InstallationandoperatinginstructionsWilo-ControlMS-L2x4kW 29

SAFETY English

Inaddition,alltheothersectionscontainspecic

safety instructions and technical information.

Allinstructionsandinformationmustbeob-

served and followed during the various phases of

the switchgear life cycle (installation, operation,

maintenance,transport,etc.)!Theoperatoris

responsible for ensuring that all personnel follow

these instructions and guidelines.

2.1. Instructions and safety instructions

This manual uses instructions and safety in-

structions for preventing injury and damage to

property.Toclearlyidentifythemforpersonnel,

the instructions and safety instructions are dis-

tinguishedasfollows:

• Instructions appear in bold and refer directly to

theprecedingtextorsection.

• Safety instructions are slightly indented and bold

andalwaysstartwithasignalword.

• Danger

Serious or fatal injuries can occur!

• Warning

Serious injuries can occur!

• Caution

Injuries can occur!

• Caution (instruction without symbol)

Substantial property damage can occur. Irrepa-

rable damage is possible!

• Safety instructions that refer to personal injury

appear in black and are always accompanied by

asafetysymbol.Danger,prohibitionorinstruc-

tion symbols are used as safety symbols.

Example:

Dangersymbol:Generalhazard

Dangersymbol,forexample,electricalcurrent

Prohibitionsymbol,forexample,Keepout!

Instructionsymbol,forexample,wearprotec-

tive clothing

The safety symbols used conform to the gener-

ally applicable directives and regulations, such

asDINandANSI.

• Safety instructions that only refer to materi-

al damage are printed in grey, without safety

symbols.

2.2. General safety

• The electricity network must be switched off

before any work is performed (installation, dis-

mantling,maintenance).Theswitchgearmustbe

disconnected from the electricity network and

secured against reactivation.

• The person operating the switchgear must notify

his or her supervisor immediately should any

faults or irregularities occur.

• Where damage occurs to electrical components,

cables and/or insulation, the switchgear must be

shut down immediately by the operator.

• Tools and other objects should be kept in their

designated places so that they can be found

quickly.

• The switchgear may not be installed in potentially

explosiveareas.Ariskofexplosionspertains.

These instructions must be strictly observed.

Non-observance can result in injury or substan-

tial material damage.

2.3. Electrical work

DANGER due to electrical voltage!

Improper procedures during electrical work

may result in fatal injuries caused by electrical

voltage! Such work may only be carried out by

aqualied electrician.

BEWARE of moisture!

Ingress of moisture will result in damage to

the switchgear. During installation and oper-

ation, pay attention to the permissible air hu-

midity and ensure the switchgear is installed

so it is overow-proof.

Our switchgears are operated with alternat-

ingorthree-phasecurrent.Thegoverning

national directives, standards and regulations

(e.g.VDE0100)aswellastherequirementsofthe

local energy supply company must be observed.

The person operating the switchgear must know

where it is supplied with power and how to cut off

thesupply.Aresidual-currentdevice(RCD)must

be provided by the customer.

