MD150E –pulses and velocity counter (02.06.2014)

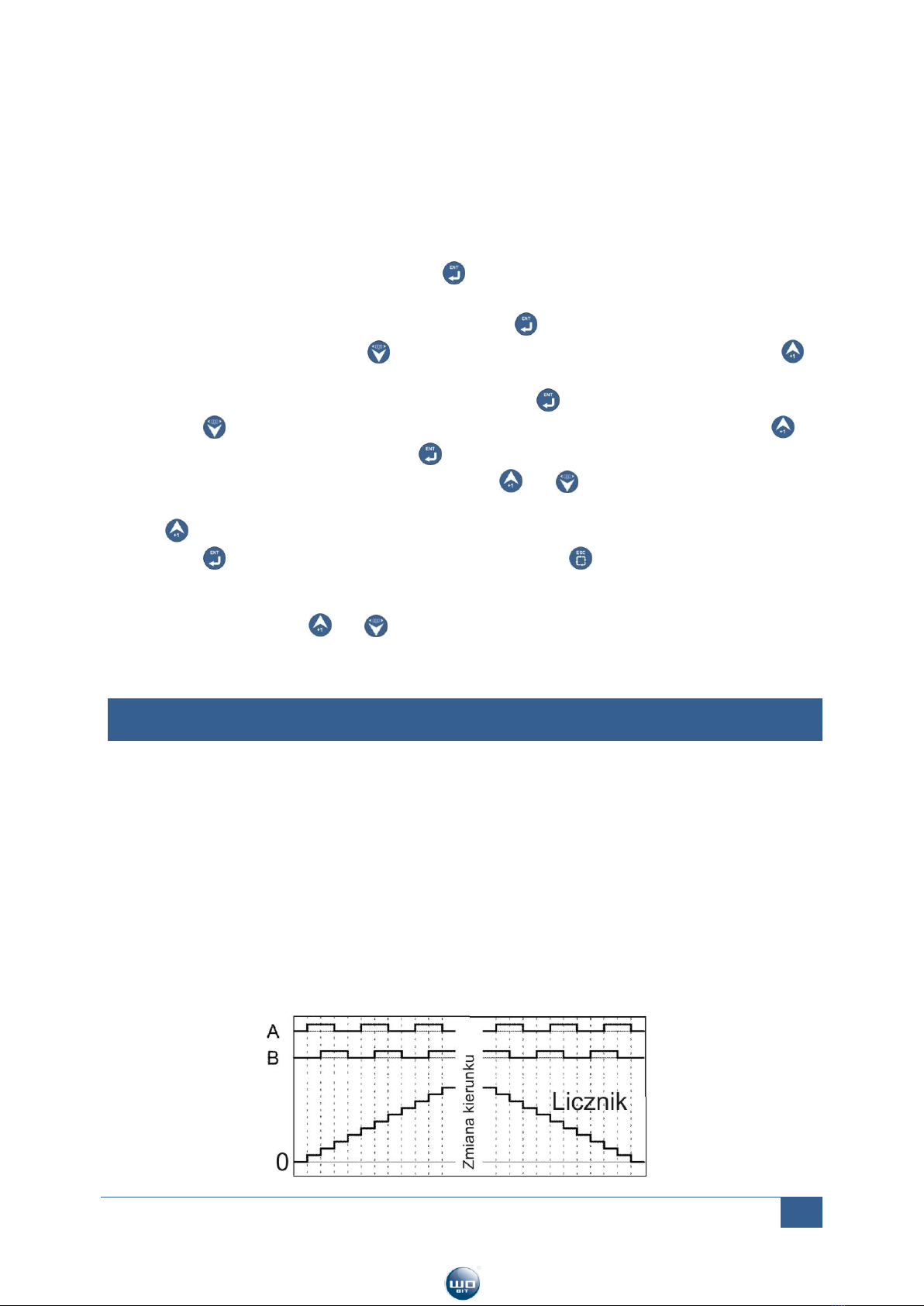

Encoders

Incremental encoders are designed for angle displacement measurement,

which means measurement of angle, number of rotation and angle

velocity. Using belt drive, cog wheel or friction wheel it is possible to

measure linear displacement.

Encoder allow to define position by counting pulses. It can also recognize

direction of movement due to phase shift of A and B channel (square wave signal).

Some encoders have C zero channel, which by each rotation indicates an absolute position. It can be

used for designation of zero position.

Linear magnetic encoders

Linear encoders are designed for direct measurement of linear

displacement. Incremental length measuring system consisting of read

head and magnetic tape. An example of sensor is GC-MK2 or GC-MK5

from WObit’s offer.

