TABLE OF CONTENTS 1_______________________________________

COMPATIBILITY 2_____________________________________________

VARIANTS 2__________________________________________________

DISASSEMBLY 3______________________________________________

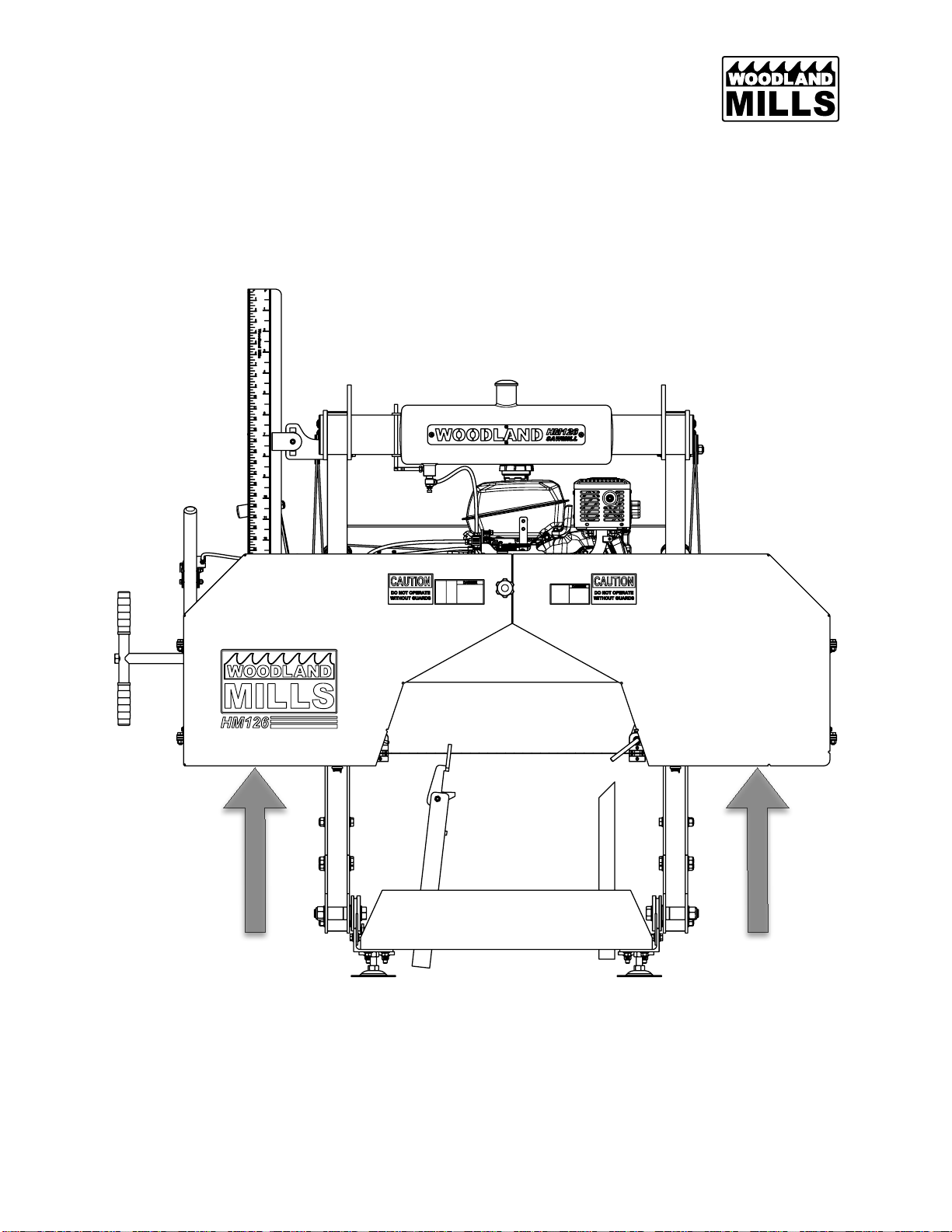

