7

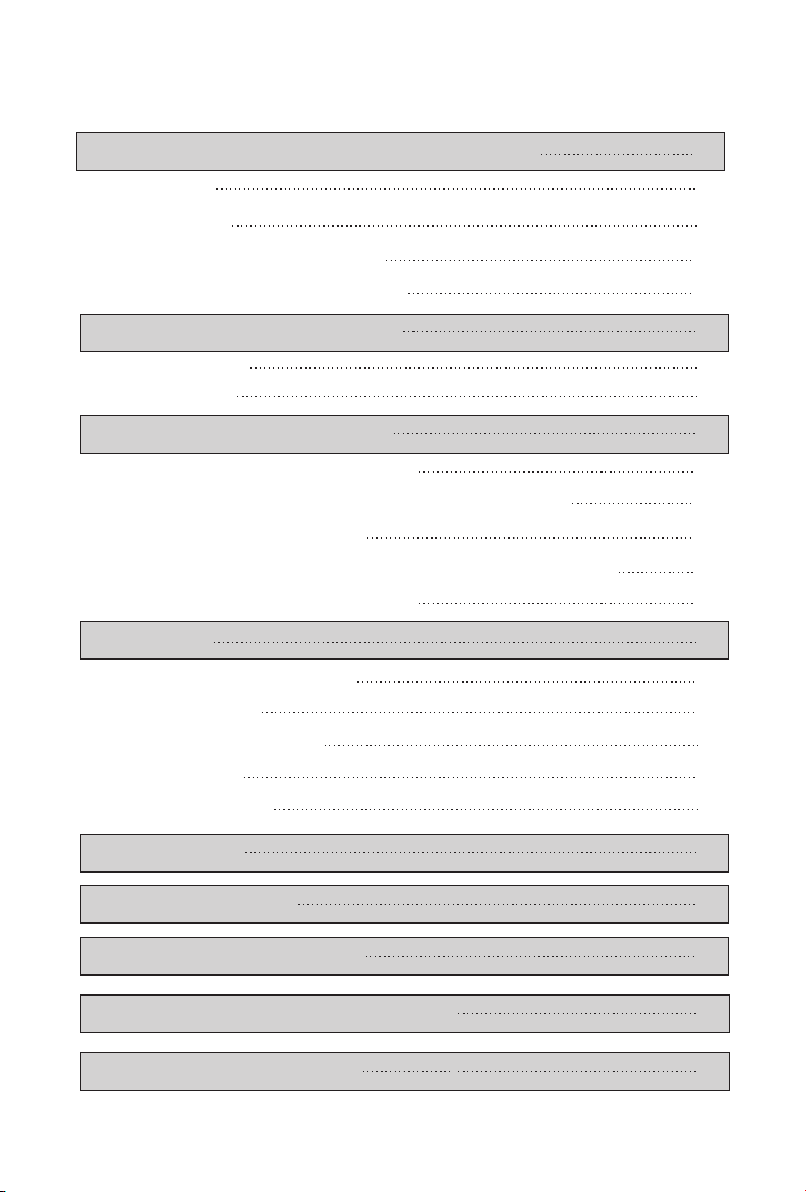

2.1 Scaling function

2.1.1Usage

a) Open the packing box, make sure that all the parts and accessories are

complete according to the packing list. Take the main unit out of the box

and put it on a stable plane.

b) Turn the water control switch to the max based on symbol as shown

as 3.5.2[note 1].

