Wintex Agro, Vilhelmsborgvej 8C, DK-7700 Thisted

+45 97990800, contact@wintexagro.com, www.wintexagro.com

1. STARTING THE WINTEX 2000

Start the vehicle, and deactivate the emergency stop. The red button must be up.

Activate the foot switch and the brake on the handle bar, and shortly push the button at your right

hand. Foot switch and brake lever must be activated during the entire process. If one of these

switches is released, the process will stop.

If the soil sampler is delivered with a remote control, activate the dead-man’s vigilance system

instead of the foot switch.

Note: The emergency stop must always be activated at long stops, or the battery might be

discharged.

2. SELECTION OF PROGRAM

Program 1 takes a soil sample from 0-60 cm. The depth can be adjusted.

Program 2 takes soil samples from two different layers, from 0-30 cm and from 30-60 cm. The depth

can be adjusted.

The soil sampler is adjusted to standard rotation (= extra rotation “off”). It is possible to add an extra rotation

(= extra rotation “on”).

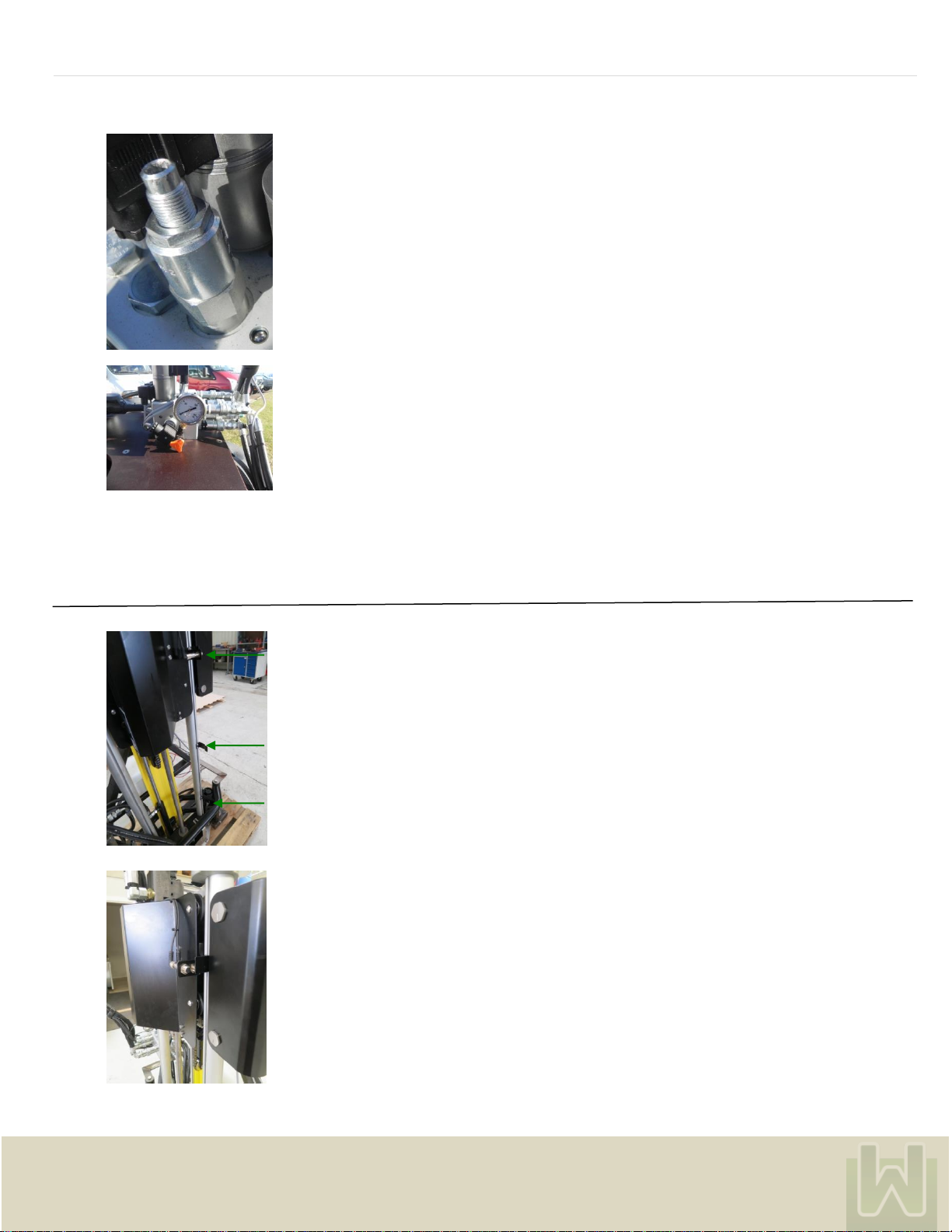

3. ADJUSTING THE DEPTH

The lower sensor plate defines the depth in program 1 and in program 2. Loosen the screws, and

move the sensor plate up or down to the desired depth.

The upper sensor plate defines where the soil sample in program 2 will be divided. The depth can be

adjusted from 0-30 cm. Loosen the screws, and move the sensor plate to the depth in which the soil

sample shall be divided.