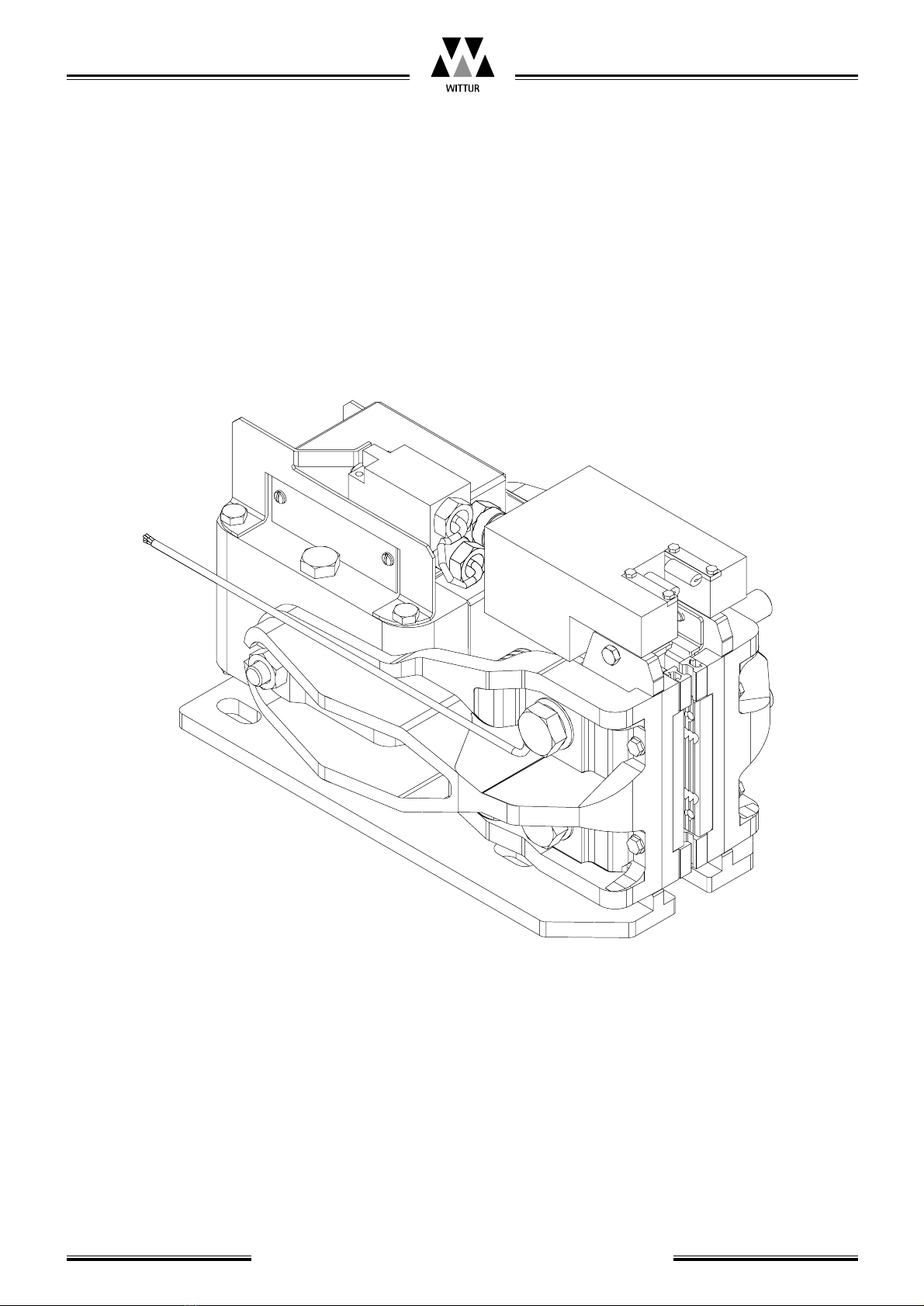

Braking System EBRA20

Operating instruction

Before starting installation work:

Only properly trained personnel may carry

out work, or be allowed access to the

installation site.

- Attach safety devices to guard against falling

(platform or harnesses)

- Cover any floor openings

- Secure installation tools or objects against

accidental falling

- Lift shaft openings should be cordoned off

and suitable warning signs should be erected

when working in shaft openings

- Work involving electrical equipment should

only be carried out by an electrical engineer or

qualified personnel.

1.4 Preparation

Before beginning installation work it is in your

own interest to ascertain the constructional and

spatial conditions. Where (workshop or on site)

and when which installation operations can or

must be carried out. It is recommended therefore,

taking into account all the given circumstances, to

plan the various operational sequences in advance,

rather than carrying them out prematurely and in

an unconsidered manner.