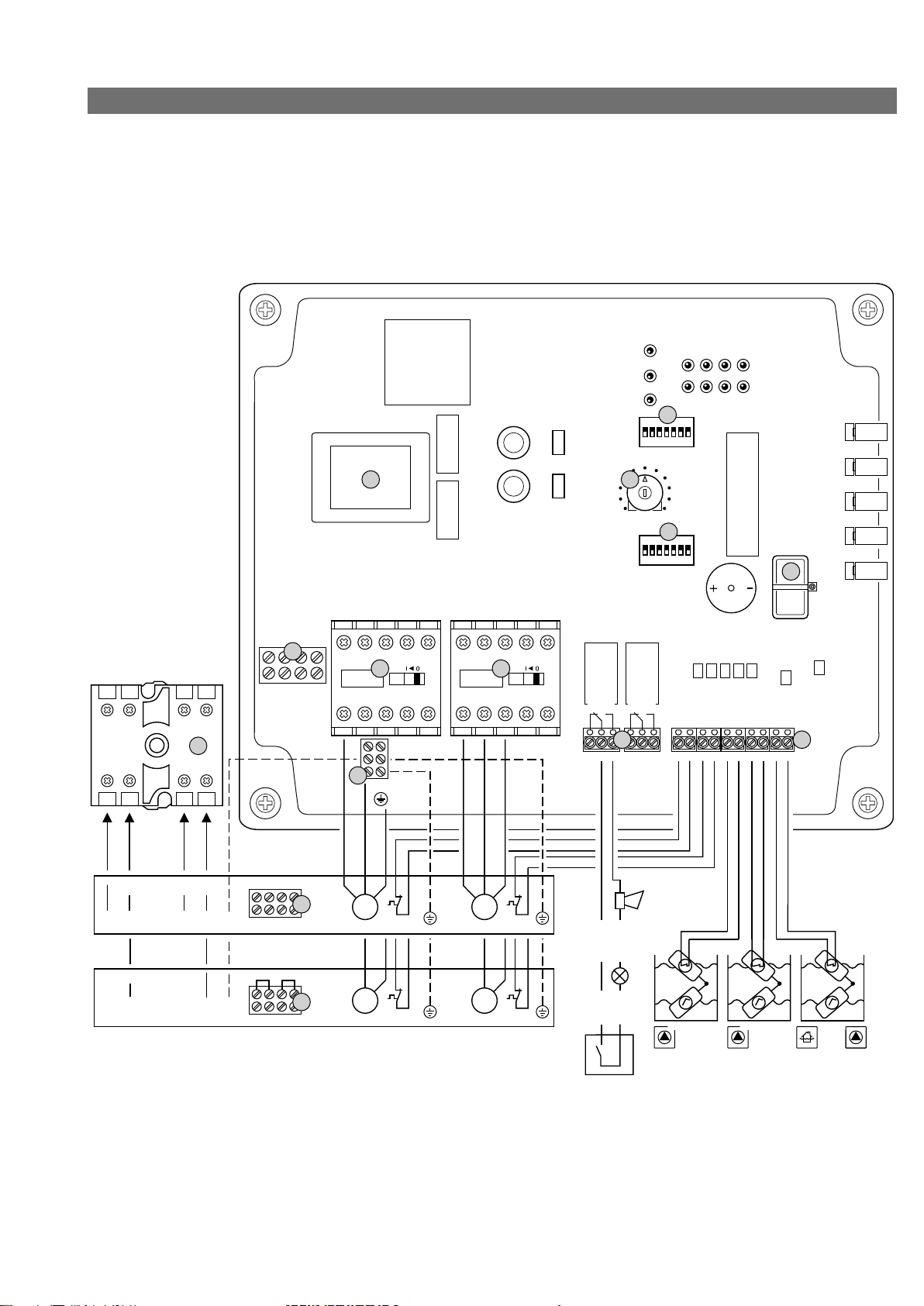

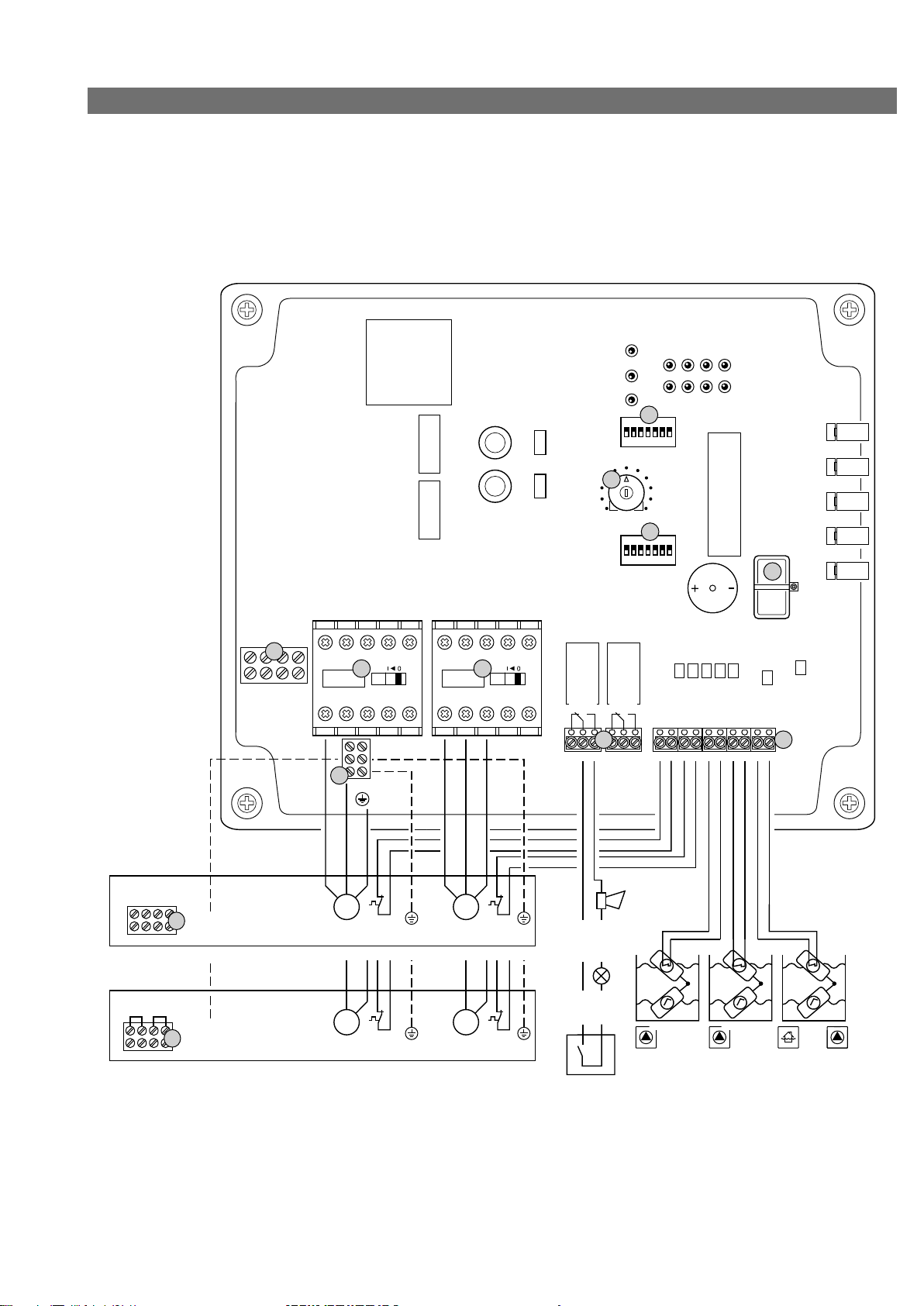

Thesectionentitled"Electricalconnection"

must be observed when connecting the product.

Thetechnicalspecicationsmustbeobserved

strictly.Theswitchgearmustalwaysbegrounded.

Todothis,connecttheprotectiveearthconduc-

tor at the earth terminal indicated (;).Thecross

section of the cable for the protective earth con-

ductor must correspond to the local regulations.

If the switchgear has been switched off by

aprotective device, it must not be switched on

again until the fault has been corrected.

Use of electronic devices such as soft starters

or frequency converters is not possible with this

switchgear. Pumps must be connected directly.

2.4. Conduct during operation

When operating the switchgear, always follow the

locally applicable laws and regulations for work

safety, accident prevention and handling elec-

tricalproducts.Tohelptoensuresafeworking

practice, the responsibilities of employees should

beclearlysetoutbytheoperator.Allpersonnel

are responsible for ensuring that regulations are

observed.