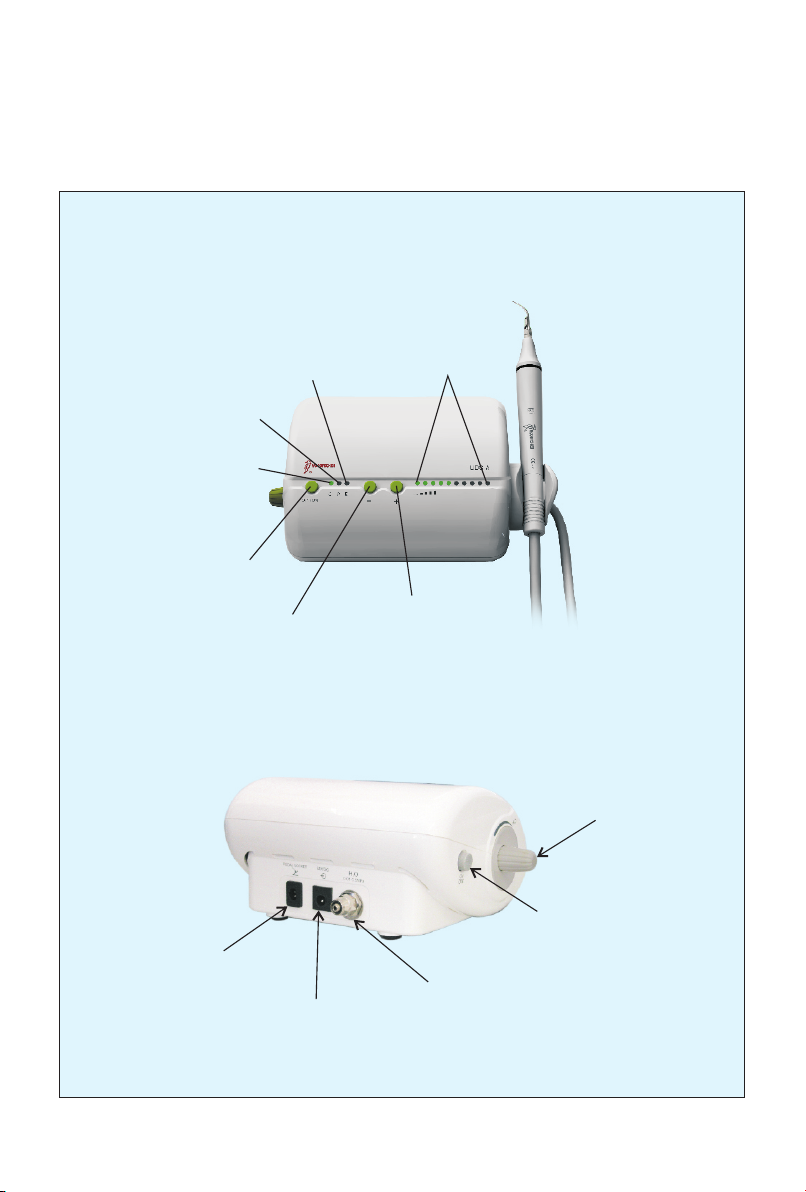

c) Insert the plug of the foot switch to its socket(picture 2).

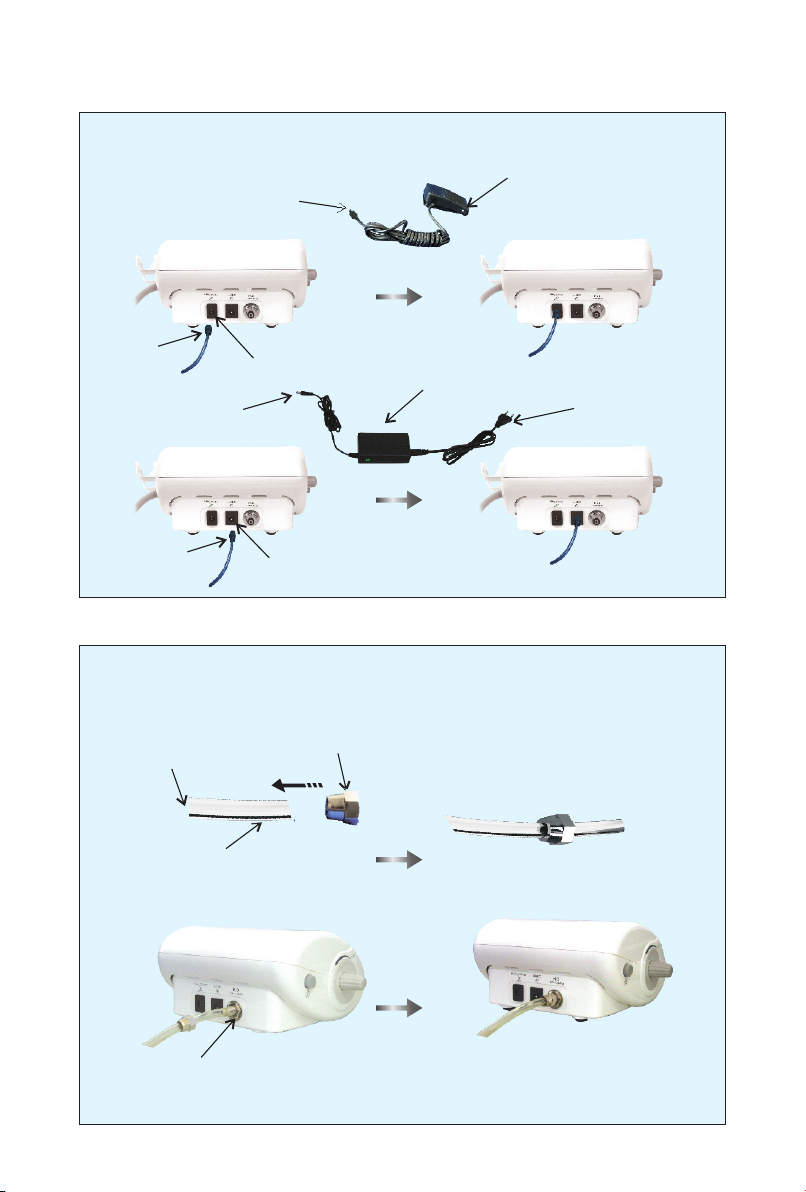

d) Connect one end of the water line to the water entrance, and the other end

to the pure water source(picture 3).

