http://www.facebook.com/OlympiaElectronics

http://twitter.com/olympiaelectro

http://www.linkedin.com/company/1967613?trk=tyah

http://www.youtube.com/channel/UCIINc4DGSYH_0loHJqwsgoQ

https://plus.google.com/105672704483774116420/posts

http://www.olympia-electronics.gr

GENERAL

BS-695 and BS-694 detectors are used to give

us a quick warning in case there is a natural gas

or LPG gas leak.

The installation must be done by a qualified

personnel. The instructions must be read first

before the installation.

Emergency actions

It is recommended that the following advice

should be given in the event of an alarm

sounding or the smell of gas even without an

alarm:

Keep calm, and carry out the following actions,

not necessarily in the order given:

- extinguish all naked flames, including

smoking material.

- turn off all gas appliances.

- do not switch on or off any electrical

equipment, including the gas detection

apparatus.

- turn off the gas supply at the gas main control

and/or ( with a LPG supply) the storage tank.

- open doors and windows to increase

ventilation;

- do not use a telephone in the building where

the presence of a gas is suspected.

If the alarm continues to operate, even after an

alarm resetting action where appropriate, and

the cause of the leak in not apparent and/or

cannot be corrected, vacate the premises and

IMMEDIATELY NOTIFY the gas supplier in

order that the installation may be tested and

made safe, and any necessary repair carried

out.

Placement

Depending on the monitored gas, the unit must

be placed 30cm from the ceiling (for methane,

natural gas) or 30cm from the floor (for propane,

butane, LPG). The horizontal distance should

not be more than 4 meters from the probable

gas leak point and the detectors must not be

placed in humid or drafty areas.

It is suggested that the detector is tested for

good operation every 6 months or if it is

changed position.

The unit must should not be sited:

- directly above cooking appliances.

- directly above sink.

- adjacent to extractor fans.

- in any outside location.

- where the environmental conditions are

outside the manufacturers operational

specification.

