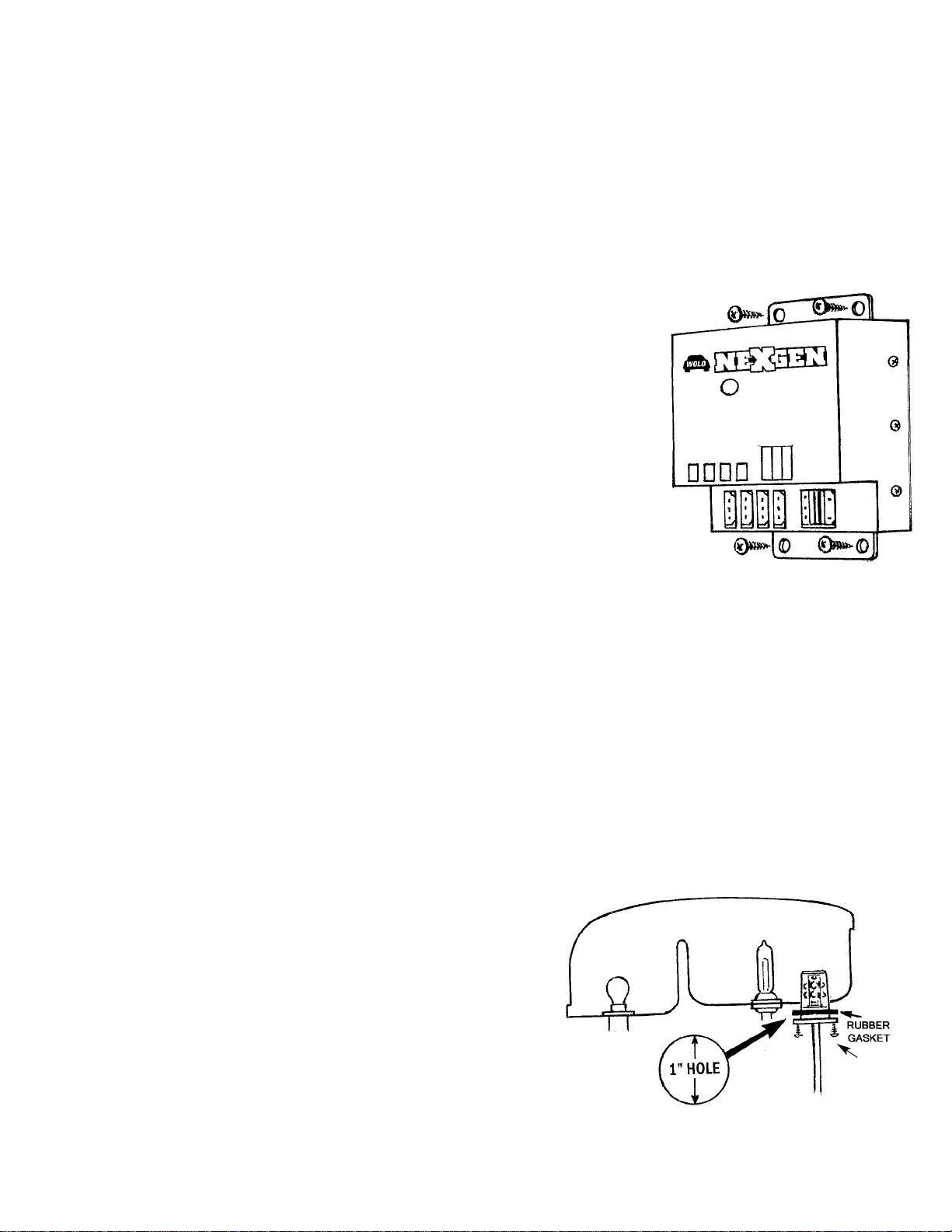

NEXGEN 40 WATT / 4 OUTLET 12-24 VOLT

POWER SUPPLY & LED LIGHT KIT

15 Different Light Patterns 8504 SERIES

INSTALLATION INSTRUCTIONS

Your purchase of Wolo’s NEXGEN LED light system is the perfect choice to compliment your vehicles

emergency warning lights. Wolo’s LED kits are manufactured with the finest materials. Each light is tested to

meet our high standards to ensure that all functions work perfectly. Our quality workmanship and components

are Wolo’s assurance that this product will provide years of dependable service. If you need help using or

installing your new Wolo warning light, our technicians are available to answer your questions, Monday thru

Friday, from 9 AM to 4 PM EST at: 888-550-4676.

