Ku nst sto ffschwei ßtec hni k

WIDOS Einsteinstr. 5 Phone +49 (0) 71 52 99 39 - 0

. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 (0) 71 52 99 39 - 40

ebsite: www.widos.de Email: info@widos.de

02.08.2011 orking Instructions IDOS 4900 CNC 3.5 Page 6 of 68

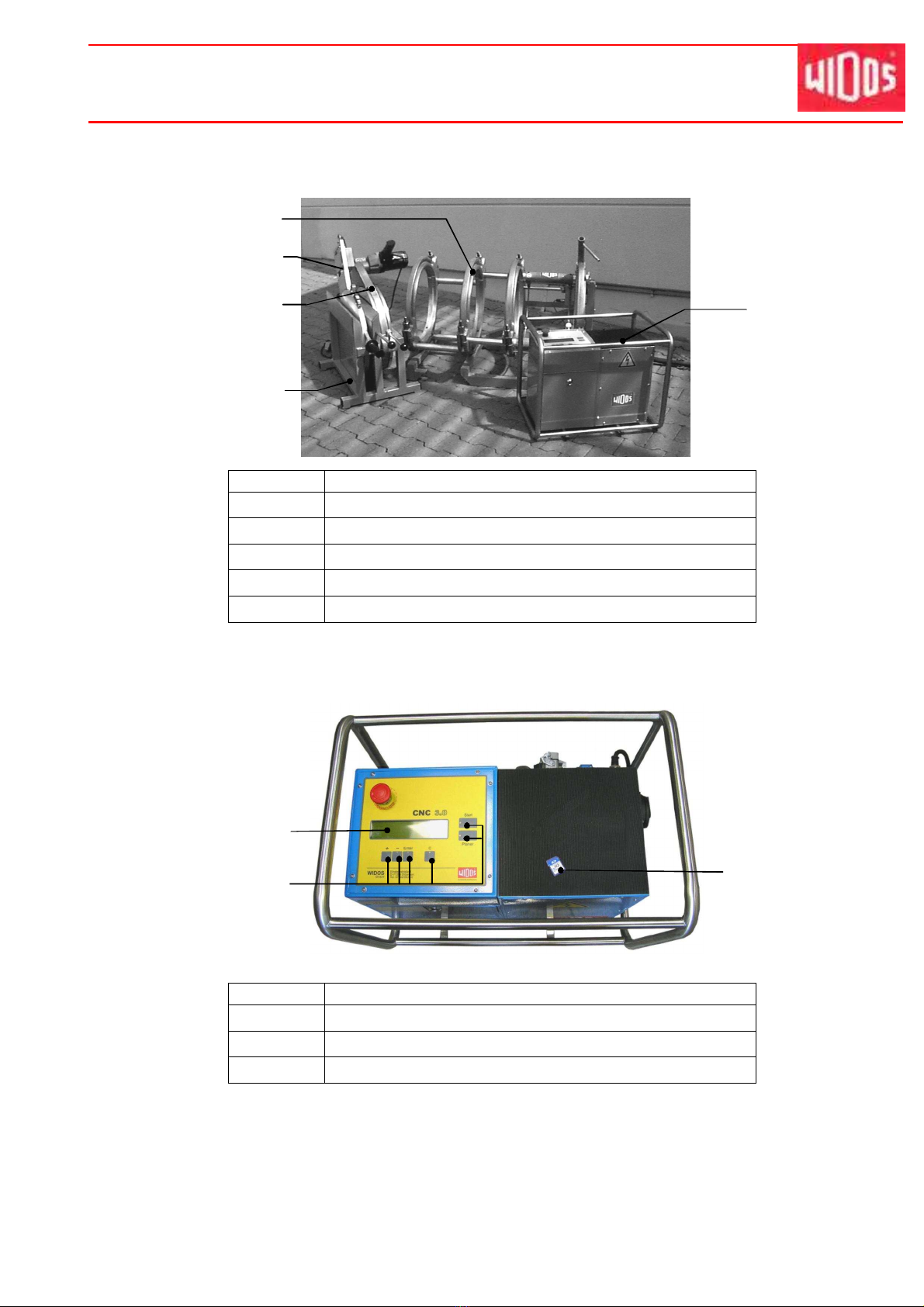

1. Description o the product

1.1. Usage and purpose-oriented Use

The WIDOS 4900 CNC 3.5 has been designed only for heating element butt welding of pipes

and fittings made out of the materials PE, PP, and PVDF with their diameter range going from

OD

min

= 90 mm up to OD

max

= 315 mm in the way as described below.

All use o this machine going beyond is not purpose oriented.

The machine is only to be used in a technically perfect condition, as well as purpose oriented,

safety- and danger-conscious in compliance with the working instructions and the relevant safety

regulations (especially the regulations for the prevention of accidents).