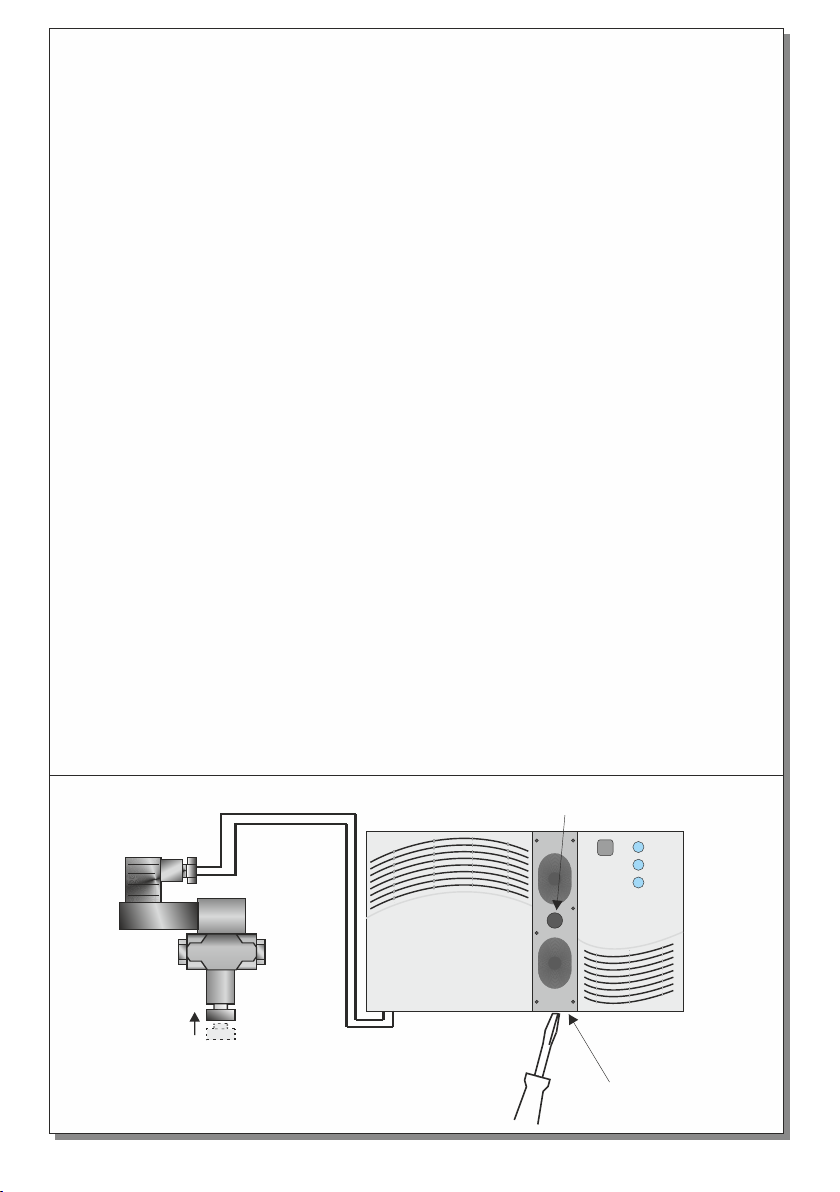

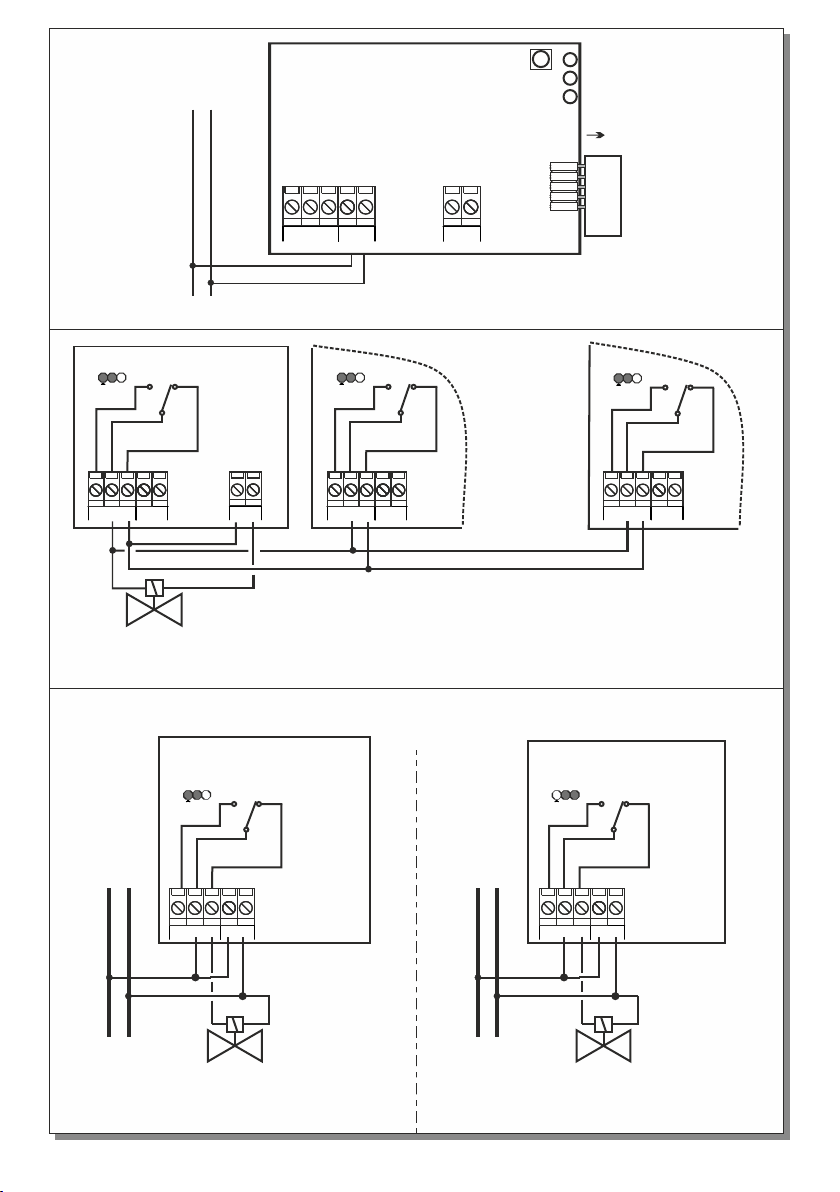

Installation

For the installation of the device first you must

remove the red plastic with a screwdriver as

shown in figure 1 and unscrew the screw in the

middle. Then with the help of figure 2 you can

connect the external devices.

Sensitivity

The BS-694 detectors are activated when the

220-240V AC/50-60Hz

Yes Yes

Relay (230V AC, 5Α)

Power LED , alarm LED , fault LED

IP40

5 years

EN 50194, EN 61000-3-2, EN 61000-3-3

o

0 to 60 C

Up to 95%

No No

5-15 % L.E.L. Propane 5-15 % L.E.L. Methane

145 x 85 x 45 mm

Bayblend FR3010

BS-694 BS-695

4VA

TECHNICAL CHARACTERISTICS

OPERATION TEMPERATURE RANGE

RELATIVE HUMIDITY

CONSTRUCTION MATERIALS

EXTERNAL DIMENSIONS

TYPICAL WEIGHT

GUARANTEE

OPERATION VOLTAGE

AVERAGE POWER CONSUMPTION

SENSITIVITY

OUTPUTS

ELECTRO VALVE OUTPUT

EXTERNAL BUZZER OUTPUT

SENSOR LIFETIME

INDICATIONS

DEGREES OF COVER PROTECTION

PRODUCED IN ACCORDANCE WITH

2 years

270gr.

BS-694 Autonomous LPG detector

BS-695 Autonomous natural gas-methane detector

Page 1 from 4

Thank you for your trust in our products.

Olympia Electronics - European manufacturer.

921695000_09_009