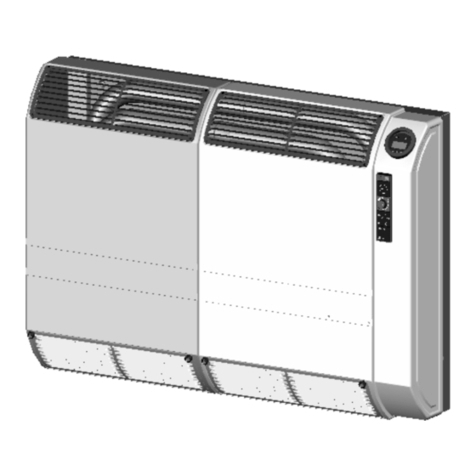

8TG2030TN TOP VENT GAS WALL HEATER

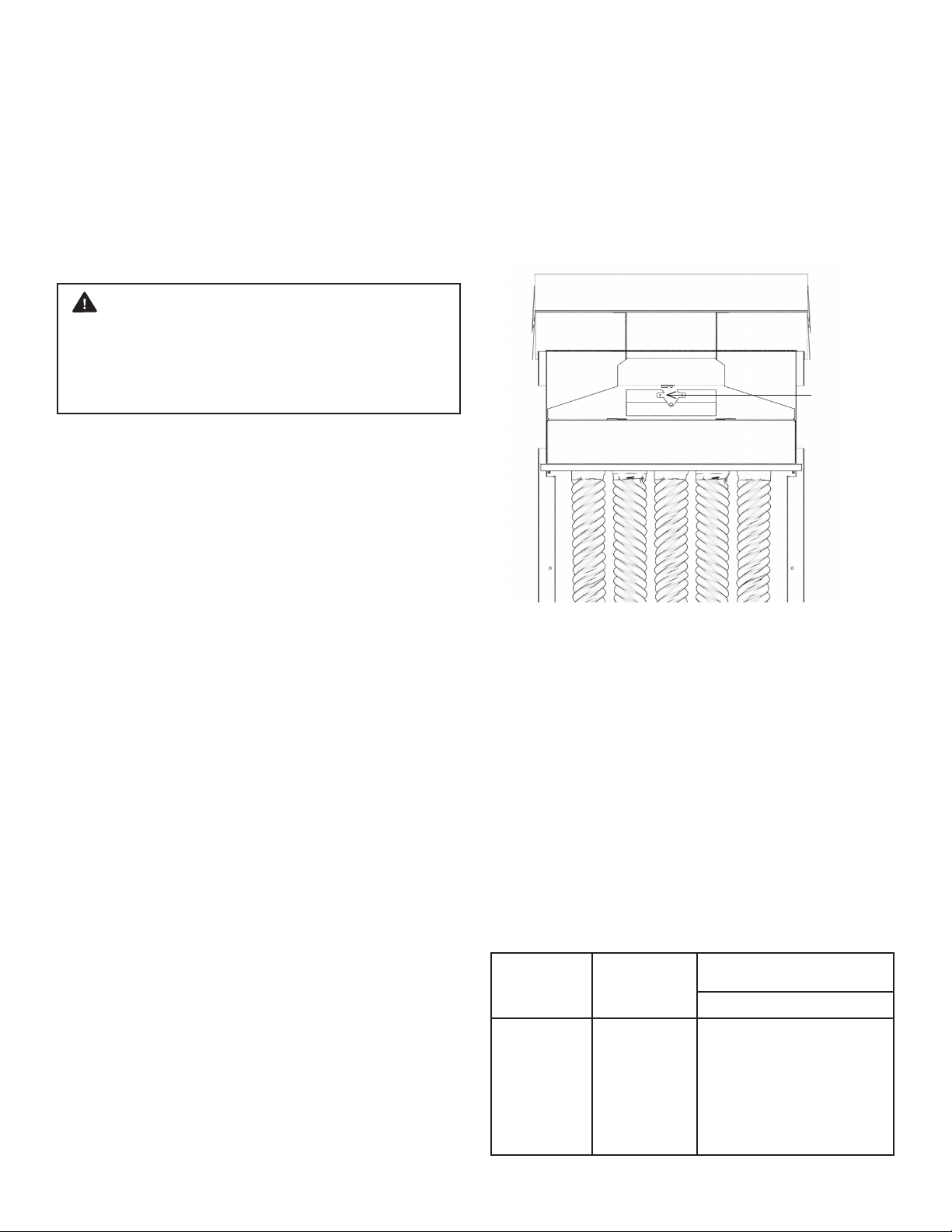

After picking a location that meets the requirements, check

the walls, attic and roof to make sure there are no obstructions

such as pipes, electrical wiring, etc., which could interfere with

the installation of the furnace or vent pipe. If required, move

them or pick a new location.

