3

www.wittur.com

Changes can be made without notice

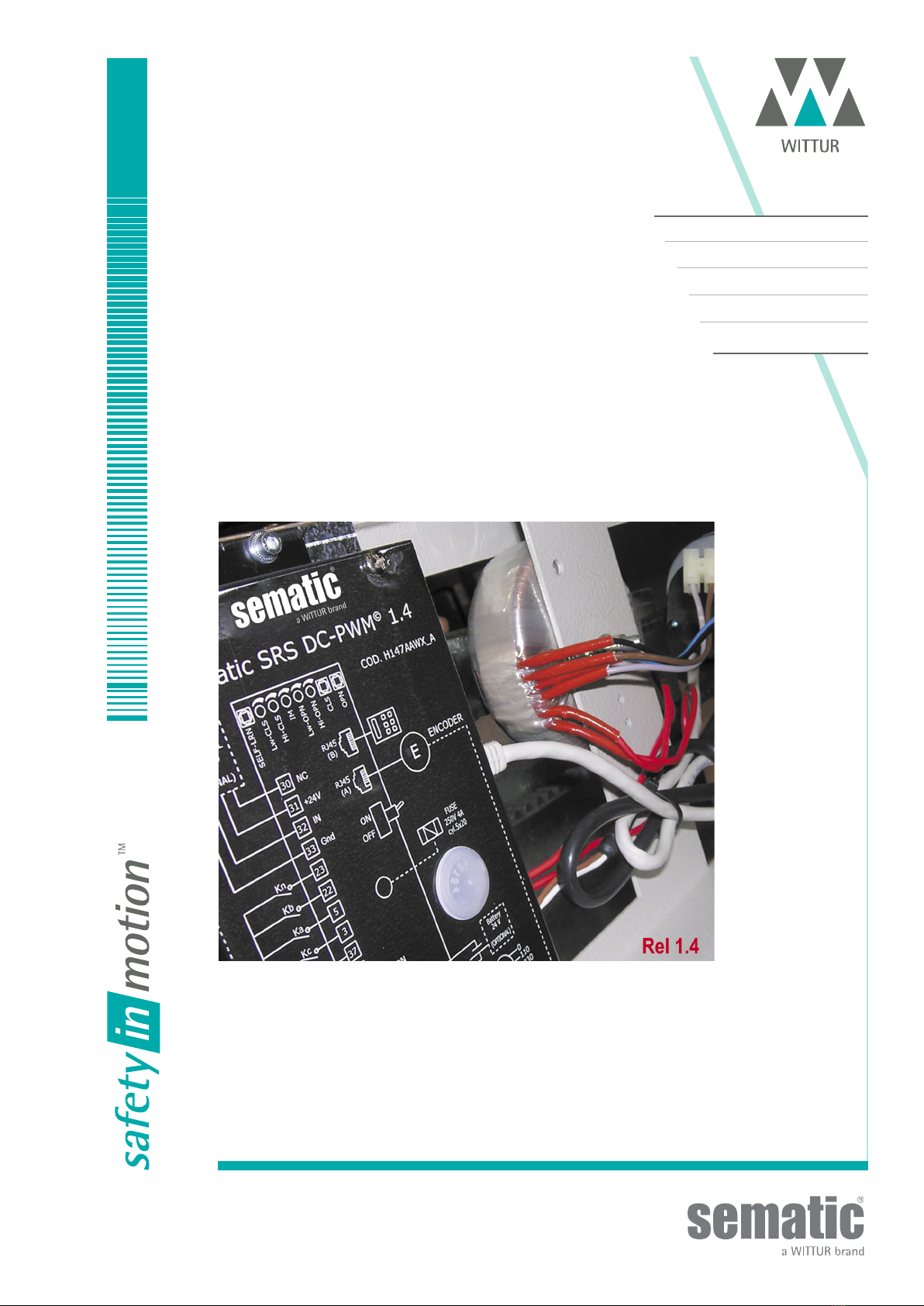

PM.2.004922.EN - 810-000-000 SRS DC-PWM©· Edition 22 July 2020

1 Preface ���������������������������������������������������������������������������������������������������������������������������������������������������� 7

2 What is the SRS DC-PWM©? ��������������������������������������������������������������������������������������������������������������������� 8

2.1 Speed profile (9) .......................................................................................................................................................................................9

3 General Features ������������������������������������������������������������������������������������������������������������������������������������ 10

3.1 Technical information ........................................................................................................................................................................10

3.2 Door Controller SRS DC-PWM© .......................................................................................................................................................10

4 Signals to/from the door controller����������������������������������������������������������������������������������������������������������� 11

4.1 Connections.............................................................................................................................................................................................11

4�1�1 Detector/Photocell/Barriers: Signal-Only Connection to the Door Controller (Direct Connection)������� 13

4�1�2 Detector/Photocell/Barriers: Complete Connection to the Door Controller��������������������������������������� 13

5 Instruction without handset��������������������������������������������������������������������������������������������������������������������� 14

5.1 Automatic Mode ....................................................................................................................................................................................14

5.2 Manual Mode..........................................................................................................................................................................................14

6 Functions ����������������������������������������������������������������������������������������������������������������������������������������������� 15

6.1 Reversing System Force ..................................................................................................................................................................... 15

6.2 Forced Closing (Nudging)................................................................................................................................................................... 15

6.3 Motor Rotation during closing.......................................................................................................................................................... 15

6.4 Skate type (Instruction with handset) ........................................................................................................................................... 15

6.5 Closing Rest type (Instruction with handset)..............................................................................................................................16

6�5�1 Motor on (default) ��������������������������������������������������������������������������������������������������������������������� 16

6.5.2 Motoro����������������������������������������������������������������������������������������������������������������������������������� 16

6�5�3 PM activation Delay (Default 300 sec�)����������������������������������������������������������������������������������������� 16

6�5�4 PM Opening space (Default 20 mm for STD skate, default 90 mm for EXP skate, default 120 mm for

EXP-B skate) ����������������������������������������������������������������������������������������������������������������������������� 16

6�5�5 PM position error (Default 5 mm)������������������������������������������������������������������������������������������������ 16

6.6 Motor (Instruction with handset) ....................................................................................................................................................16

6.7 Max current end CL (Instruction with handset) .........................................................................................................................16

6.8 LA Thresold (Instruction with handset) ........................................................................................................................................16

6.10 Alarms ......................................................................................................................................................................................................16

7 Trial operations before setting at work������������������������������������������������������������������������������������������������������ 18

7.1 Self-learning ..........................................................................................................................................................................................18

7.2 Self-learning cycle procedure (without using the handset) ..................................................................................................18

7.3 Speed profile regulation Trimmers (without handset) .............................................................................................................19

7.4 Reversing system force setting (without handset)....................................................................................................................19

8 Instruction with handset�������������������������������������������������������������������������������������������������������������������������� 20

8.1 Handset (optional) ............................................................................................................................................................................... 20

8.2 User Handset menus and submenus.............................................................................................................................................. 21

8.3 Self-learning cycle using the handset .......................................................................................................................................... 22

8.4 Speed Profile adjustments using the Handset............................................................................................................................ 22