Contents

06/06/19 Working Instructions WIDOS HRG 6, Segment Page 4 of 47

1DESCRIPTION OF PRODUCT ............................................................................................... 6

1.1General.........................................................................................................................................6

1.2Safety measures...........................................................................................................................6

1.3Conformity ....................................................................................................................................7

1.4Designation of the product............................................................................................................7

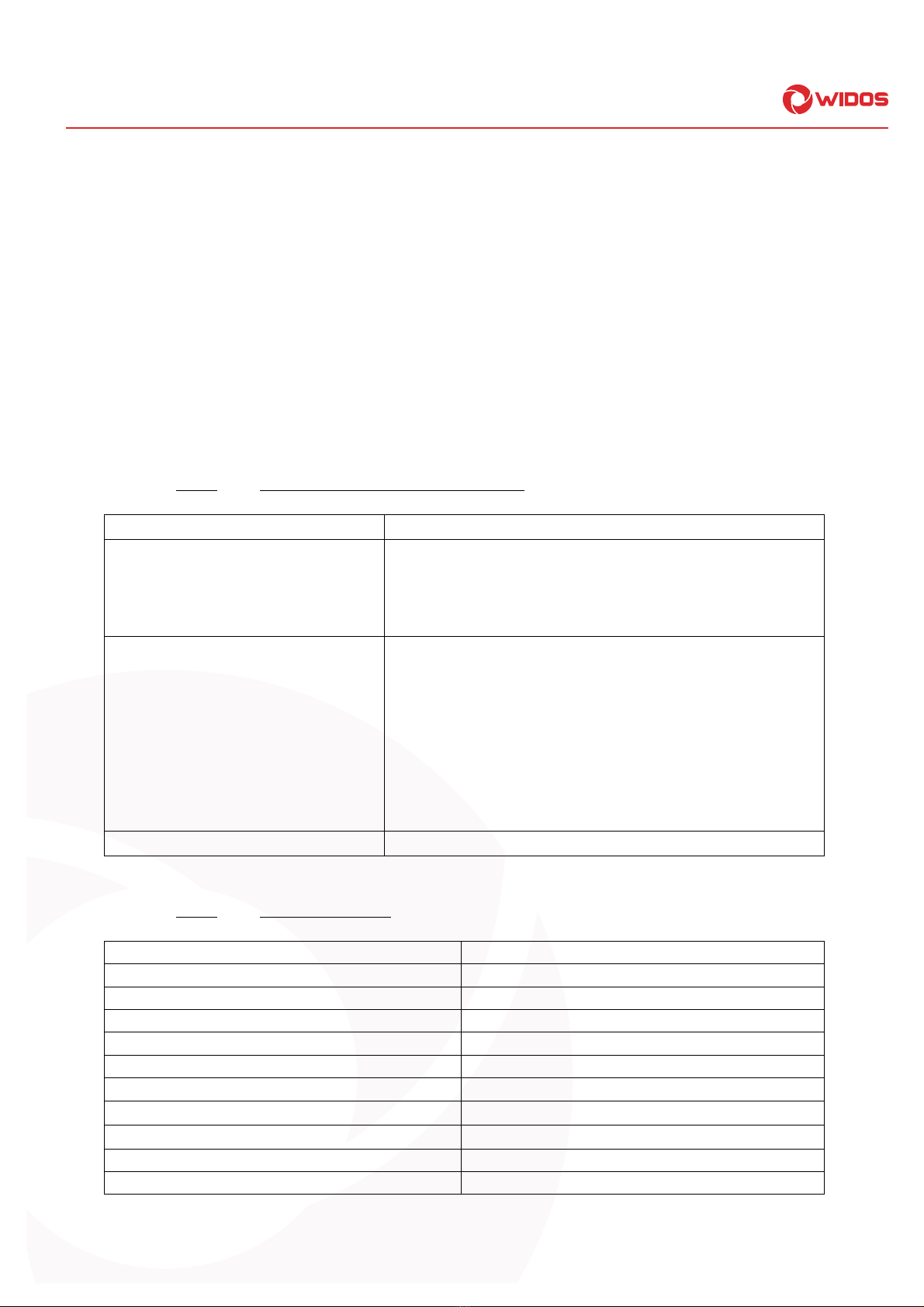

1.4.1Technical data ......................................................................................................................7

1.4.1.1WIDOS HRG 6, Segment general data ...............................................................................7

1.4.1.2Hydraulic aggregat............................................................................................................7

1.4.1.3Planer: .............................................................................................................................8

1.4.1.4Heating element................................................................................................................8

1.4.1.5Basic machine ..................................................................................................................8

1.4.1.6Reception box...................................................................................................................8

1.5Equipment and accessories ..........................................................................................................9

2SAFETY RULES................................................................................................................. 10

