Remove all adjustment wrenches or other wrenches before switching on the power tool.

wrench hanging on a rotating part of the power tool can cause injury.

Do not lean too far. Make sure you have a secure stance and keep your balance. This gives

you better control over the electrical device in the event of unexpected situations.

Wear appropriate clothing. Do not wear loose or loose clothing or jewellery. Keep your hair,

clothing, and gloves away from moving parts as they can get caught in them.

If devices for connecting dust extraction and extraction systems are provided, ensure that they

are connected and used correctly. The use of dust separation can reduce dust-related haz-

ards.

Use and care of electrical appliances

Do not use the electrical appliance with force. Use the correct power tool for your application.

The right power tool will do the job better and safer at the speed for which it was designed.

Do not use the electrical device if it cannot be switched on and off using the switch. ny power

tool that cannot be switched using the switch is dangerous and must be repaired by a special-

ist.

Disconnect the plug from the power source and/or the battery of the power tool before making

adjustments, changing accessories or storing power tools. Such preventive safety measures

reduce the risk of the power tool being started accidentally.

When not in use, store the device out of the reach of children. Do not allow the device to be

operated by persons who are not familiar with its use or these instructions. The device can be

dangerous in the hands of inexperienced users.

Maintain the device regularly. Check for incorrect assembly or blockage of moving parts, for

defects, damage, and for any other circumstance that could limit the operation of the device. If

the device is damaged, have it repaired before further use. Many accidents are due to poor

maintenance.

Keep cutting tools sharp and clean. Correctly maintained cutting tools with sharp cutting edges

are less prone to sticking and are also easier to move.

Use the power tool, accessories, tools etc. in accordance with these instructions, taking into

account the working conditions and the work to be performed. Using the power tool for work

other than that for which it was intended can lead to dangerous situations.

