WARNINGS:

•Hollis BC’s are intended for use by divers who have successfully completed a

nationally recognized course in scuba diving.

•Hollis BC’s must not be used by untrained persons who may not have knowledge

of the potential risks and hazards of scuba diving

•As with all underwater life support equipment, improper use or misuse of this

product can cause serious injury or death.

•Improper use of the oral Inflation/ Deflation or dump valve assemblies may allow

water to enter the BC with a subsequent reduction in buoyancy. Reducing

buoyancy can cause a loss of buoyancy control resulting in serious injury or

death.

•Temperature conditions for use (1 to 40 degrees C / 34 to104 degrees F)

•Limitations of dimensions of cylinders (20L single cylinder, or Twin 15 litre

cylinders)

•This is not a lifejacket it does not guarantee a head up position of the wearer at the

surface.

•DO NOT depend on any Hollis BC to save your life under any circumstances.

•Prior to each dive, inspect and test your BC for proper operation. If any part does

not function properly, DO NOT USE!

•In an emergency, Hollis BC’s may not provide face-up flotation in all cases for all

persons.

•DO NOT inhale gases from within any Hollis BC.

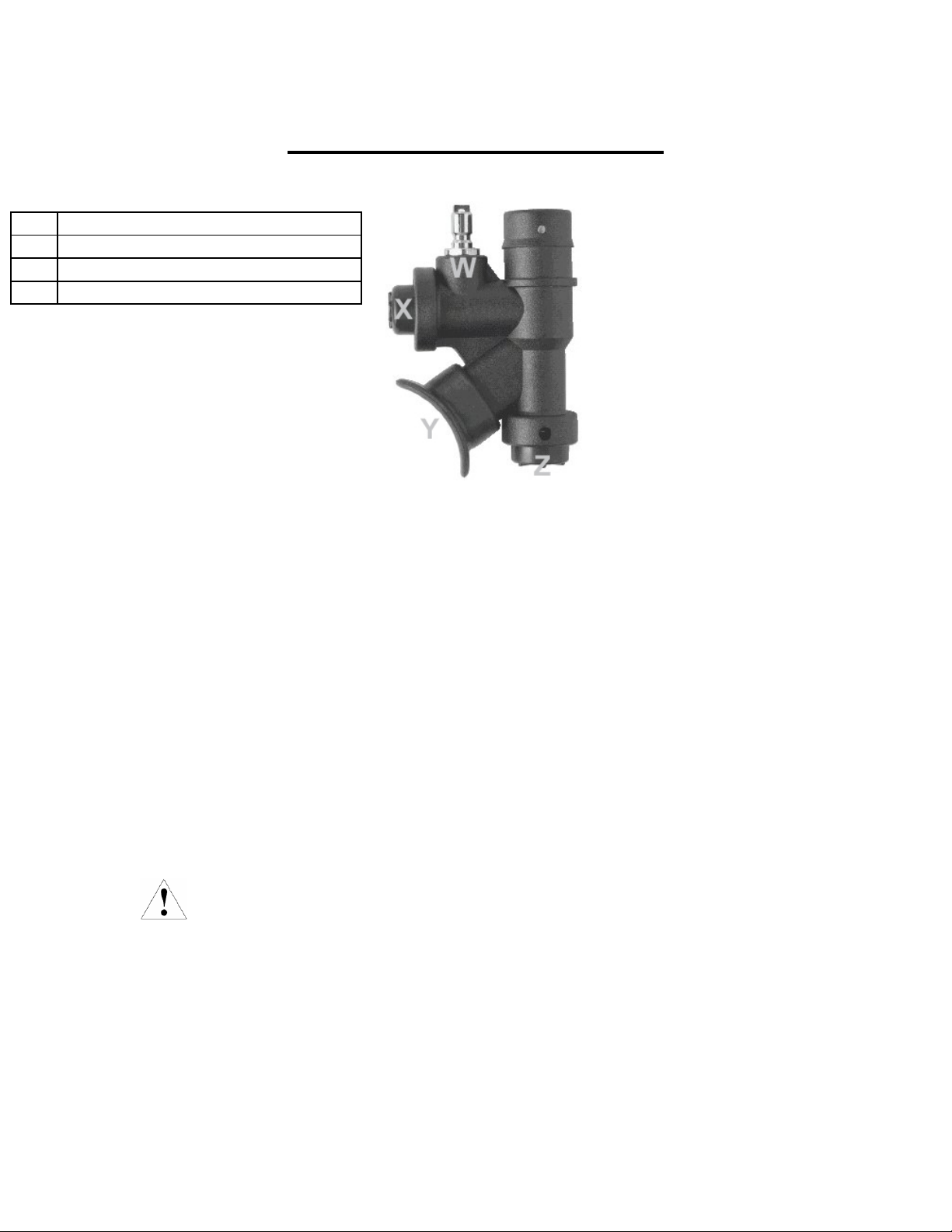

•On the Hollis dual bladder, the bladder against the diver’s back is the primary

bladder. Do not inflate both bladders at the same time, this could decrease the

overall lift provided by the bladder.

•If you do not fully understand how to use your Hollis BC, or if you have any

questions regarding its functions, you should seek instruction in its use from your

authorized Hollis dealer before you utilize this product.

•Read and understand the owner’s guide completely before diving with any Hollis

BC system.

•It is the diver’s responsibility to assure that fully configured, ready to dive

systems are able to achieve neutral buoyancy at the beginning and end of any

dive. Adding Non-Drop weights or switching from a single cylinder configuration

to twin cylinder configuration can add significant in water weight.

5