f) Turn on the switch of the multi-function syringe, press the air or water into the

water pipe to clean and eliminate the impurity.

[Note 3 ] If the scaling tip has been screwed on tightly and there is ne spray too,

the following phenomena show that the scaling tip is damaged:

a) The vibrating intensity and the pulverization degree become weak obviously.

b) During operating, there is some buzz when the scaling tip is working.

4. Precaution

4.1 usage notice

4.1.1 Keep the scaler clean before and after operation.

4.1.2 The scaling tip, wrench and handpiece must be sterilized before each

treatment.

4.1.3 Don't screw the scaling tip when stepping on the foot switch.

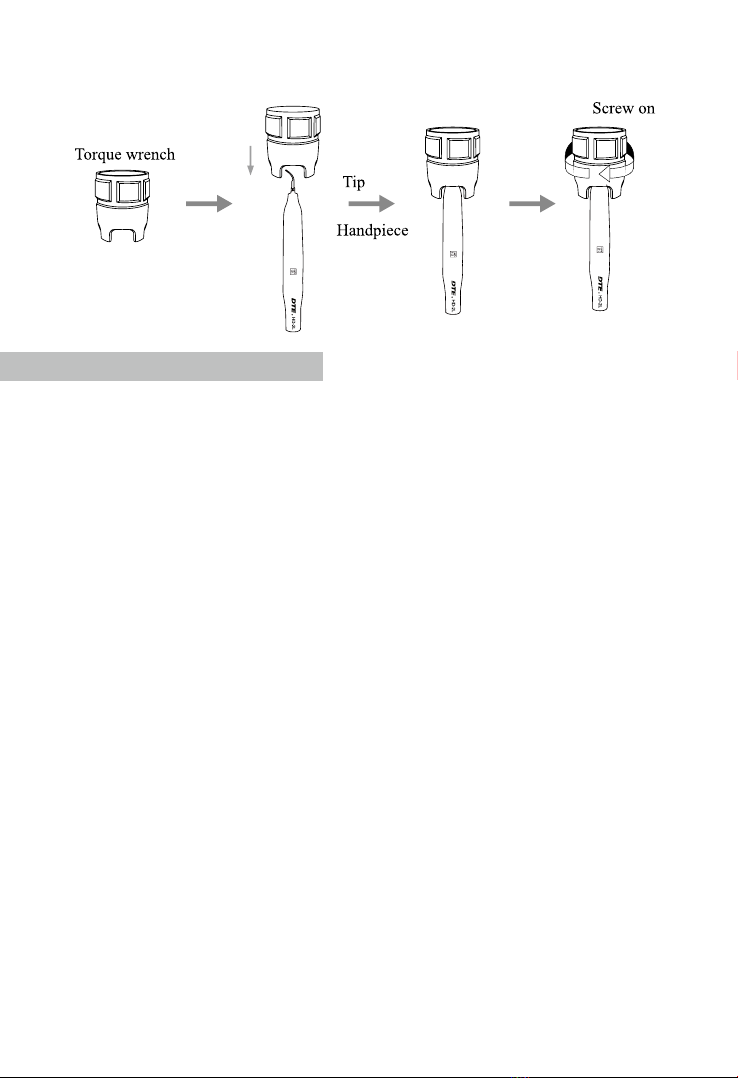

4.1.4 The scaling tip must be fastened. There must be ne spray coming out from

the tip when operating.

4.1.5 Change a new one when the tip is damaged or worn excessively.

4.1.6 Don't twist or rub the tip.

4.1.7 Don't use impure water source, and be sure not to use normal brine instead

of pure water source.

4.1.8 If use the water source without hydraulic pressure, the water surface should

be one meter higher than the head of the patient.

4.1.9 Don't knock or rub the handpiece.

4.1.10 Please put the power plug into the socket easy to pull out, to make sure it

can be pulled out in emergency.

4.1.11 When using the equipment, please keep the water get through smoothy,

otherwise patient's tooth surface would be injured by overheat in the handpiece.

4.1.12 After operating, turn off electrical source, and then pull out the plug.

4.1.13 As a professional manufacturer of medical instruments, we are only

responsible for the safety on the following conditions:

Ⅰ.The maintenance, repair and modication are made by the manufacturer or

the authorized dealer.