Page 5

SHARPENINGINSTRUCTIONS

Grinding grit can damage your eyesight. Make sure you are wearing

approvedsafetyglasses before starting your grinder.

BasicstepswithTru-Grindsharpening

These are the basic adjustments to be made when sharpening all

woodturning tools with the Tru-Grind jig:

1.ToolProtrusion - In the setup instructions, we suggested you screw

a block to your bench, approximately 2 inches (50mm) from the edge,

which you use to set the protrusion of the chisel end from the Tru-Grind

Toolholder. This setting must be consistent every time you grind the tool.

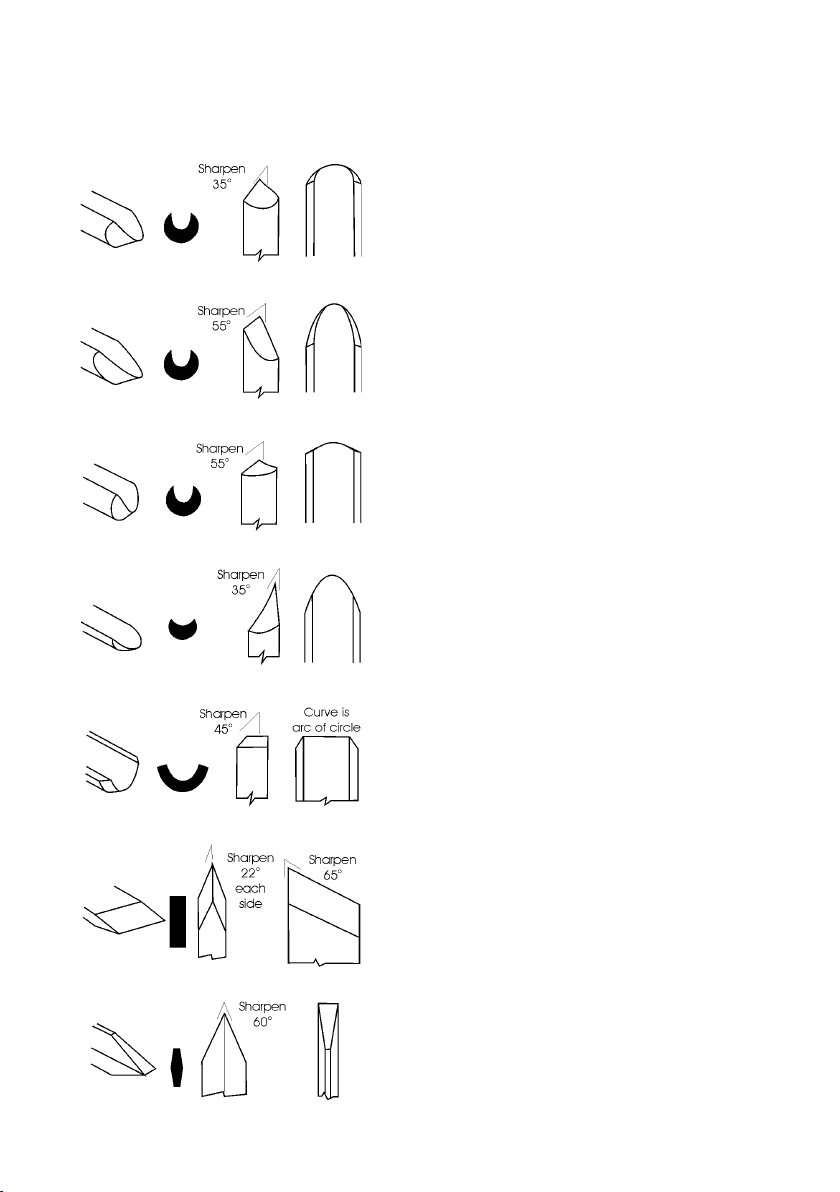

2.ThepositionoftheToolholderPivotLeg determines the style of grind.

Use position 1 for grinding standard traditional bowl gouges and roughing

gouges. This will give a bevel angle which is similar on the sides and on

the nose. The greater angle that you adjust the Pivot Leg to the Toolholder

head (or the greater the number), the more will be the difference in bevel

angle between the nose and the sides of the tool, and the further back you

will grind the sides of the gouge, i.e. increasing the length of the ngernail.

