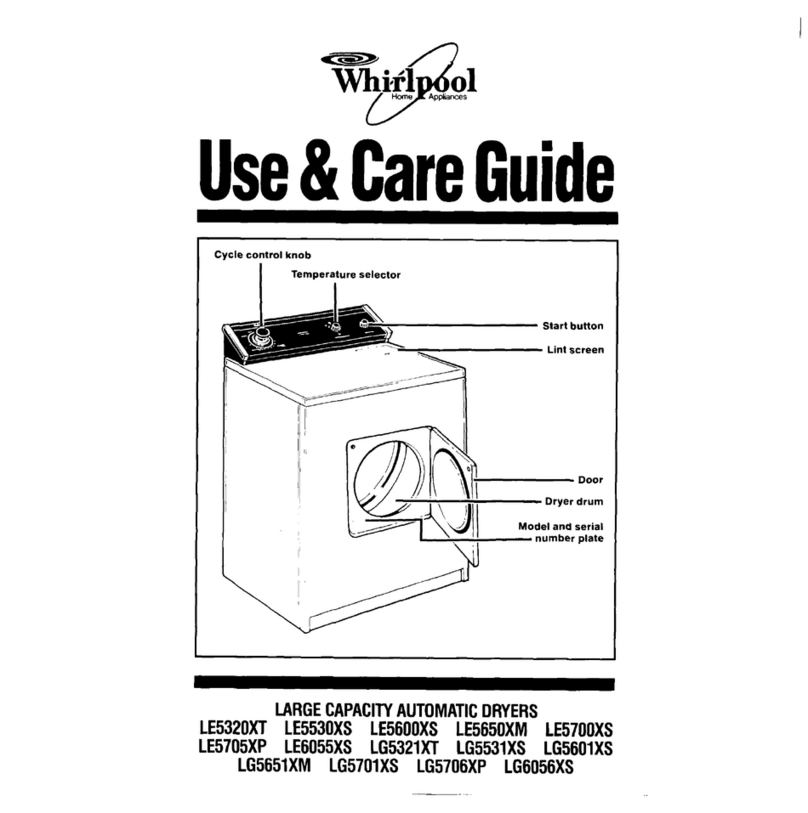

5. Exhaust outlet at rear of dryer IS located as shown In

Figure 4. Detailed instructions on spacing for side and

rear clearances can be found In the sectlon “Recessed

and Closet Instructions.“ Also mInImum spacing to side

and rear information is located on a separate label (found

on rear panel).

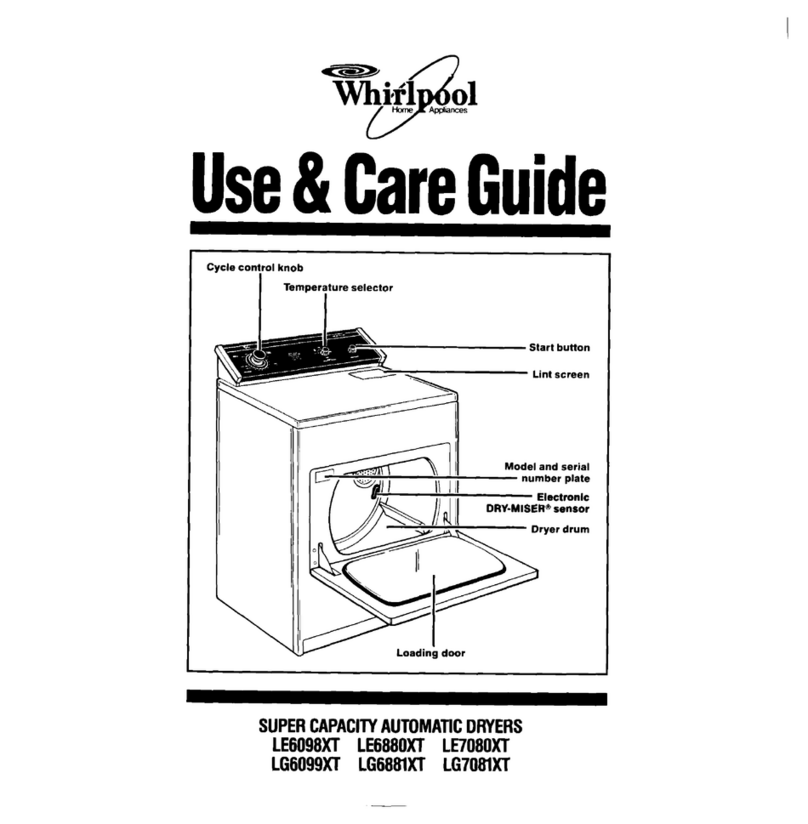

13. We do NOT RECOMMEND non-metalllc flexible duct.

If you use non-metallic flexible duct you must connect a

METAL elbow and at least 2 feet of METAL duct to the

dryer outlet. The length of the non-metallic flexible duct

should not exceed 7 feet, and It must be adequately

supported to prevent sagging or klnking See FIG. 6.

?ypical E%hauSt Installations

11.15/16” 4” DIA

d&&l

---/. t

3.5132”

Figure 4

6. If you wish IO permanently install the portable dryer,

a

stationary exhaust system is recommended.

7. We strongly recommend exhausting with 4 inch dlame-

ter rigid METAL duct. We strongly recommend METAL

flexible duct if you use flexible duct. NEVER

USE

SMALLER THAN 4 INCH EXHAUST DUCT.

8.The exhaust may

be routed up, down, left. right or

straight through the wall.