Proximity sensors, Area sensors

All sensors with output signal NPN or PNP can be connected directly to MD150E

counter to count number of this signals. For example this sensors can be used for

counting numbers of elements on a production line or for defining numbers of

rotation/ velocity of measuring wheel.

CLOCK/DIRECTION signals for controlling servomotors and stepper motor drivers

For controlling servomotors and stepper motor drivers often are used CLOCK/DIR signals. This signal

can be connected directly to MD150E counter, then it can be used for direct indication of motor

position/velocity.

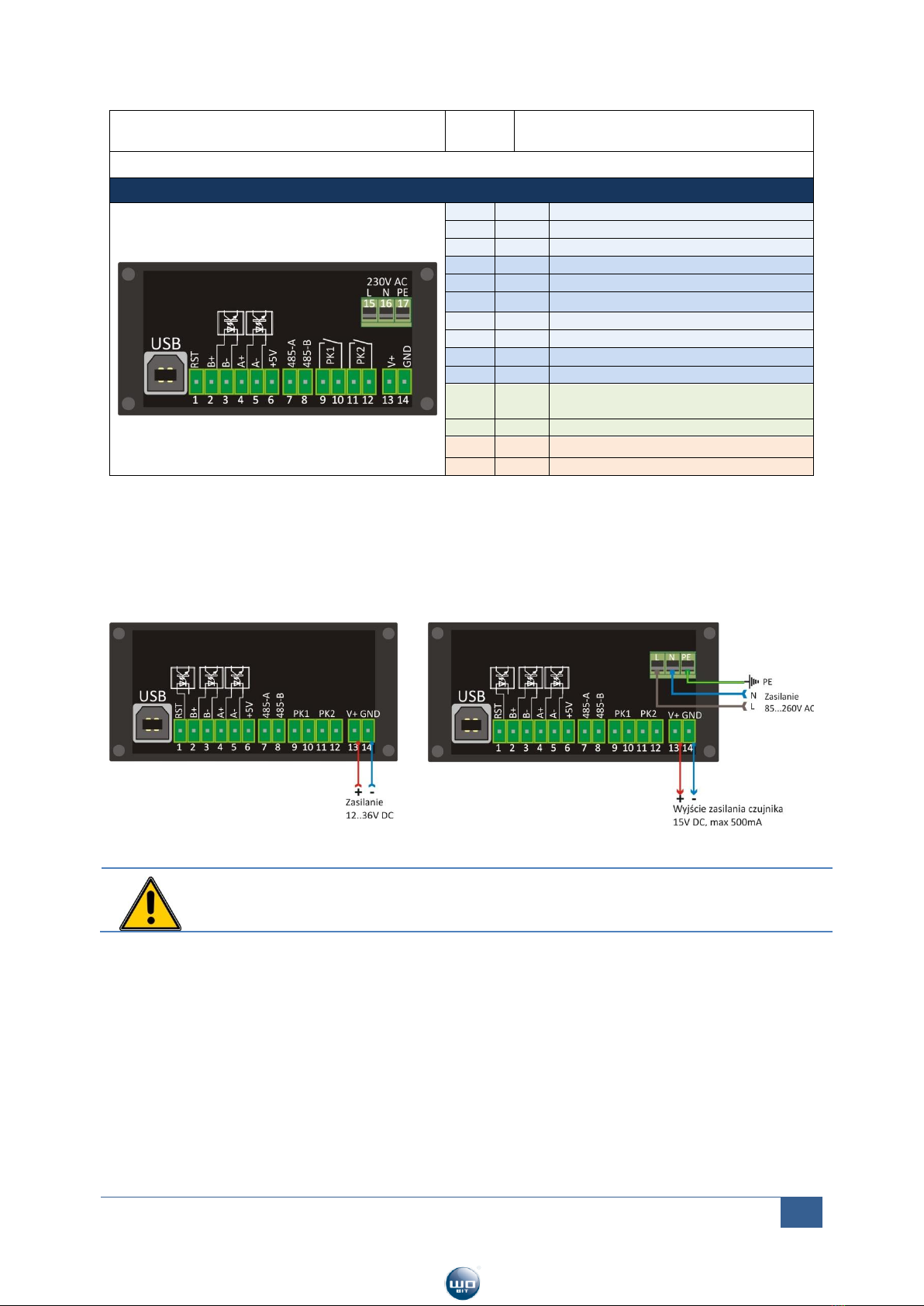

2.5 Input signals –way of connection

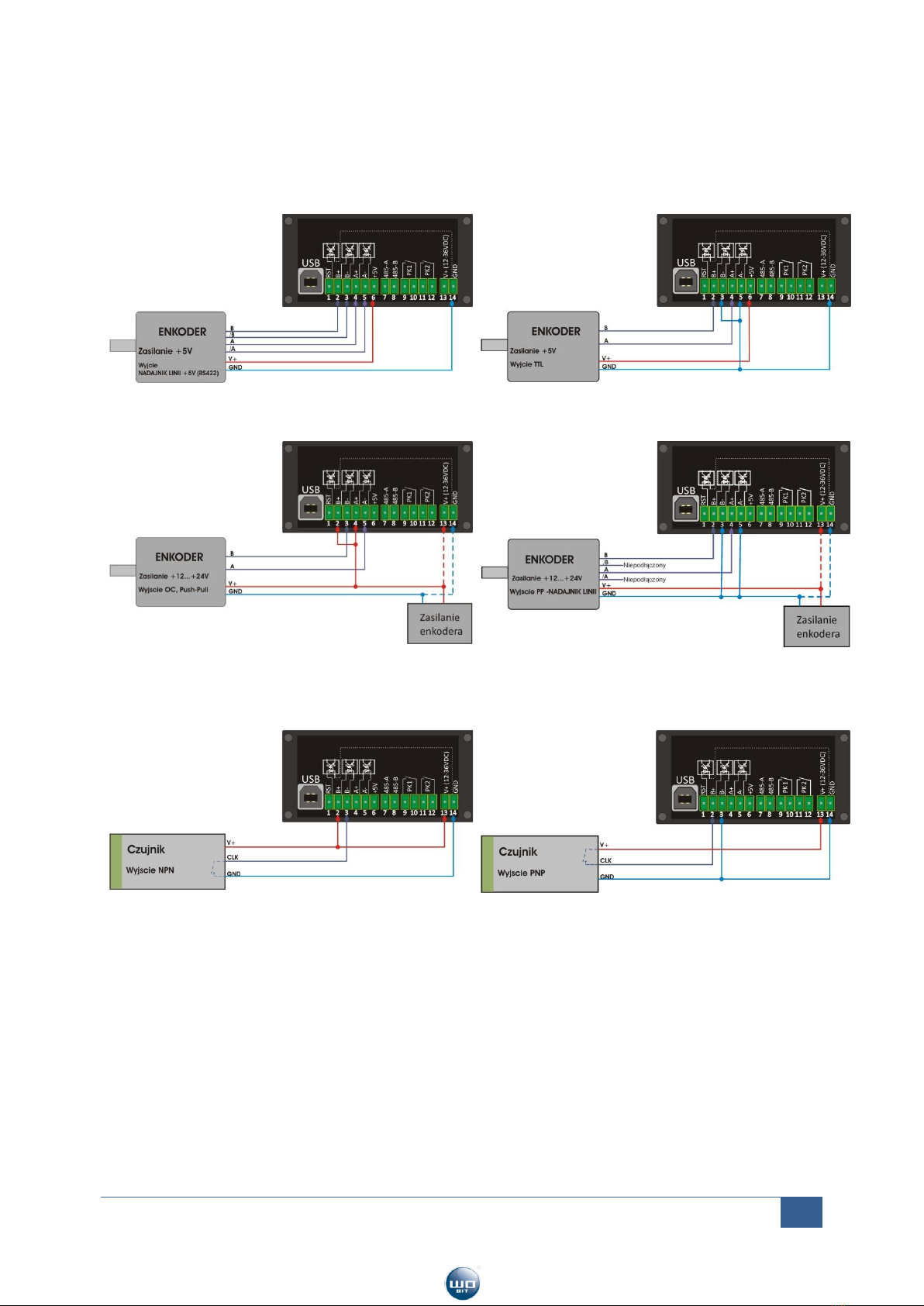

MD150E counts pulses from two opt insulated A and B input channels + zeroing signal (RST). This

signals can be given asymmetrically (input + or –connected to sensor’s ground) as well as

symmetrically (straight signal and negation + and - inputs simultaneously). Most of rotary and linear

encoders give asymmetrical signal (differential) due to greater transmission resistance for industrial

noise. Simple proximity sensors usually give straight signal (without negation).

Level of transducers input signal depend on electronic standard. The most popular is O.C. (voltage

supply +24 V, +12 or +5 V). This standard can’t be used for long distances with high signal frequency.

At distances up to 100 m and high rotational velocity of transducer usually is used Line Driver

standard (RS422). At this standard at transducer are available also A and B signal negations. Then

should be used proper cable with correct impedance (signal send in pairs, e.g. A+/A-).

MD150E has fully opt insulated differential counter inputs, on which can be given signals in range

5..24V (between „+” and „-”clamp). It can be integrated directly with most of sensors (supplied

from +5V as well as +24V).

Owing to input signal on opt-isolator is internally formed in square course with proper slope (for

correct pulse identification). As pulse generator can be used almost any element with slow increasing

pulse like optical sensor or proximity sensor. In case of electromechanical pulse sources, the