Before installing the LED it is important to read these instructions completely. The lives of people are

dependent on the proper installation. The person installing the power supply must have advanced knowledge

of the proper method of installing emergency warning lights to a vehicle as well as knowledge of the vehicle's

electrical system. Again, read this manual completely and note any messages marked ‘‘IMPORTANT” or

‘‘WARNING”. A safe installation will prevent serious injury or damage to the vehicle.

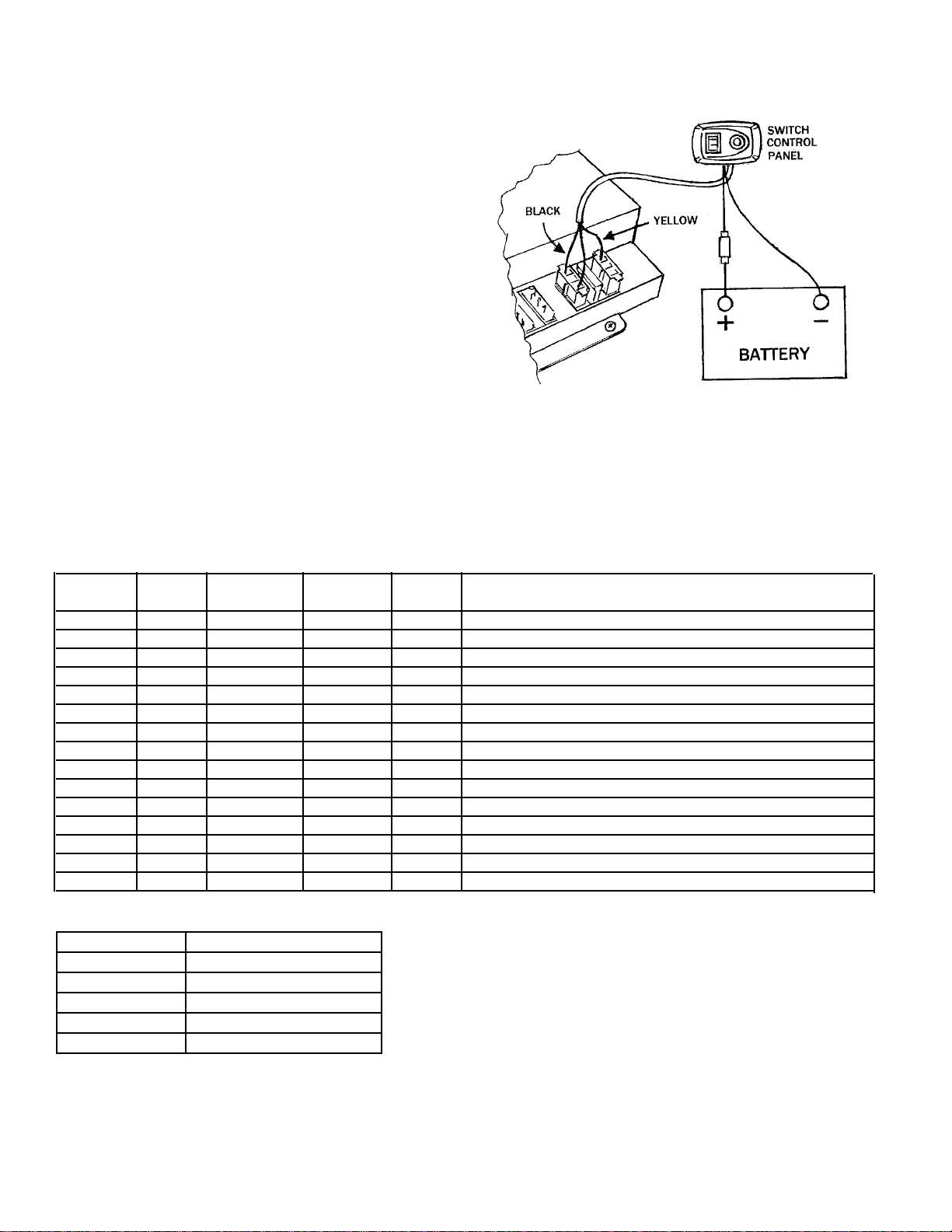

NEXGEN is completely wired and does not require any wiring inside the power supply. There are four (4)

power cables included in the kit; two (2) that are 3 meters / 9.8 ft. in length for installation in front of vehicle

and two (2) that are 5 meters / 16.4 ft. in length for installation in rear of vehicle. Also included in the kit is a

control panel, dash mountable with an on/off switch and a push button switch to change the LED light pattern,

all which is required for a successful installation.

