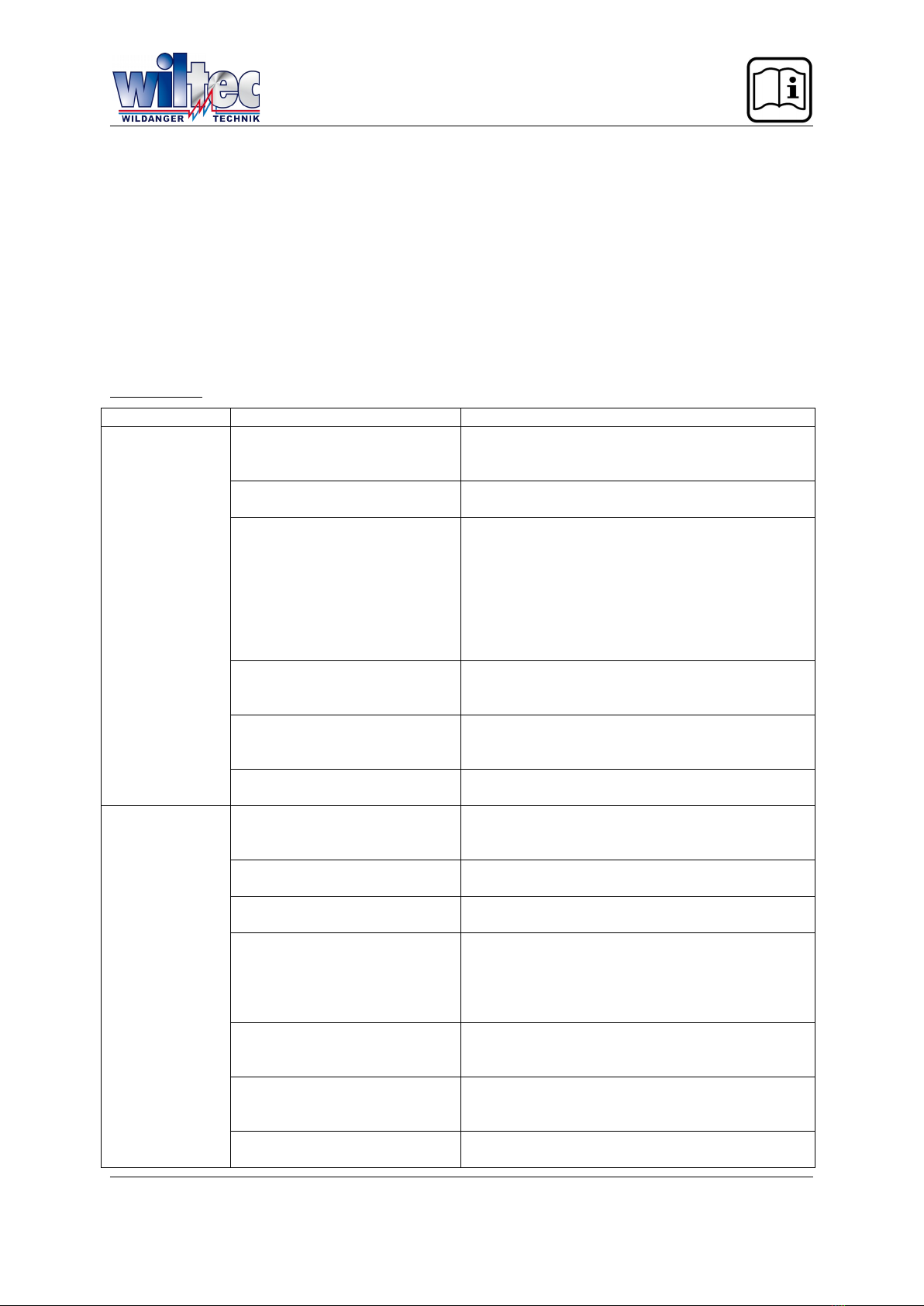

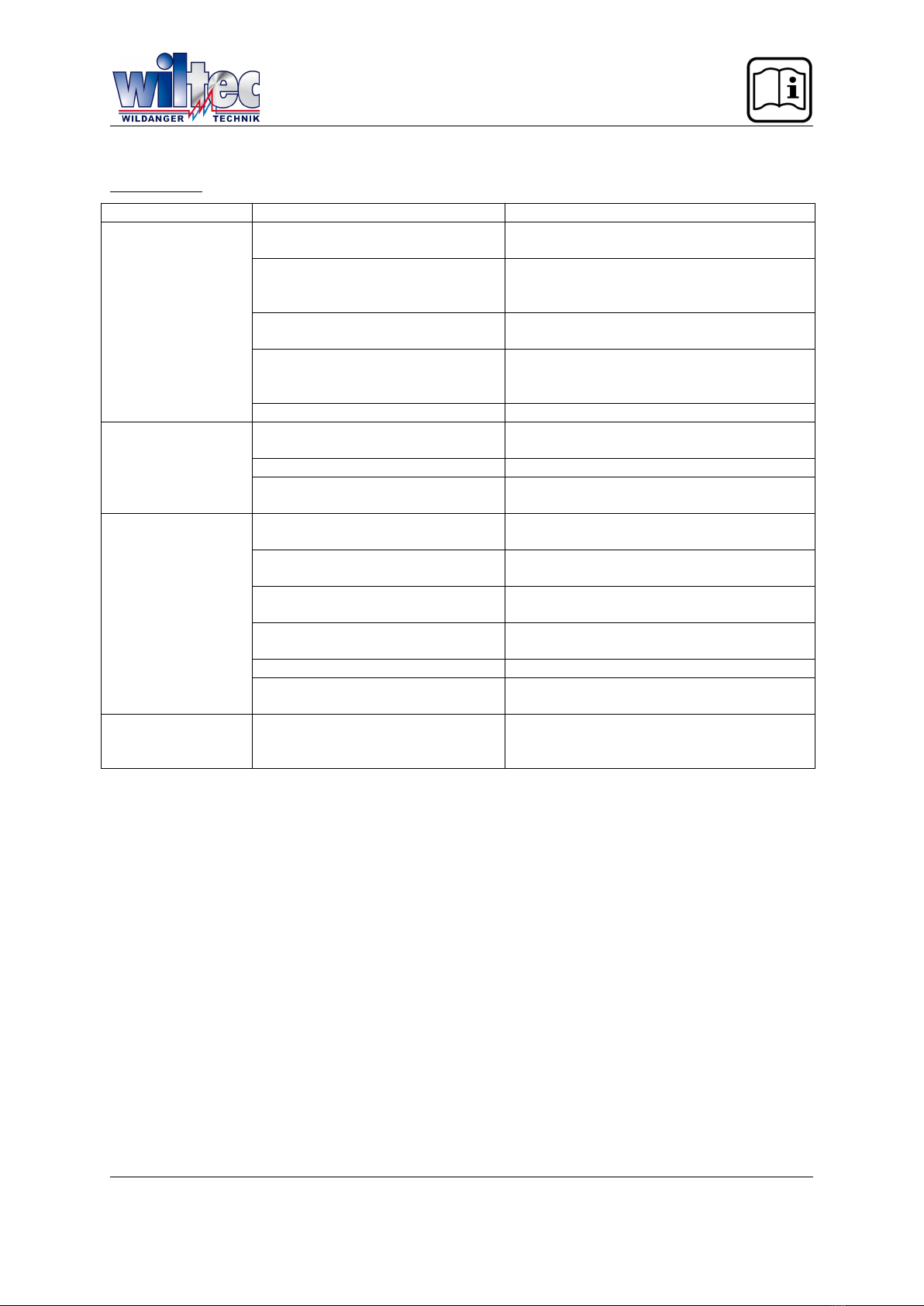

FAULT AND REMEDIAL MEASURES (61540)

In most cases, you will be able to troubleshoot problems easily by yourself. Before you contact us,

please refer to following table for technical support. This will help you save a lot of work possible ex-

penses.

If you are unable to remove the faults, please contact the local suppliers immediately. Please remem-

ber that the repairing of laypeople will invalidate your warranty and claims for compensation and give

rise to the extra costs.

Model 61540

Error Reasons Response measures

The pump fails

to make opera-

tion or the pump

stops suddenly

during opera-

tion.

1. Power supply interruption/

access failure of external

power supply

Check the fuse device and electrical connection

and switch on the external power supply.

2. The power line or plug is de-

fective

Ask the professional electricians to make inspec-

tion.

3. The mechanical seal is

sucked

Considering that the mechanical seal will suffer

from resistance when it is idle for a long period,

please switch off the pump and pull out the

power plug.

Please cool the pump and apply the slot-type

screwdriver to rotate the tail of shaft. When the

shaft becomes flexible, please power on the

pump.

4. Due to the pressure in the

pipeline the pressure switch

should shut off the circuit.

Please open the faucet. At this moment the pres-

sure switch will power on automatically after de-