Machine-related instructions

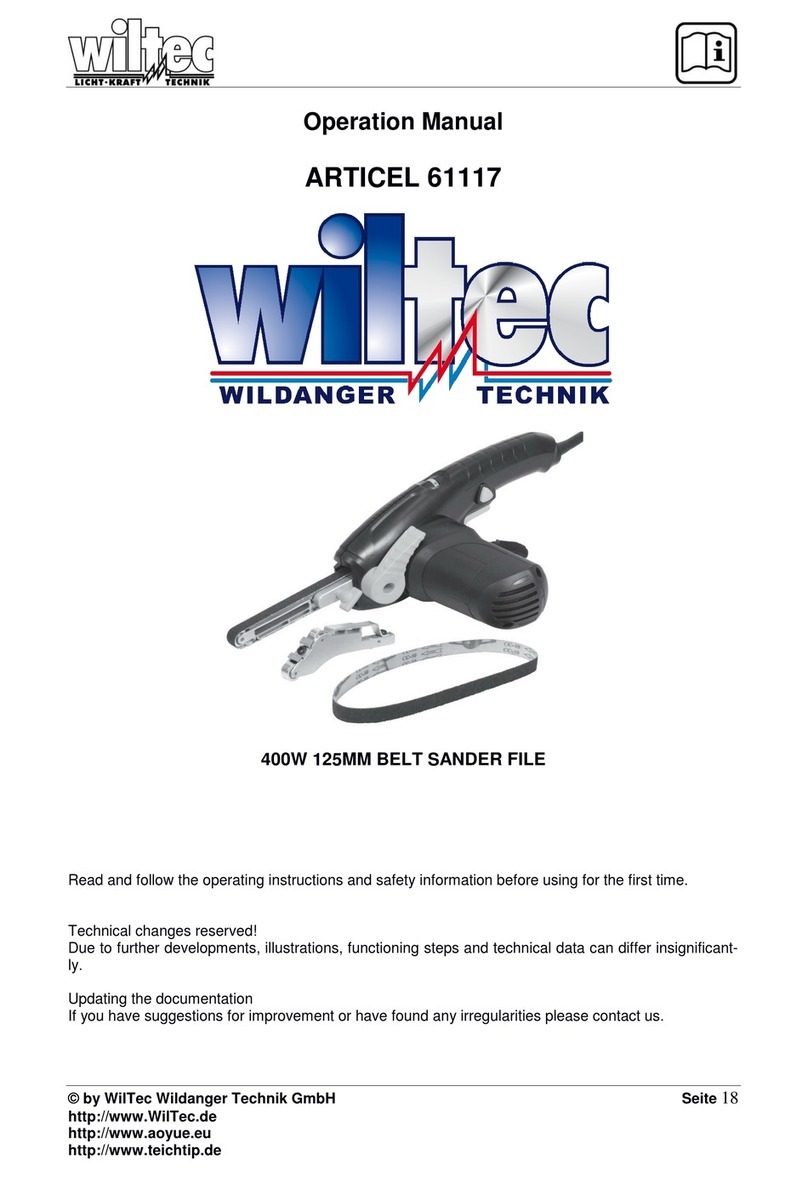

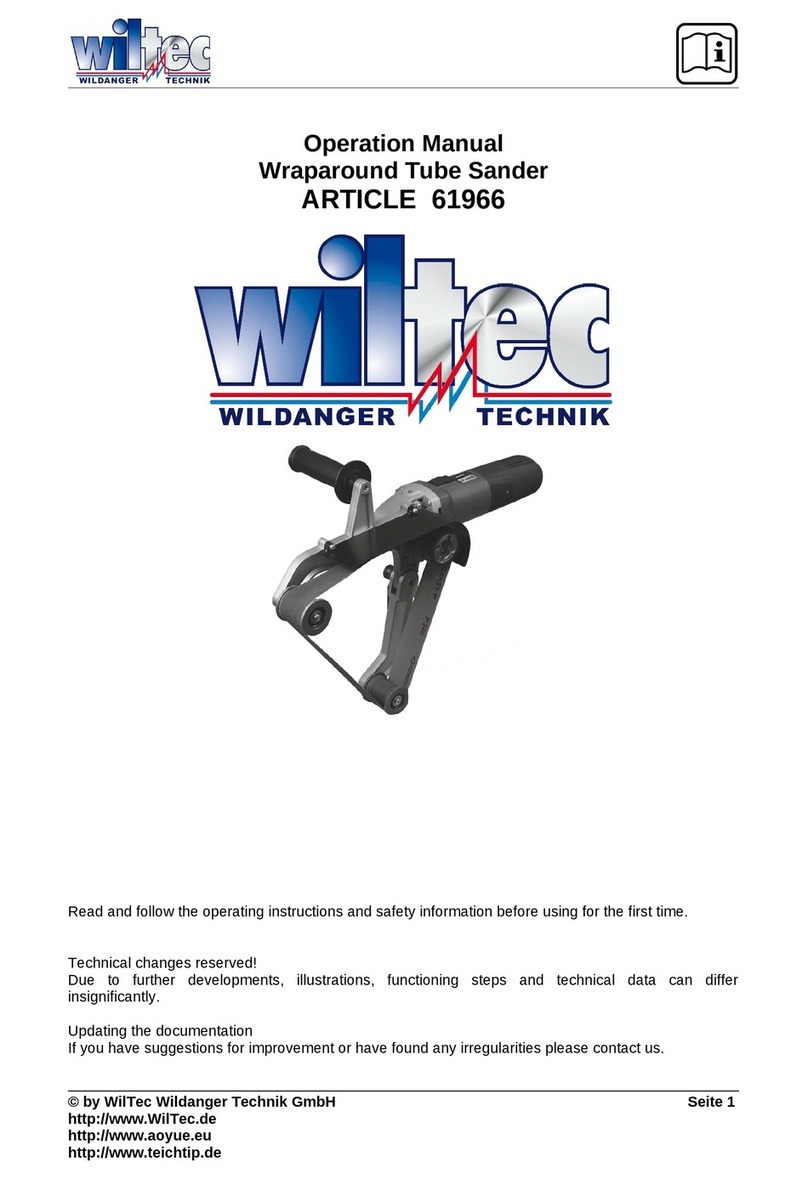

This machine is designed for grinding. Please read all safety notices, instructions, illustrations

and descriptions supplied with the machine. Failure to follow the instructions below could res-

ult in electric shock, fire, and/or serious injury.

Do not use this machine for jobs such as scrubbing, brushing, polishing, or disc grinding. Per-

forming tasks for which the machine was not designed can lead to danger and injuries.

Never use accessories that are not specifically designed and intended for this machine. Safe

operation is not automatically guaranteed just because an accessory can be attached to your

machine.

The permissible speed of the accessories must be at least as high as the maximum speed

specified on the machine. ccessories that rotate faster than the permitted speed can break.

The outside diameter and thickness of the accessories must be within the specified size range

of the machine. ccessories with incorrect dimensions cannot be adequately protected or con-

trolled.

The bore diameter of washers, flanges, retaining plates and all other accessories must fit ex-

actly on the machine spindle. ccessories with an unsuitable diameter run out-of-round, vi-

brate heavily and lead to loss of control.

Do not use damaged accessories. Before each use, check the accessories, e.Jg. abrasive

pads, nicks or kinks and backing plates for cracks and excessive wear. Every time the ma-

chine has been dropped, check whether the machine and the accessories are damaged and,

if necessary, mount undamaged accessories. fter checking and installing the accessories,

ensure that everyone is out of the rotating range of the tool and allow the machine to run at

maximum speed for one minute. Damaged accessories usually break through completely dur-

ing this test run.

© by WilTec Wildanger Technik GmbH Item 62531 Page 7

http://www.WilTec.de

http://www.aoyue.eu 01 2021-1

http://www.teichtip.de