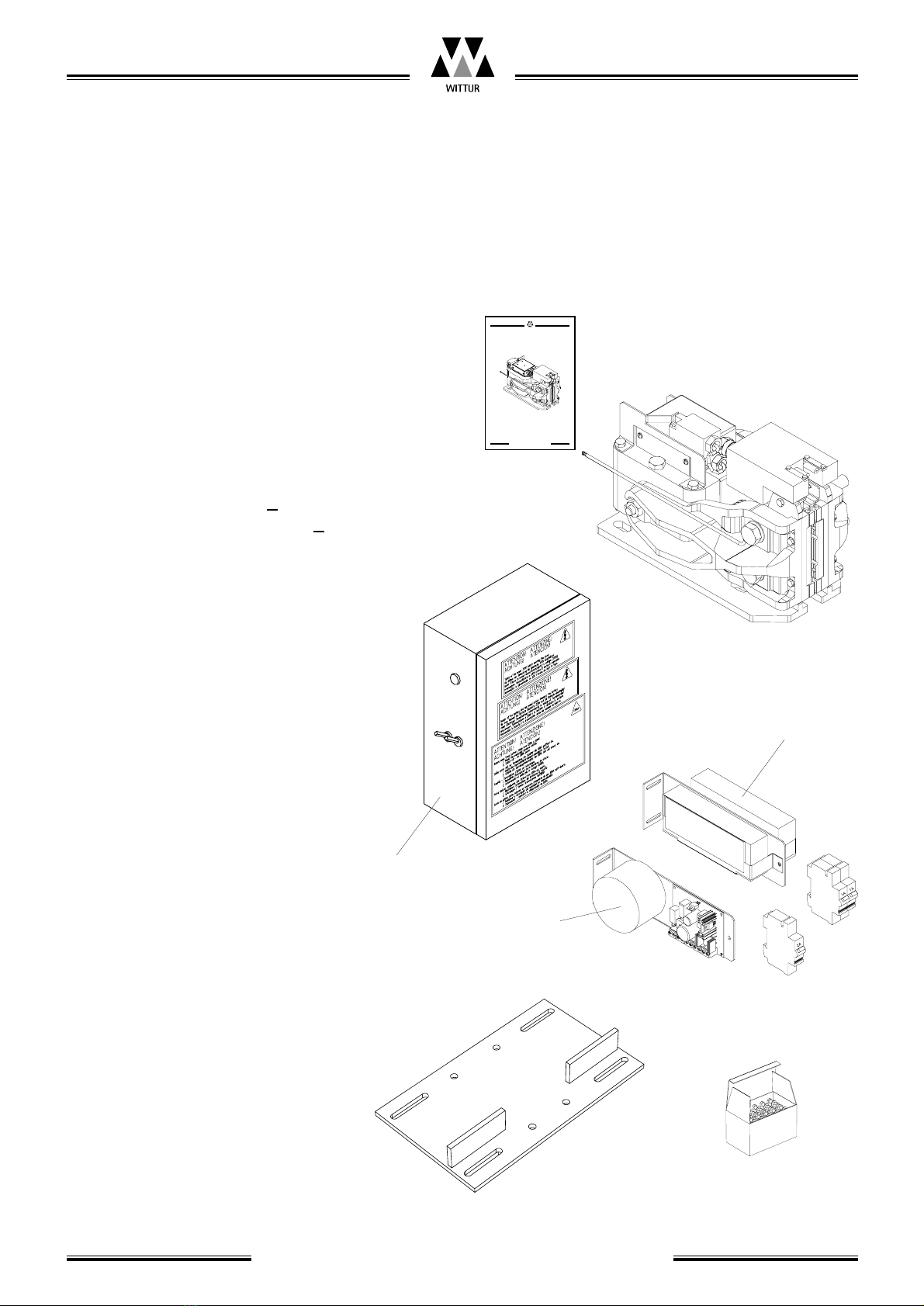

On receipt of the delivery, the goods or compo-

nents should be checked for correctness and com-

pleteness with the order sheet.

The following should be checked also:

- that the factory and order number correspond

- that the details on the name plate correspond

to those on the order

- the elevator speed

- the width and type of guide rail used

- the nominal load (Q)

1.5 Advice for when working on

safety components

The Brake system EBRA20 is classified as safety

components. It is most important that the stan-

dards and guidelines described in this section be

complied with as well as those given in the rest of

this operating manual.

These instructions, and especially the sec-

tion on safety precautions, should be read

and fully understood before work begins.

Safety devices require special attention. It is com-

pulsory that they function perfectly to ensure

danger free installation operation.

Safety devices that can only be adjusted after

installation should be done so immediately after

installation.

Operation of safety devices installed ex-works

must be tested immediately.

If it is necessary to disassemble a safety device

during servicing or repair, they should be reassem-

bled and comply with the required tests, as soon as

the work has been carried out.

Blatt/

sheet

D7AJMGB.004

Datum/

date

23.05.2002

Stand/

version

23.05.2002

Geprüft/

approved

WAT/MZE

THE LMC LIFTCOMPONENTS MANUFACTURING AND COMMERCE COMPANY

Änderungen vorbehalten! Subject to change without notice!