MAINTENANCE ALL MODELS CONTINUED

LUBRICATION

Lubrication

of

this

machine

is

easily

accomplished. Every eight hours of operation

add three to five drops of a good grade of 30

weight lubricating oil to Lubricator

(#1

below).

Do

not

over

lubricate.

NEVER

OIL

GRAPHITE CROSSHEAD GUIDES. (Heavy

duty steel guides require lubrication.) If oil

should get on Graphite Guides, they will

become gummy and stall the cutter. Should

this happen, clean the guides thoroughly by

flushing with Keep-M-Kleen solution. Guides

or Crosshead do not have to

be

removed from

machine

during

cleaning.

Add

oil

to

Crosshead wick after cleaning.

A few drops of oil should be placed on

moving parts and gears periodically, or after

they have been cleaned

in

solution. Excess oil

on grinder parts collects emery and will cause

faster wear and poor grinding. DO NOT OIL

THE ROLLERS

IN

THE FOOTPLATE.

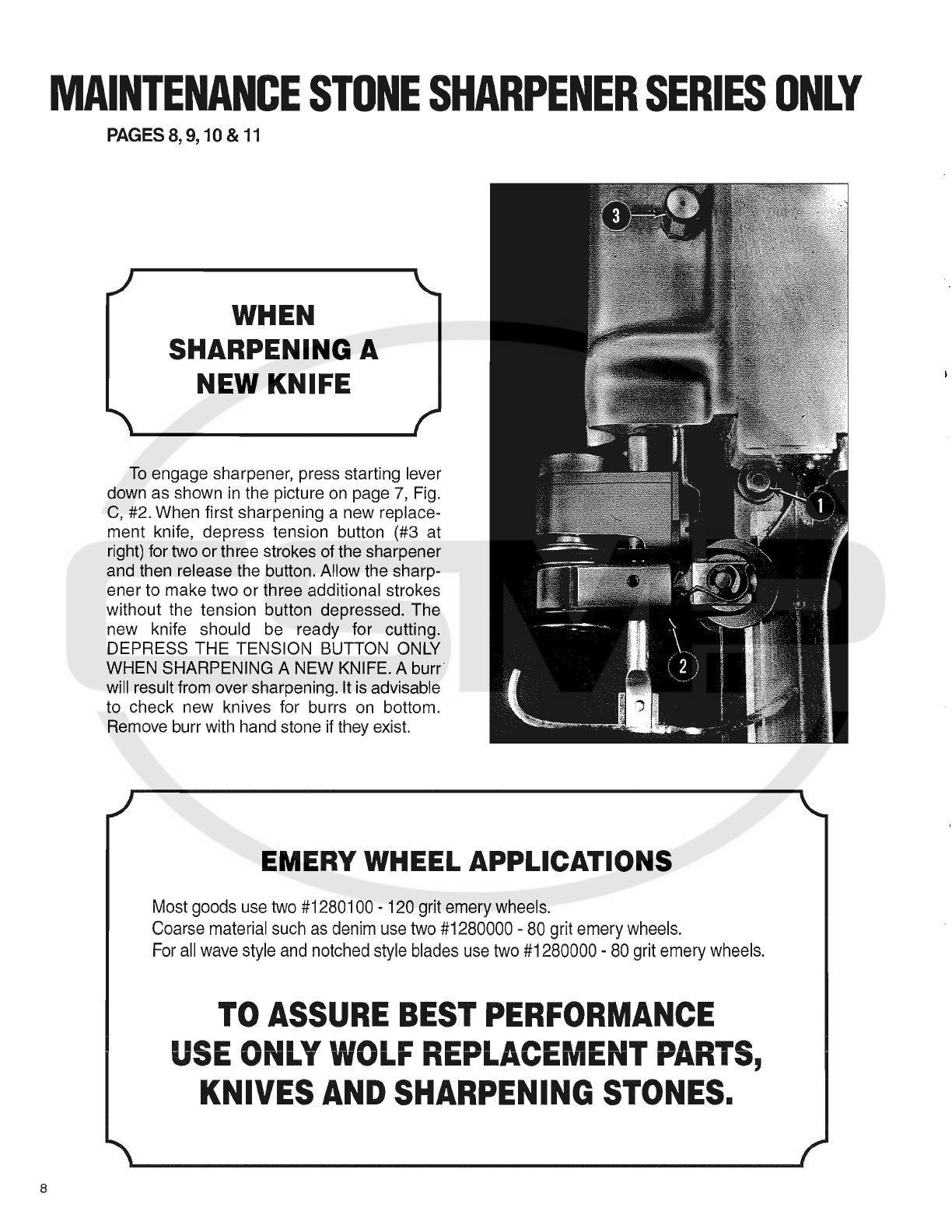

The center wick (#3 at left) should be soft

and come into contact with the Crosshead

Wick, when the Crosshead

is

at the top of the

stroke. Replace the wicks if they are worn

or

broken.

To

replace wick, remove the retaining

screw (#5 at left) while holding the lubricator

steady with your hand. The feeder tube may

now be pulled out.

To

take off entire oiler

assembly, use

an

open end wrench to remove

the oiler tube nut (#6 at left). This is a right

hand thread.

All ball bearings

in

this machine are

sealed, pre-lubricated bearings. If the crank

bearing needs to be greased

or

replaced,

remove Connecting Rod (see page

6,

Fig. A)

then remove the Bearing Locknut (#4 at left)

with

Pin

Wrench (#1091060).The bearing can

now be pulled from the Crank with the Crank

Pin

Puller (not illustrated). Use a good grade

of high speed bearing grease available from

the factory. Bearings should be replaced only

with the bearing knockers sold from Wolf. For

accessories, lubricants and tools, see

page 37.

5