9. The exhaust duct should terminate with an exhaust

hood to prevent back drafts. The outlet of the hood must

be at least 12 inches from the ground or any obstruction.

An exhaust hood with a 4 inch outlet is preferred because

it creates less back pressure. A louvered exhaust hood

for 4 inch duct is also recommended. An exhaust hood

with a

2’12

inch outlet creates more back pressure, but

may be Lised with shorter systems. Never use an exhaust

hood with a magnetic latch.

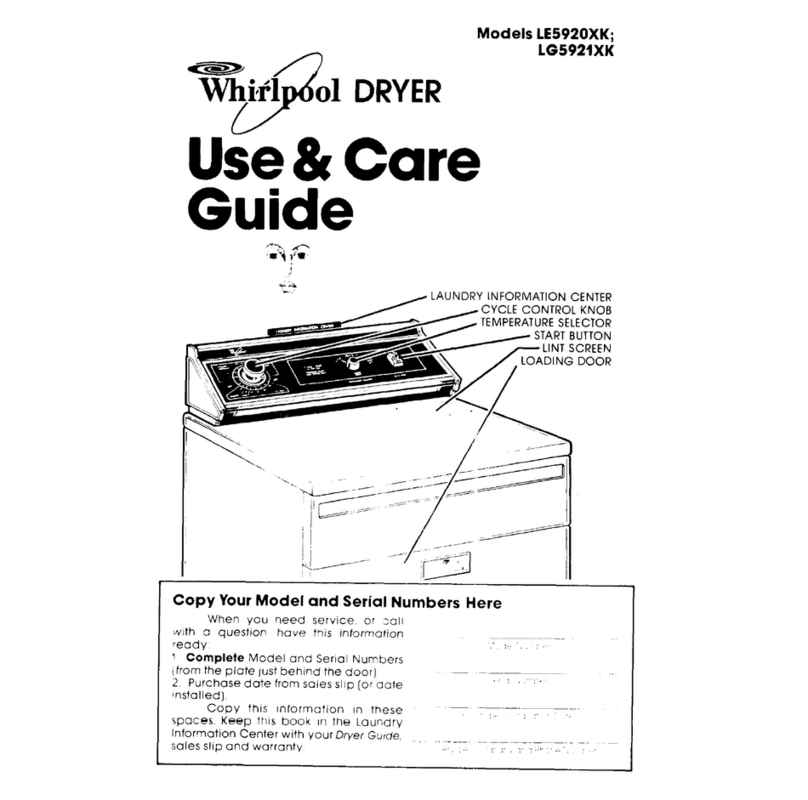

lO.The maximum length of the exhaust system depends

upon the type of duct used, the number of elbows and the

type of exhaust hood. The maximum length for both rigid

and flexible duct is shown in the chart, FIG. 5.

EXHAUST HOOD TYPE

:Y,“,‘::’ p--&@ gb-

MAXIMUM

0 43 Fr. 41 FT. 36 FT. LENGTH OF

1 33 Fr. 31 Fr. 26 FT. 4- DIA.

2 23 FT. 21 FT. 16 FT. RIGID METAL

DUCT.

MAXIMUM

0 30 FT. 29 FT. 24 FT. LENGTH OF

1 24 FT. 23 IT. 16 FT. 4’ DIA

2 16Fl. 15Ff. 10 FT. FLEXIBLE

METAL DUCT.

L

Figure 5

11. Use duct tape to seal

all

joints. Never use screws to

assemble

the ductwork, screws can catch lint.

12. Exhaust

systems

longer

than specified will shorten

the life of the dryer and result in reduction of perform-

ance such as longer drying

time and increased use of

energy. Lint may also accumulate creating a possible

safety hazard.The exhaust system must be cleaned

Periodically, at least every two years.

EXHAUST HOOD ‘1

J

RECOMMENDED

IMPORTANT: PROPER

SUPPORT IS REOUIRED

I - - . . - , . .

DUCTING NOT T

EXCEC” 7 C.zCT

ALTERNATE

Figure 6

NEVER INSTALL ANY TYPE OF FLEXIBLE DUCT CON-

CEALED IN WALLS OR CEILING

14. There are exhaust kits aizlable that allow the filtered

exhaust air to be directed inside to conserve energy

during winter months. Some of these kits cause restric-

tions or excessive back pressure and must NOT be used.

In some locations exhaust moisture may cause building

damage. If you use one of these kits you must maintain it

properly to avoid excessive lint build up which results in

reduced dryer performance. For continued proper opera-

tion the exhaust duct should be inspected periodically,

depending on use. Inspection and cleaning will help

prevent blockage of the exhaust system, reduced air

flow and long drying time. After inspection be sure

to reconnect the exhaust system properly, using

duct tape to fasten the joints.

15.Leveling feet (Part No. 233550) for use in permanent

installations are available at your Whirlpool dealer. Four

feet are required. The feet should extend about 1” below

the bottom of the dryer.

16. If you do not desire to install a permanent exhaust

system, you may purchase a Window Exhaust Kit (No.

LCK3000) from your WHIRLPOOL dealer. The Window

Exhaust Kit is designed to exhaust the dryer out of a

double hung window. Complete instructions are in-

cluded with the kit.

17. For mobile home installations the dryer must be

exhausted to the outside. If the dryer is exhausted

through the floor and the area

under the mobile home is

enclosed, the exhaust system must terminate outside

the enclosure. Extension beyond the enclosure will

prevent the accumulation of lint and moisture under

the mobile home. See Figure 7.

3