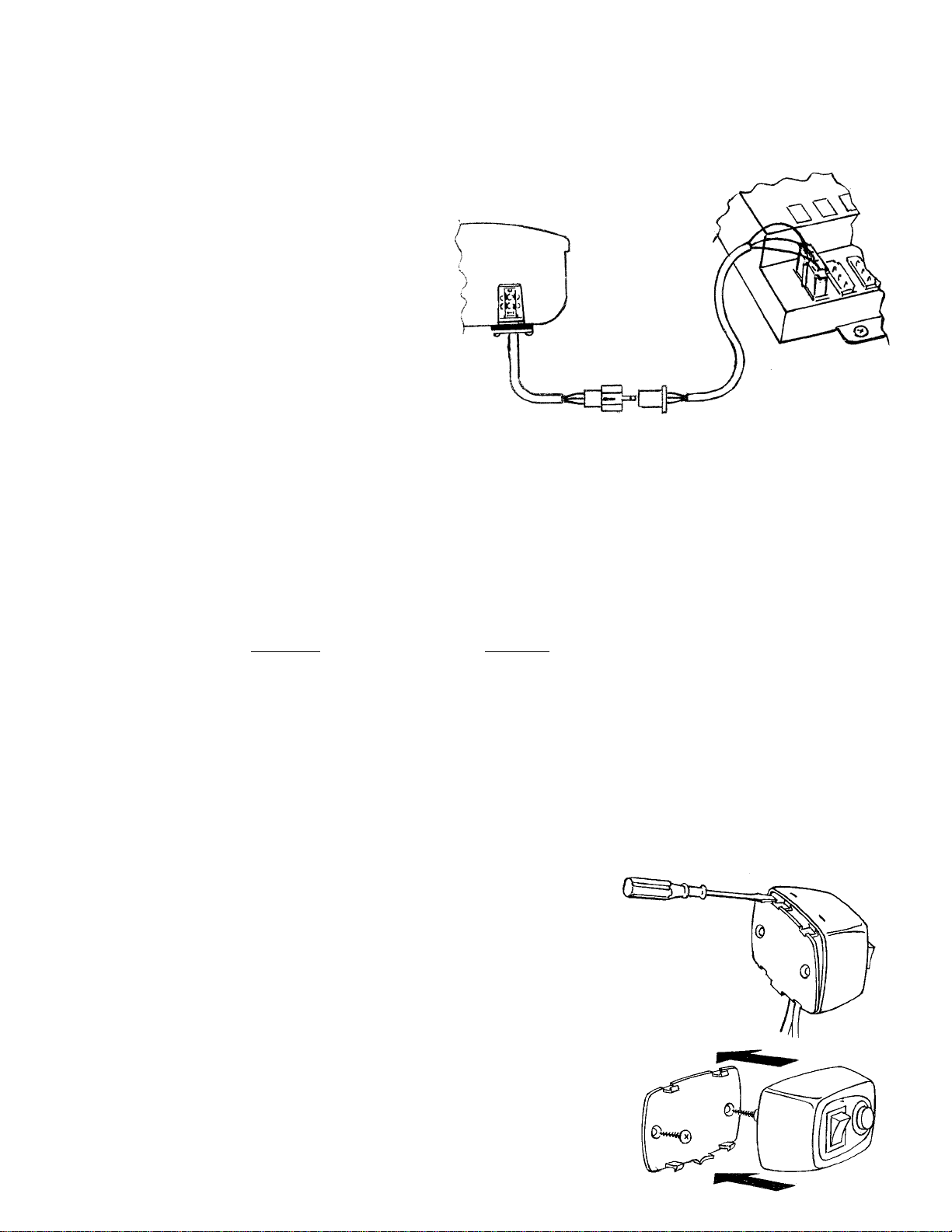

Installation of NEXGEN requires drilling to the vehicle. The installer must carefully inspect both sides of any

location that will be drilled to ensure that there are no components, wires and or any vehicle parts that could

be damaged when drilling.

IMPORTANT: Always de-burr any drilled holes to ensure that there are no sharp edges. Install a rubber

grommet into all metal holes that the wires are being routed through.

Always refer to the vehicle’s shop manual for the deployment location of the air bags. Never install the control

panel switches, wires and/or components in the deployment area of any air bag. Improper installation could

reduce the effectiveness of the vehicle's air bag system and/or project an object that could cause serious

personal injury or death to the driver or passenger. The user/installer assumes all responsibility to properly

access a safe mounting location for the switch control panel, so to provide ultimate safety to the driver and

passengers inside the vehicle.