pressurization.

5. The installation height of

faucet has exceeded the pres-

sure value of pressure switch.

When necessary, please adjust the pressure

setup value of the pressure switch.

6. Other faults Please ask the maintenance department to make

inspection.

Insufficient flow

rate/flow rate

absence (or

self-absorption

failure)

1. The dirty water or grainy

wastewater will reduce the

suction capacity of the pump.

Please clean up the filter screen and replace the

damaged spare parts (such as the worn impeller

and so on.).

2. Hose/pipeline/filter screen

plugging.

Dredge the pipeline/clean up the filter screen.

3. The hose/pipeline system is

damaged.

Replace the pipeline.

4. The water inlet is exces-

sively soft. As a result the wa-

ter inlet fails to draw water due

to the suction flattening during

the pump operation.

Please replace the threaded anti-vacuum hose

or pressure-proof hard tube.

5. Due to the air in the pump

head, the pump fails to be

completely filled with water

Please fill the pump head up with water.

6. Please immerse the water

inlet in water for 10 cm at

least.

Please check whether the water source is

enough. Then immerse the water inlet in water

for more than 10 cm.

7. The joint of suction pipeline

is untightened.

Please replace the joint sealing element and

completely seal the joint.

© by WilTec Wildanger Tec nik GmbH Seite 17

ttp://www.WilTec.de

ttp://www.aoyue.eu

ttp://www.teic tip.de