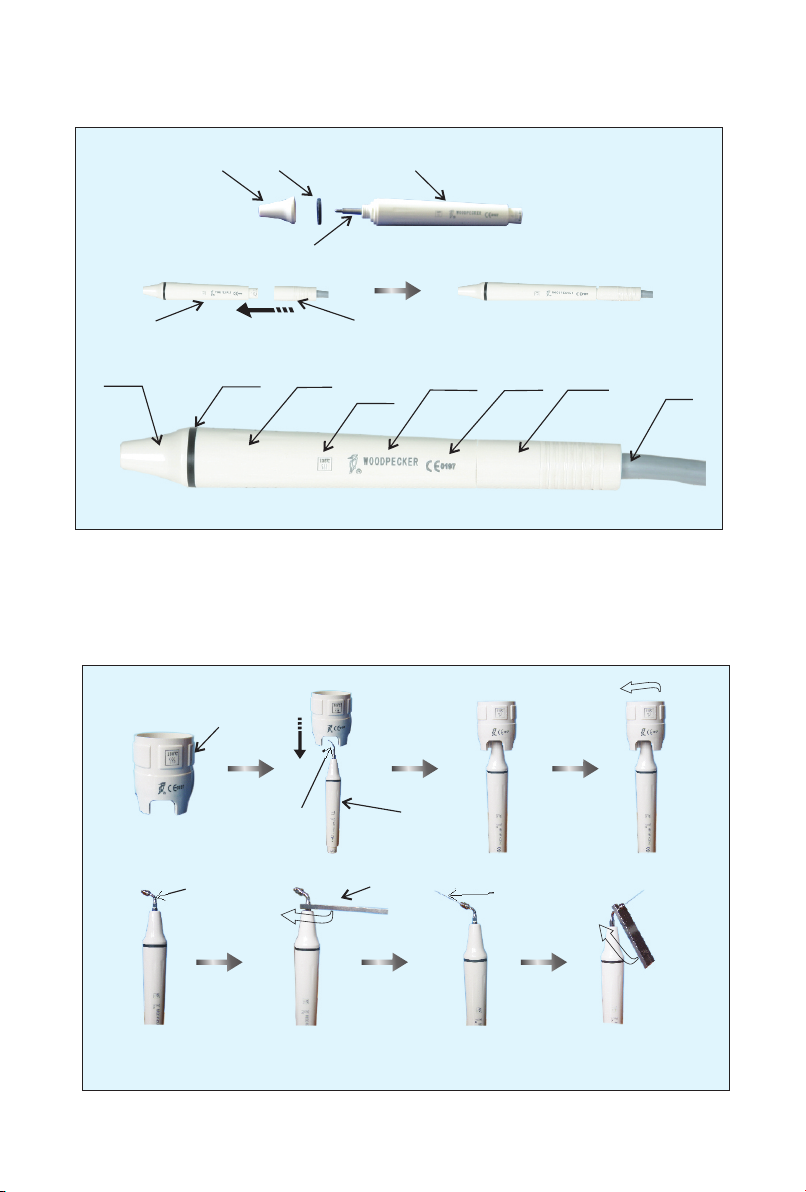

e) Screw the scaling tip tightly to handpiece by torque wrench, then connect

the handpiece and the connector of cable correctly.

f) Insert the plug of the power source to its socket ,then get through to

the electricity (picture 2).

g) Switch on the main unit, then the scaling indicator and the first five lights

of power regulator shine.

h) Select a suitable scaling tip as you need, screw it on the handpiece tightly

by the torque wrench(picture 5).

i) The normal frequency is extremely high. Under the normal working state

of scaling tips , a light touch and a certain to-and-fro motion will eliminate

the tartar without heating. Overexertion and long-time lingering are forbidden.

j) Vibrating intensity: Adjust the vibration intensity as you need, generally

turn the knob to the middle grade. According to patients’ different sensitivity

and the rigidity of the gingival tartar, adjust the vibration intensity during the

clinical treatment.

k) Water volume adjust: Step on the foot switch, and the tip begins to vibrate,

then turn the water control switch to form fine spray to cool down the hand-

piece and clean the teeth.

l) The handpiece can be handled in the same gesture as a pen in hand.

2.Product function and usage