RAISE SAWHEAD 3_________________________________________

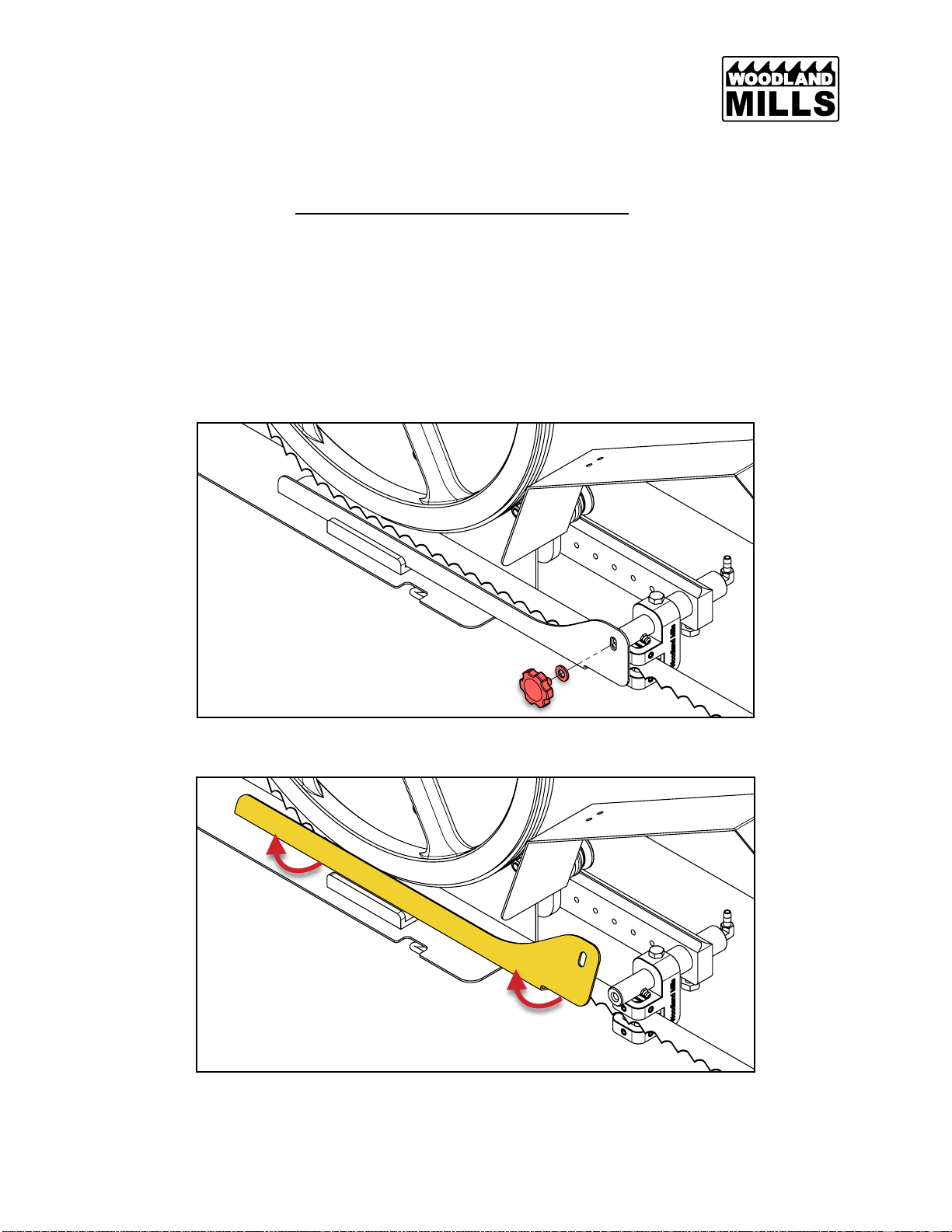

REMOVE ADJUSTABLE BLADE GUIDE 4________________________

REMOVE BLADE GUARD—HM126 & HM130MAX 4_______________

REMOVE BLADE GUARD—HM122 5____________________________

