5

intensity should be adjusted during the clinical treatment.

2.2.5 Water adjustment: Step on the foot swtich, the tip begins to vibrate, then

turn the water control switch to form ne spray to cool down the handpiece and

clean the teeth.

2.2.6 The handpiece can be handled in the same gesture as a pen in hand.

2.2.7 Make the tip touch the surface of the teeth lightly, don't use too much

pressure, or else the teeth will be hurt and the scaling tip will be damaged.

2.2.8 After nishing operation, keep the machine working for 30 seconds with

the wate supply, so that the handpiece and the scaling tips can be cleaned.

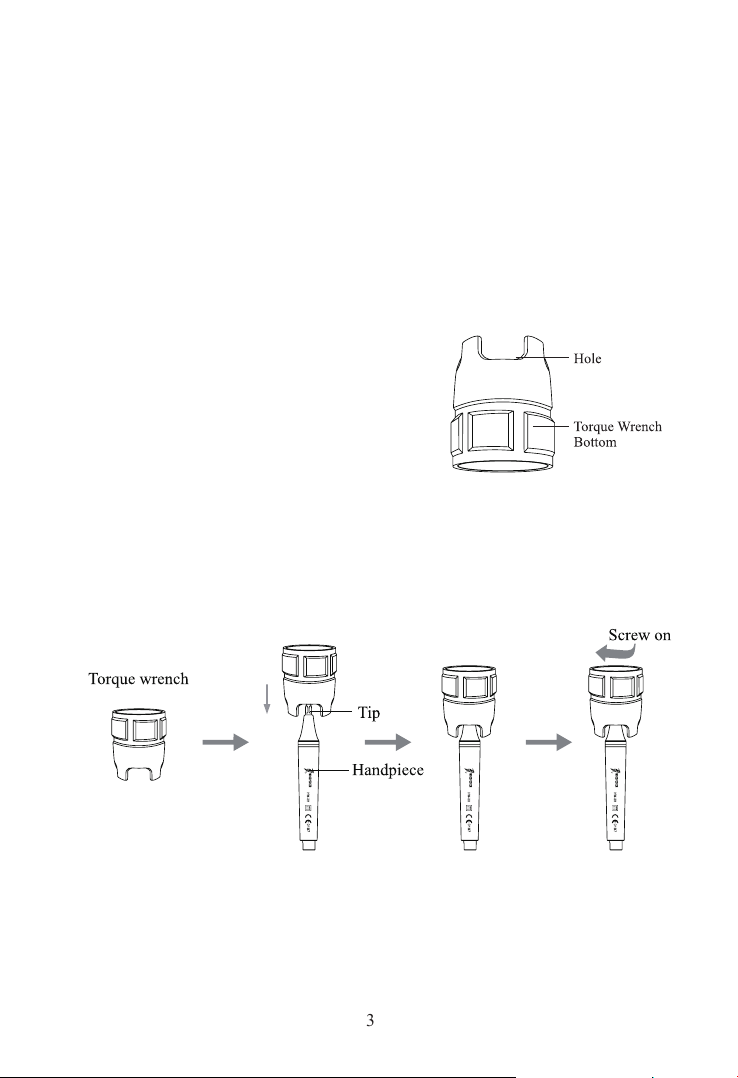

2.2.9 Pull out the handpiece and unscrew the scaling tip, make them be

sterilized.

Notice: Don't pull out the handpiece when the foot switch is stepped on

and the machine is working.

3. Sterilization and maintenance

3.1 Sterilization of handpiece

3.1.1 Autoclaved under high temperature, pressure, time:

134°C, 2.0bar~2.3bar (0.20MPa~0.23MPa), 4min.

3.1.2 Pull out the handpiece and unscrew the scaling tip after every operation.

3.1.3 Pack the handpiece with sterile gauze or bag.

3.1.4 Reuse the handpiece after it cools naturally, in case of scalding hand.

3.1.5 Notice:

a) Clear the cleaning liquid in the handpiece by compressed air before

sterilization.

b) Be sure that the scaling tip has been unscrewed from the handpiece, and it

can not be sterilized with others.

c) Please pay attention that whether the outer of the handpieces damaged

during the treatment or sterilization, don't smear any protective oil on the surface

of handpiece.

d) There are two waterproof "O" rings at the end of the handpiece. Please

lubricate them with dental lube frequently, as sterilization and repeating pulling

and inserting will reduce their life-span. Once they are damaged or worn

excessively, please change new ones.

e) The following sterilizing methods are forbidden:

① Put the handpiece into any liquid for boiling.

② Put the handpiece in disinfectors such as alcohol, iodine or glutaraldehyde.

③ Put the handpiece in oven or micro-wave oven for baking.

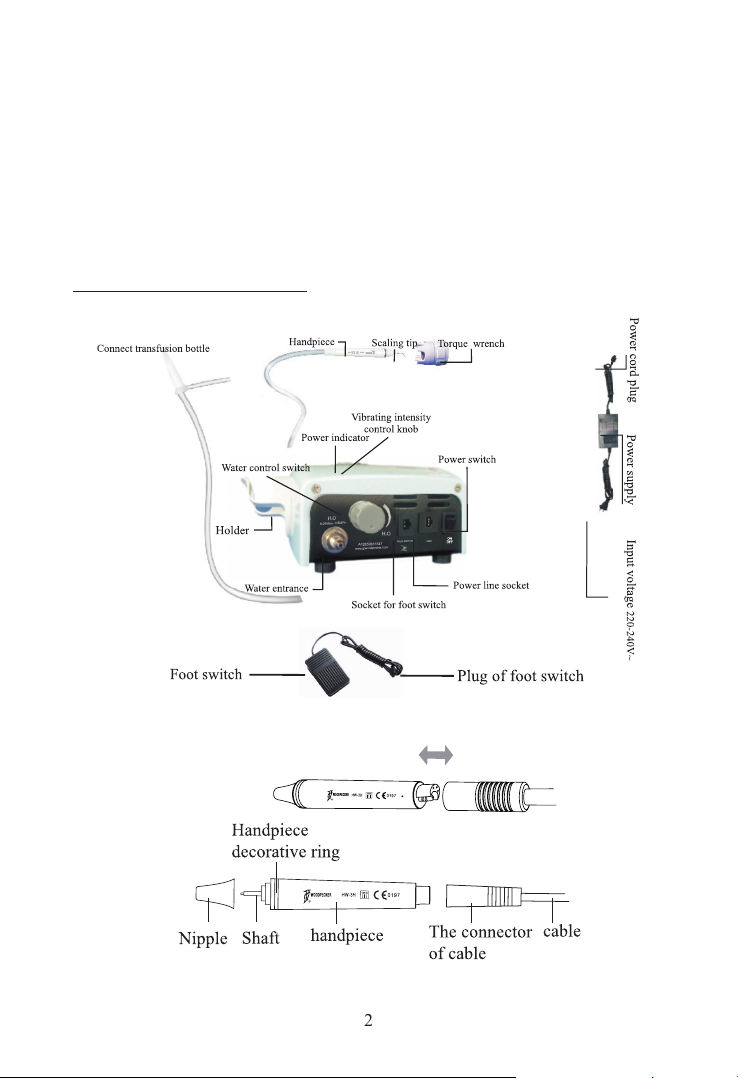

3.2 Sterilization of the scaling tip and endochuck

All the scaling tips can be autoclaved to 134°C.

3.3 The sterilization of the torque wrench

The wrench can be sterilized under high temperature and pressure.