WARNING: Danger of property damage, bodily injury

or loss of life. Do not install the furnace in any area where

oxygen is in use.

Combustion & Ventilation Air

When an existing category I heater is removed or replaced,

the original venting system may no longer be sized to

properly vent the attached appliances.

WARNING: CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each appliance

connected to the venting system being placed into operation

could result in carbon monoxide poisoning or death.

The following steps shall be followed for each appliance

connected to the venting system being placed into operation,

while all other appliances connected to the venting system

are not in operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 or the Natural Gas and Propane

Installation Code, CSA 8149.1 and these instructions.

Determine that there is no blockage or restriction,

leakage, corrosion and other deficiencies which could

cause an unsafe condition.

3. As far as practical, close all building doors and windows

and all doors between the space in which the

appliance(s) connected to the venting system are located

and other spaces of the building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not connected

to the venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they are

operating at maximum speed. Do not operate a summer

exhaust fan.

6. Follow the lighting instructions. Place the appliance

being inspected into operation. Adjust the thermostat

so appliance is operating continuously.

7. Test for spillage from draft hood equipped appliances

at the draft hood relief opening after 5 minutes of main

burner operation. Use the flame of a match or candle.

8. If improper venting is observed during any of the above

tests, the venting system must be corrected in

accordance with the National Fuel Gas Code, ANSI Z223.1/

NFPA 54 and/or Natural Gas and Propane Installation

Code, CSA 8149.1

9. After it has been determined that each appliance

connected to the venting system properly vents when

tested as outlined above, return doors, windows, exhaust

fans, fireplace dampers and any other gashed burning

appliance to their previous conditions of use.

WARNING: Danger of property damage, bodily

injury or loss of life. The furnace and any other fuel-

burning appliances must be provided with enough fresh

air for proper combustion and ventilation of flue gases.

Most homes will require that outside air be supplied into

the heated area.

The high cost of energy for home heating has brought about

new materials and methods used to construct or remodel most

current homes. The improved construction and additional

insulation has reduced the heat loss and made these homes

much tighter around windows and doors so that infiltrated air

is minimal. This creates a problem to supply combustion and

ventilation air for gas-fired or other fuel burning appliances.

Any use of appliances that pull air out of the house (clothes

dryers, exhaust fans, fireplaces, etc.) increases this problem and

appliances could be starving for air.

The combination of a tight energy efficient home with the use

of exhaust fans, fireplaces, clothes dryers, and gas appliances

result in more and more air being drawn from the house until

fresh air may be sucked back into the house down a furnace

flue or fireplace chimney. Carbon monoxide can be the result.

Carbon monoxide (CO) is a colorless, odorless gas produced

when fuel is not burned completely or when the flame does

not receive sufficient oxygen. Automobiles, charcoal, wood fires

and improperly vented or air-starved coal, oil and gas furnaces

or other appliances can produce carbon monoxide.

Do not install furnace in the same room or near a wood solid

fuel burning fireplace.

BE AWARE OF THESE AIRSTARVATION SIGNALS:

1. Headaches, nausea, dizziness.

2. Excessive humidity shown by heavily frosted windows or

a moist “clammy” sensation.

3. Fireplace smoke fills the room or will not draw.

4. Furnace flue backs up.

AIR REQUIREMENTS

The requirements for providing air for combustion and

ventilation are listed in the National Fuel Gas Code NFPA

54/ANSI Z223.1 (in Canada: CAN/CGA B149). Most homes

will require that outside air be supplied to the heated area

by means of ventilation grilles or ducts connecting directly

to the outside or spaces open to the outdoors such as attic

or crawl space. The only exception is when the heated area

meets the requirements and definitions for an unconfined

space with adequate air infiltration.

All air openings and connecting ducts must comply with

the following: (continued on next page)

INSTALLING YOUR FURNACE