en

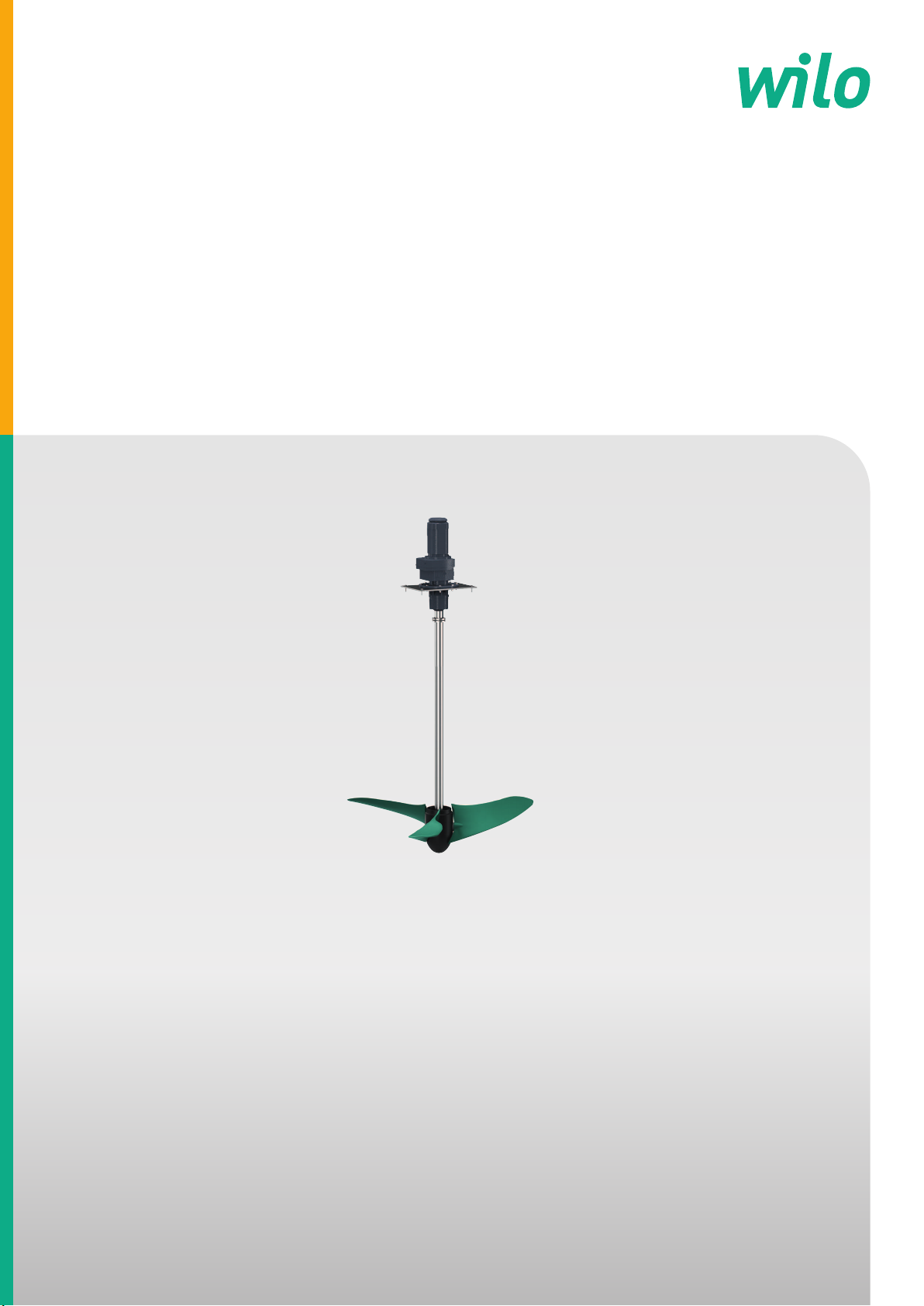

Installation and operating instructions Wilo-Vardo WEEDLESS-F 3

Table of contents

1 General information ................................................................................................................................................................. 5

1.1 About these instructions ..................................................................................................................................................................................5

1.2 Copyright ............................................................................................................................................................................................................5

1.3 Subject to change..............................................................................................................................................................................................5

1.4 Warranty..............................................................................................................................................................................................................5

2 Safety......................................................................................................................................................................................... 5

2.1 Identification of safety instructions................................................................................................................................................................5

2.2 Personnel qualifications....................................................................................................................................................................................7

2.3 Electrical work ....................................................................................................................................................................................................7

2.4 Monitoring devices ............................................................................................................................................................................................7

2.5 Drive unit: Gear motor in mixer version ..........................................................................................................................................................8

2.6 Use in fluids hazardous to health ....................................................................................................................................................................8

2.7 Transport.............................................................................................................................................................................................................8

2.8 Installing/dismantling........................................................................................................................................................................................8

2.9 During operation ................................................................................................................................................................................................9

2.10 Maintenance tasks.............................................................................................................................................................................................9

2.11 Operating fluid ...................................................................................................................................................................................................9

2.12 Operator responsibilities...................................................................................................................................................................................9

3 Application/use....................................................................................................................................................................... 10

3.1 Intended use.................................................................................................................................................................................................... 10

3.2 Improper use.................................................................................................................................................................................................... 10

4 Product description................................................................................................................................................................ 10

4.1 Design............................................................................................................................................................................................................... 10

4.2 Operation in an explosive atmosphere ........................................................................................................................................................ 11

4.3 Type key........................................................................................................................................................................................................... 12

4.4 Rating plate...................................................................................................................................................................................................... 13

4.5 Scope of delivery............................................................................................................................................................................................. 13

5 Transportation and storage................................................................................................................................................... 13

5.1 Delivery............................................................................................................................................................................................................. 13

5.2 Transport.......................................................................................................................................................................................................... 14

5.3 Storage ............................................................................................................................................................................................................. 15

6 Installation and electrical connection .................................................................................................................................. 16

6.1 Personnel qualifications................................................................................................................................................................................. 16

6.2 Operator responsibilities................................................................................................................................................................................ 16

6.3 Installation ....................................................................................................................................................................................................... 16

6.4 Electrical connection...................................................................................................................................................................................... 21

6.5 Recommended monitoring devices.............................................................................................................................................................. 22

7 Commissioning........................................................................................................................................................................ 22

7.1 Personnel qualifications................................................................................................................................................................................. 22

7.2 Operator responsibilities................................................................................................................................................................................ 22

7.3 Operation in an explosive atmosphere ........................................................................................................................................................ 22

7.4 Direction of rotation....................................................................................................................................................................................... 23

7.5 Before activating............................................................................................................................................................................................. 23

7.6 Switch on and off............................................................................................................................................................................................ 24

7.7 During operation ............................................................................................................................................................................................. 24

8 Shut-down/dismantling......................................................................................................................................................... 25

8.1 Personnel qualifications................................................................................................................................................................................. 25

8.2 Operator responsibilities................................................................................................................................................................................ 25

8.3 Decommissioning............................................................................................................................................................................................ 25

8.4 Dismantling...................................................................................................................................................................................................... 25

8.5 Clean and disinfect ......................................................................................................................................................................................... 27

9 Maintenance and repair.......................................................................................................................................................... 28