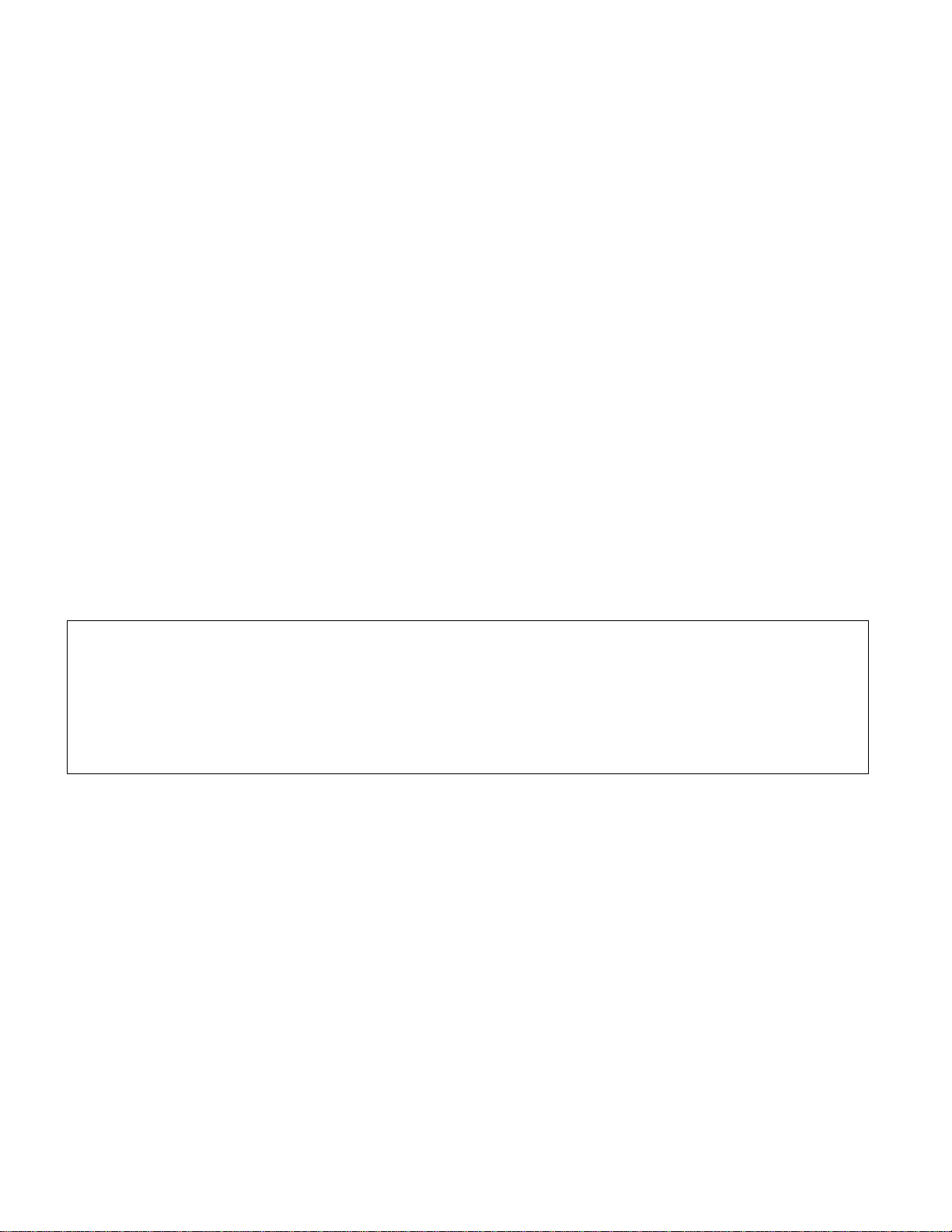

All NEXGEN models produce both low voltage and low current. To operate this product at peak performance,

the black wire should always be connected directly to the (-) negative battery post, or under a metal body bolt.

If the length of the black wire needs to be made longer, use a minimum 18 gauge or heavier.

The vehicle operator and/or maintenance department should inspect the light system frequently to ensure that

all LED heads are functioning and are securely held in the vehicle’s light assembly.

These installation instructions should always be kept and stored in a safe location so that they can be referred

to when information, maintenance or reinstallation is required. Failure to follow all safety precautions and

installation procedures as outlined in these instructions could result in property damage to the vehicle, serious

injury or death to you or others.