REMOVE GUIDE ARM—HM122, HM126 & HM130MAX 6___________

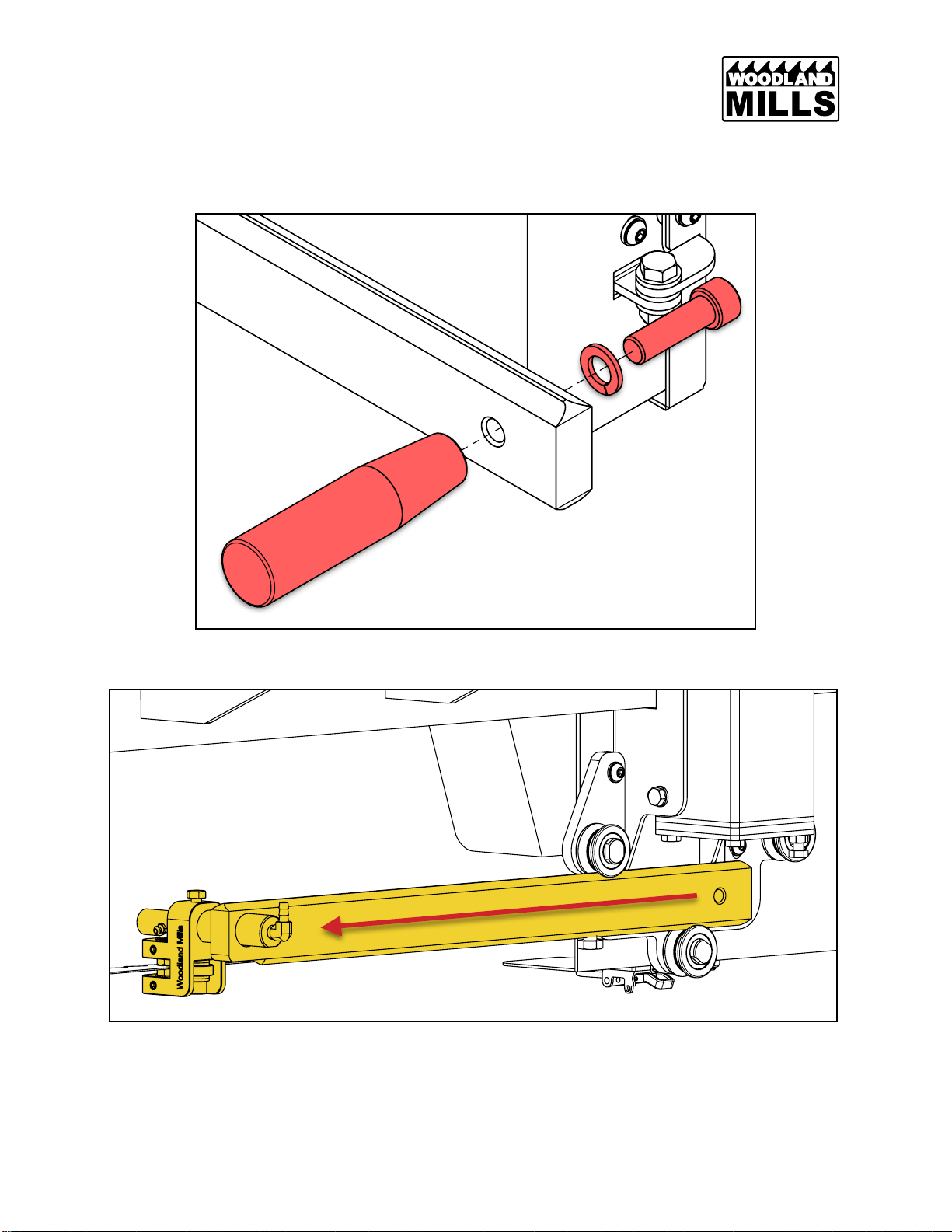

REMOVE GUIDE ARM—HM130 7_______________________________

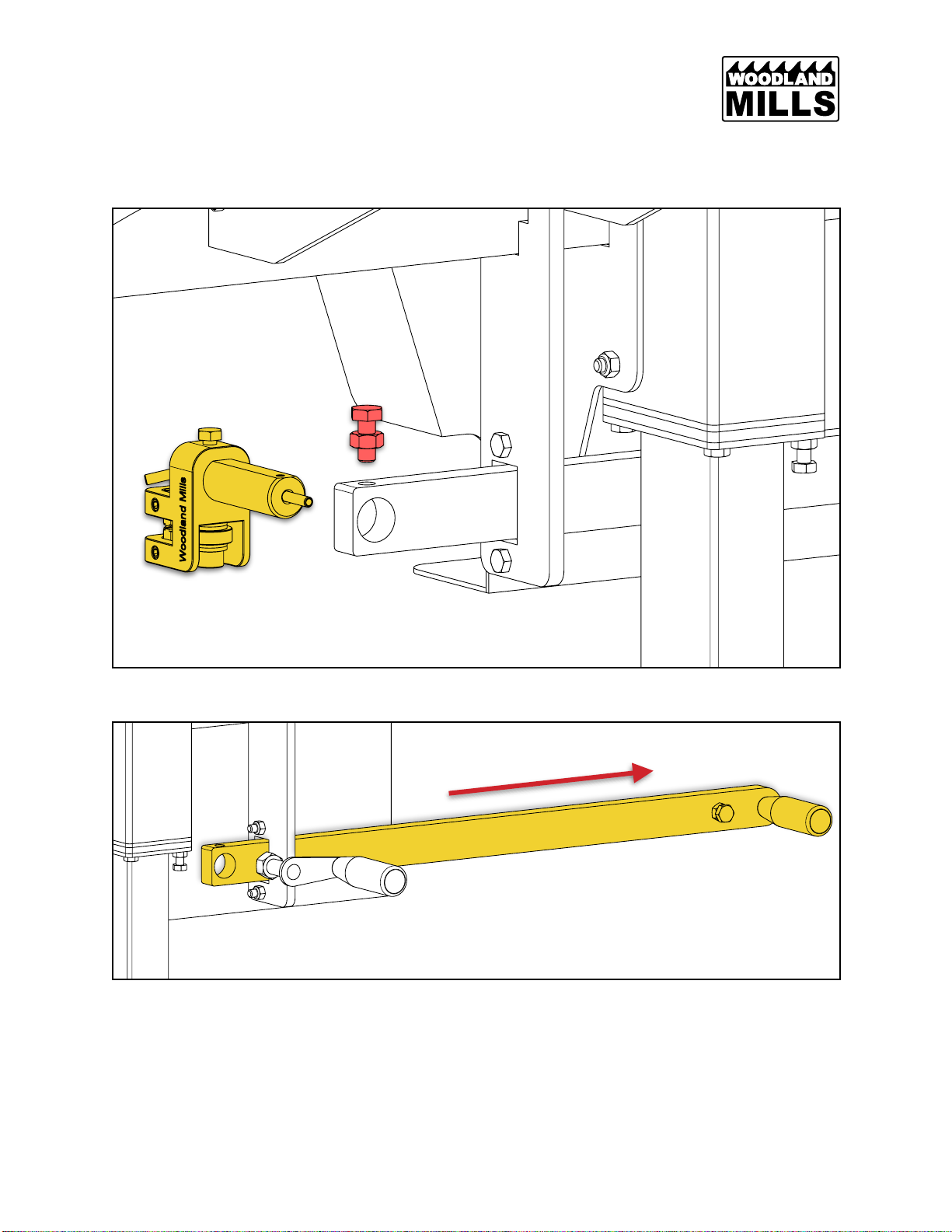

REMOVE CARRIAGE—HM130MAX 9____________________________

REMOVE OLD POST SLEEVE BUSHINGS 10____________________

INSTALLATION 11_____________________________________________

ASSEMBLE UPPER POST SLEEVE BUSHINGS 11________________

ASSEMBLE LOWER POST SLEEVE BUSHINGS 12________________

FULLY TIGHTEN HARDWARE 14________________________________

ABG CALIBRATION—HM130MAX 15_____________________________