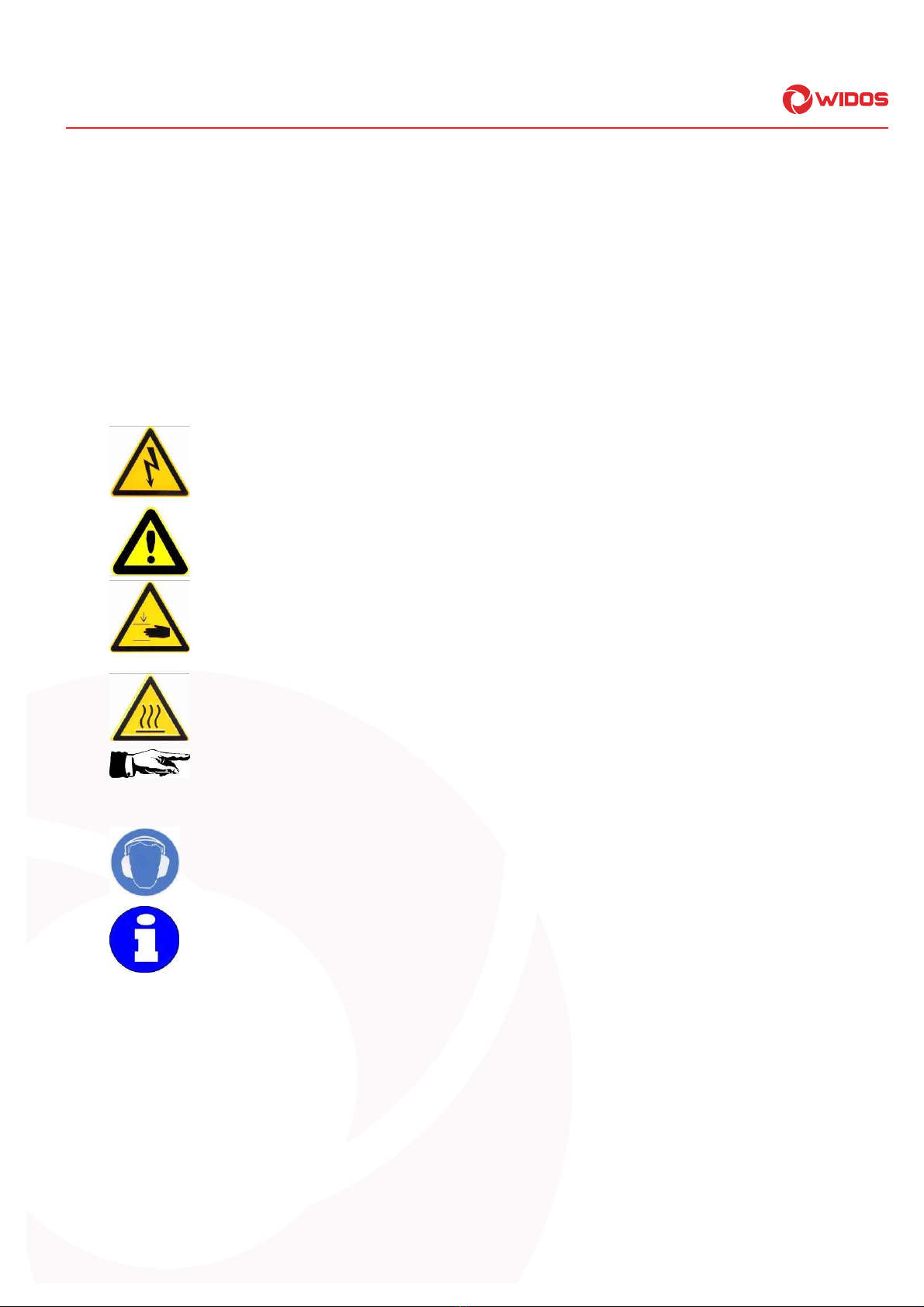

2.1Explanation of the symbols and indications................................................................................ 10

2.2Obligations of the owner ............................................................................................................ 10

2.3Obligations of the worker........................................................................................................... 11

2.4Measures of organisation .......................................................................................................... 11

2.5Information about safety precautions......................................................................................... 11

2.6Instructions for the staff ............................................................................................................ 11

2.7Dangers while handling the machine ......................................................................................... 11

2.8Dangers caused by electric energy............................................................................................ 12

2.9Specific dangers........................................................................................................................ 12

2.9.1Danger of combustion by heating element and welding area .................................................. 12

2.9.2Danger of stumbling over electric wires................................................................................ 12

2.9.3Danger of bruising by the guideways.................................................................................... 12

2.9.4Danger of bruising during planing ........................................................................................ 12

2.9.5Danger of noise .................................................................................................................. 12

2.9.6Danger of catching clothes by the planer.............................................................................. 13

2.10Structural modifications on the machine ............................................................................... 13

2.11Warranty and liability ............................................................................................................ 13

3FUNCTIONAL DESCRIPTION............................................................................................. 14

4OPERATING AND INDICATING ELEMENTS ....................................................................... 15

4.1Elements on the standard version .............................................................................................. 15

4.2Heating element ................................................................................................................. 16

4.3Planer........................................................................................................................................ 17

4.3.1How to work with the planer ................................................................................................ 18

4.4Angle setting at the clamping device ......................................................................................... 19