the load!

Wiring...

2. Connect the RED wire to a fuse block (customer supplied)

and then to the POSITIVE terminal on the battery.

NOTE! Although a 15 amp fuse (customer supplied) is required

to be used in the fuse block, do not install the fuse until all of the

wire connections are completed.

3. Connect the BLACK wire to the factory chassis ground

adjacent to the battery.

CAUTION: Reversing polarity (Reversing Positive and Ground-

wires) during the installation of a strobe light power supply, will

blow either the 15 amp fuse incorporated into the unit, or the

inline 15 amp fuse located on the positive (+) wire connected to

the power source.

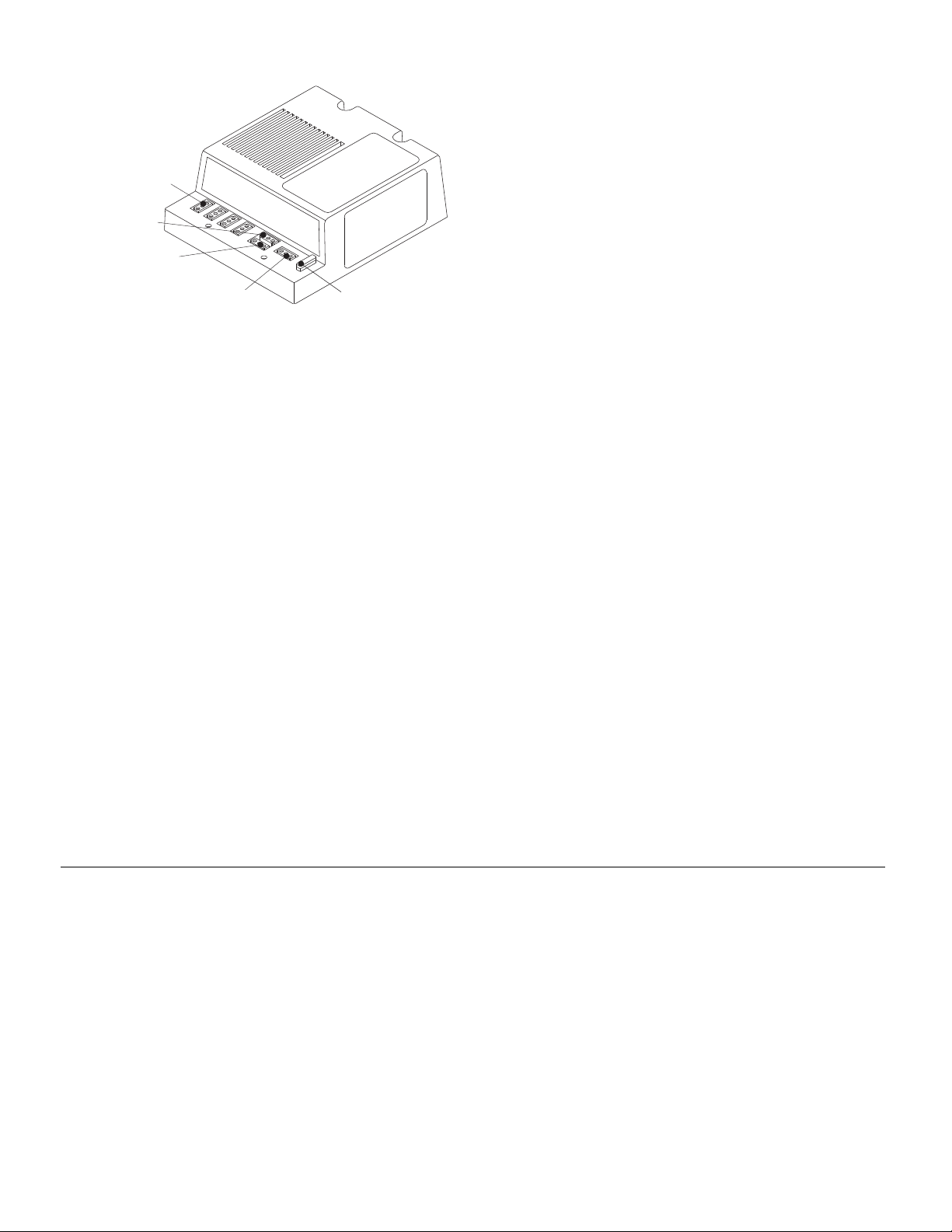

3POSITION

STROBE LIGHT

CONNECTORS

3POSITION

CONTROLCONNECTOR

3POSITION

PATTERN SELECTION

CONNECTOR

3POSITIONSOCKET

POWERINPUT CONNECTOR.

15 AMPFUSE FOR STROBE

POWERSUPPLY PROTECTION

UPS-64LX

POWER SUPPLY

™

The Micro-Edge™

is a dual Xenon tube, 270º remote strobe light head assem-

bly. Each unit is either designed for left or right side mounting

on vehicle. The cable assembly used to connect the Micro-

Edge™ light head assemblies to the Model UPS-64LX™

Strobe Light Power Supply, is a 6 conductor cable 20 feet

long. One end of the cable is connected on the inside of the

Micro-Edge™, and on the other end to factory installed 3 pin

connectors. Each one of the Micro-Edge™ light head assem-

blies is labeled underneath to indicate on which side of the

vehicle they should be mounted. When connecting the con-

nectors to the strobe light power supply, observe the color

coding and proper positioning of these connectors.

(See Wiring Diagram, Page 2.)

NOTE: During installation, when passing the cable through metal

surfaces, remove the burrs from the edges of the holes and if

possible use rubber grommets to protect the cable. It is also

advisable to support the cable with ty-wraps, cable clamps, or

any other means to prevent the cable from shifting around or

putting tension on the connectors.

The wiring assembly which connects the UPS-64LX™ strobe

power supply to the switch control assembly is a 5 conductor

cable assembly, 8 feet long.