Blatt/sheet D550MGB.002

Datum/date 14.05.2001

Stand/version 14.05.2001

Geprüft/approved BRA/AD

Änderungen vorbehalten! Subject to change without notice!

THE LMC LIFTCOMPONENTS MANUFACTURING AND COMMERCE COMPANY

Hydraulic contact buffer

Operating instructions

1.1 Description and function

The hydraulic contact buffer type WHB is an

energy dissipation type buffer according to EN

81-1/2 and therefore can be universally used for

all applications in the construction of elevators.

The design type approval permits the use in pas-

senger and freight elevators both under the car

and under the counterweight.

Functional description (see fig. sheet 3)

In the case of a buffer stroke the piston rod (2) is

forced into the cylinder tube (1) and the hydrau-

lic fluid (3) in the tube is displaced and forced to

the outside through small throttling ports (4) in

the tube wall. The fluid accumulates within the

jacket tube (5).

At the same time the gas volume (6) above the

hydraulic medium is further compressed. The sea-

ling system (7) maintains a reliable seal between

the hard chromium-plated piston rod and the

atmosphere.

After the buffer stroke and return to hydraulic

balance the compressed gas volume forces the

displaced fluid back into the cylinder and extends

the piston rod.

The level of the hydraulic fluid at the gas interfa-

ce can be read at any time through the sight

glass (9) without opening the unit.

An elastic impact plate (16) damps the impact

and reduces the noise.

The limit switch (13) monitors the extended ready

position of the buffer. The limit switch is actuated

by pressure on the piston rod by the linear

slide (17) or the protection tube (10) respectively.

In the case of buffers equipped with a protection

tube (10), for maintenance work the screws (12)

on the buffer head (11) are removed. Subsequent-

ly, the protection tube can be lowered, which

simultaneously actuates the switch (13). The oil

filler screw (14) and the gas-filling valve (15) will

then be accessible.

In the normal operating state the protection tube

avoids damage and contamination of the piston

rod

1.2 Liability and guarantee

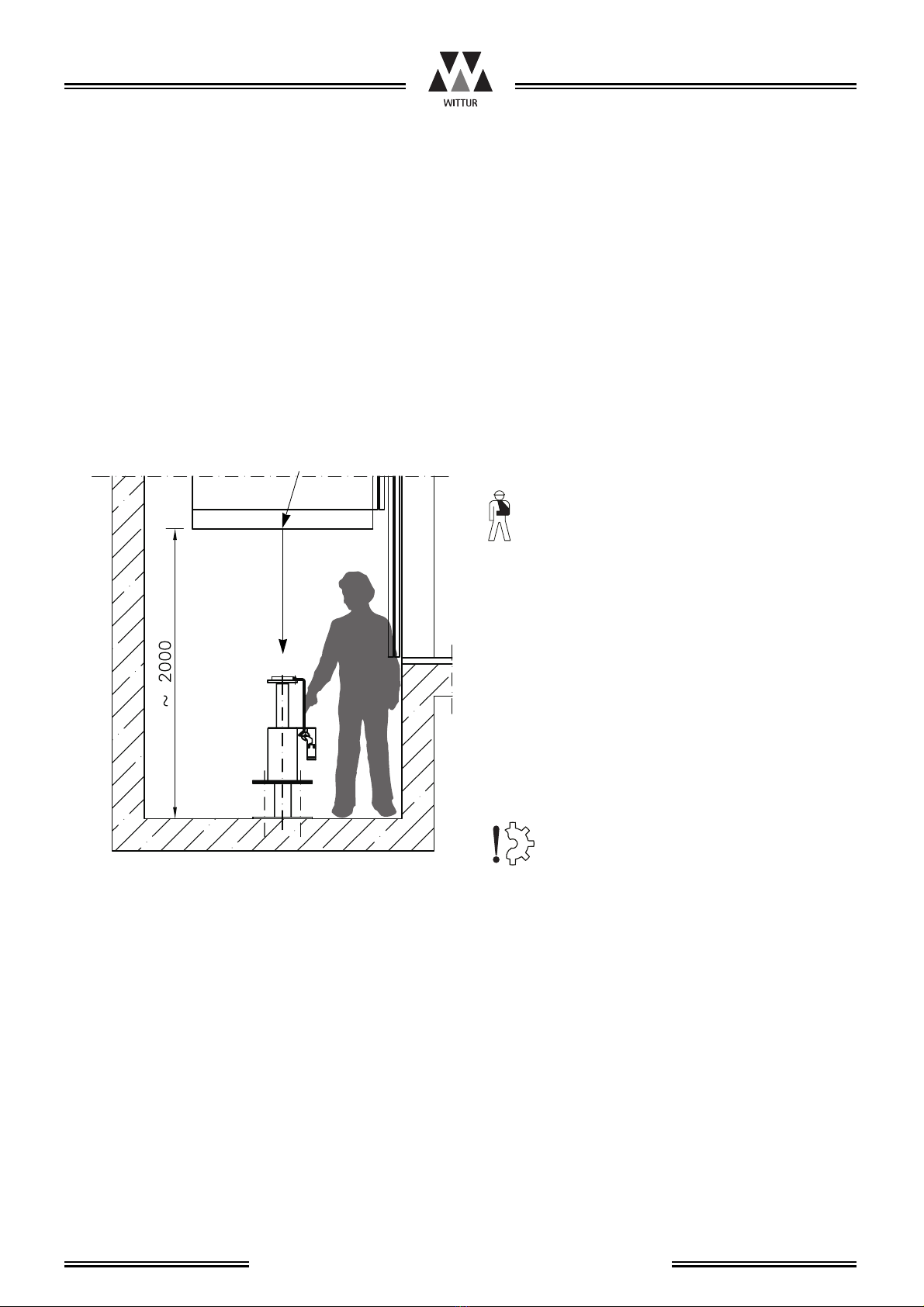

These operating instructions are intended for per-

sons who are familiar with the installation and

maintenance of lifts. Adequate knowledge of lift

construction is a prerequisite.

The WITTUR firm carries no responsibility for da-

mage caused by inpropriate or other actions un-

dertaken without adherance to these operating

instructions and thus compromising the qualities

of the product.

The warranty obligation of the WITTUR firm may

be inapplicable, if the component has been used

other than described in these instructions

Unless stated otherwise, the following are not

permissible due to technical safety reasons:

-installing the wrong buffer or one intended

for a different purpose according to these

instructions

-make changes of any kind to the hydraulic

contact buffers

furthermore

- carrying out faulty or improper maintenance,

maintenance or inspection checks and

- using unsuitable accessories, spare parts or

operating material which has neither been

released by the WITTUR Company nor consists

of original WITTUR spare parts.

1 General information prior to installation