You may need to nd the closest setting notch to the previous angle and re-

grind your gouge so that this setting can be used for future re-grinds.

Position 9, with the Pivot Leg pushed all the way forward, is used for

grinding scrapers and ring tools.

3.AdjusttheBase-slide. After steps 1 and 2 above are set, you must

adjust the Base-slide in or out to get the desired angle of your bevel,

particularly on the nose of the chisel.

4.Recordthesetting. For each chisel write down, or record in some other

way, the angle setting of the Toolholder and extension of the Base-slide.

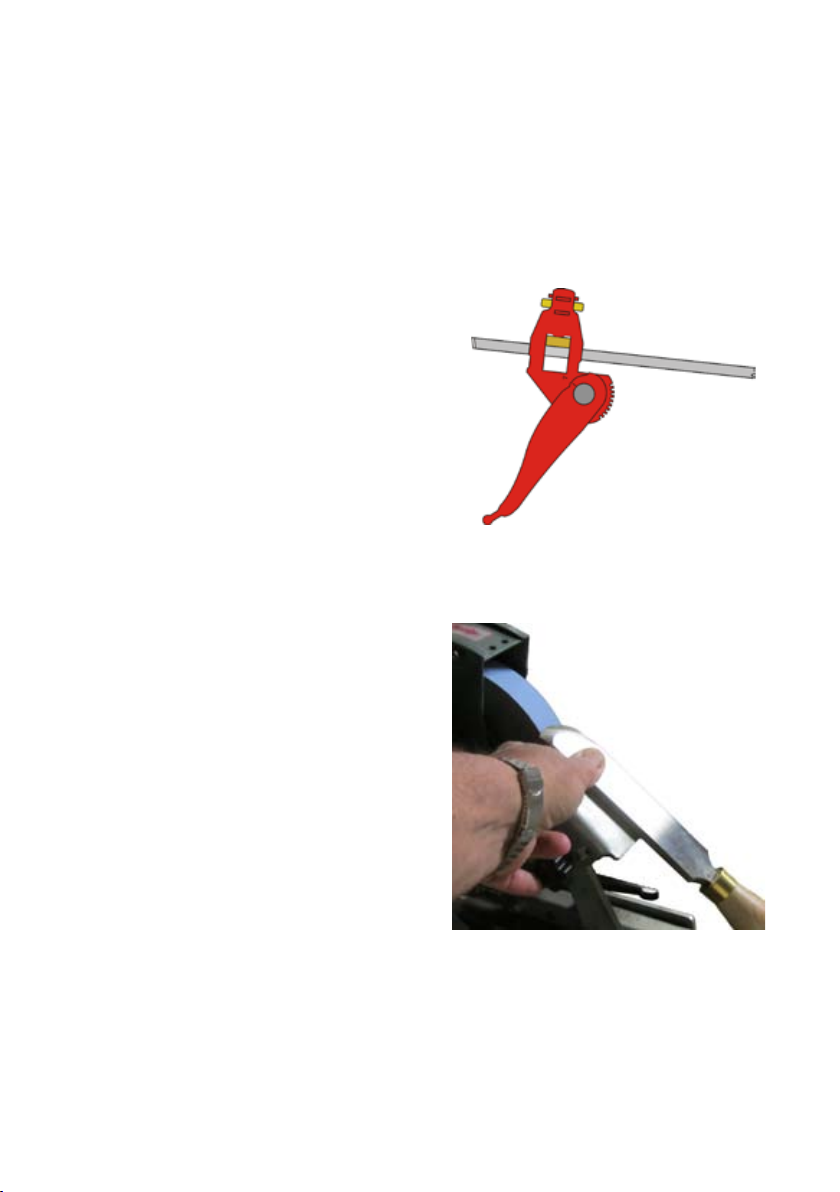

AidstoSharpening. As the grindstone will wear and result in your

recorded Base-slide positions being erroneous, make or obtain a jig which

will repeatedly and accurately set the distance between the grindstone and

the pivot point on the Base-slide.

To have a good example of a standard grind to refer to, obtain the Woodcut

Tru-Grind Proler.