The described plastic welding machine may only be operated, maintained and repaired by

persons who are trained and informed about the dangers.

The manufacturer is not responsible for any damages caused by inexpert handling or operation.

For personal injuries, material and immaterial damages resulting herefrom, only the user is

responsible!

The control unit is reliable in the use when it is used according to the prescriptions in connection

with a welding machine designed by IDOS.

Also part of the purpose oriented use is

• respecting all the indications of the working instructions and

• performing the inspection and maintenance works.

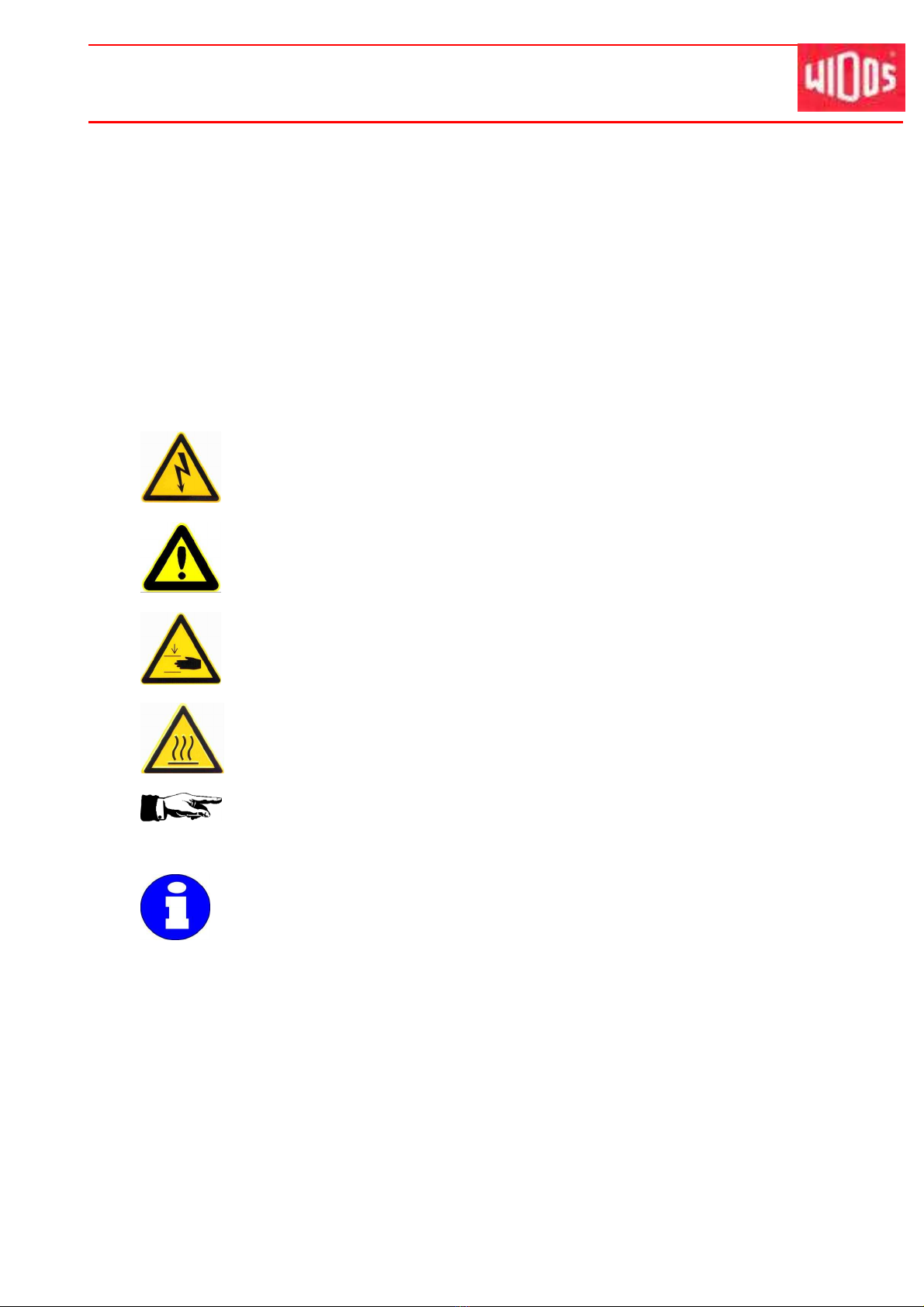

1.2. Sa ety measures

In case of wrong use, wrong operation or wrong maintenance, the machine itself or products

standing nearby can be damaged or destroyed.

Persons being in the endangered area may be injured.

Therefore these working instructions have to be thoroughly read and the corresponding safety

regulations must be necessarily adhered to.

1.3. Con ormity

The machine corresponds in its construction to the valid recommendations of the European

Community as well as to the according European standard specifications.

The development, manufacturing and mounting of the machine were made very carefully.