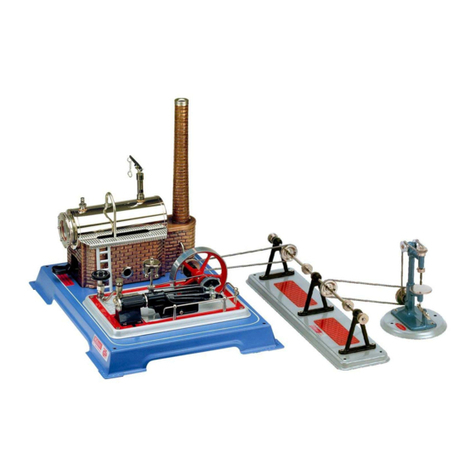

Assembly Instructions

Steam Roller D375, D376, D377 & Traction Engine D415, D416, D417

Stage 4, Flywheel shaft

Illustration 11

36 1 x machine plate

37 1 x flywheel

38 1 x pulley

39 1 x grub screw

40 1 x crank disk

41 1 x ex-centre plate

42 1 x collar screw Mw short

43 1 x spacer diam. 6x3mm

44 1 x slide rod

45 1 x brass cap

46 1 x washer 5.6/3mm

5 2 x hexagonal nuts M3

47 1 x hexagonal nut M4

7 4 x washers 8/4.5mm

48 1 x piston rod

49 1 x flywheel shaft

Illustration 12

This section must be assembled very carefully, as

the functioning of the steam engine is dependent

on it. The machine plate (36) is secured loosely

with the 2 nuts (5) onto the protruding screws of the

burner chamber cover. The fly wheel shaft (49) is

pushed through the bearings of the machine plate,

with the short thread on the right hand side. Fit 2

washers (7), the brass cap (45), and then a further

washer (7) to the left hand side of the shaft. Fit a

washer (7), ex-centre plate (41), and slide rod (44)

with bend towards the chamber and a further

washer (46) to the right hand side of the shaft.

Then screw the crank disc (40) onto the right hand

side of the shaft, using the middle threaded hole.

The piston rod (48) is attached to the crank disc by

means of the collar screw (42), with spacer (43)

fitted between piston rod (48) and crank disc (40).

Illustration 13

Now the flywheel (39) is pushed onto the left hand

side of the shaft with the pinion inwards. Screw

onto the thread a washer (7) and a nut (47) M4 so

that the shaft is slightly pulled inwards.

Tighten carefully all parts so that the crank disk is

firmly held in place.

IMPORTANT: The small pin of the ex-centre disk

(41) must move freely in the oval hole of the crank

Illustration 14

Tighten the M4 nut with the combination spanner

and move the flywheel along the shaft until the

pinion engages with the large gear wheel. Ensure

that the shaft is moving freely without the ex-centre

pin slipping from the oval hole in the crank disk.

Remove the nut M4 and the washer.