Woodstock Soapstone Palladian 202 User manual

Other Woodstock Soapstone Fireplace Accessories manuals

Popular Fireplace Accessories manuals by other brands

Town & Country Fireplaces

Town & Country Fireplaces 22150051 instructions

Travis Industries

Travis Industries 33 DVI installation instructions

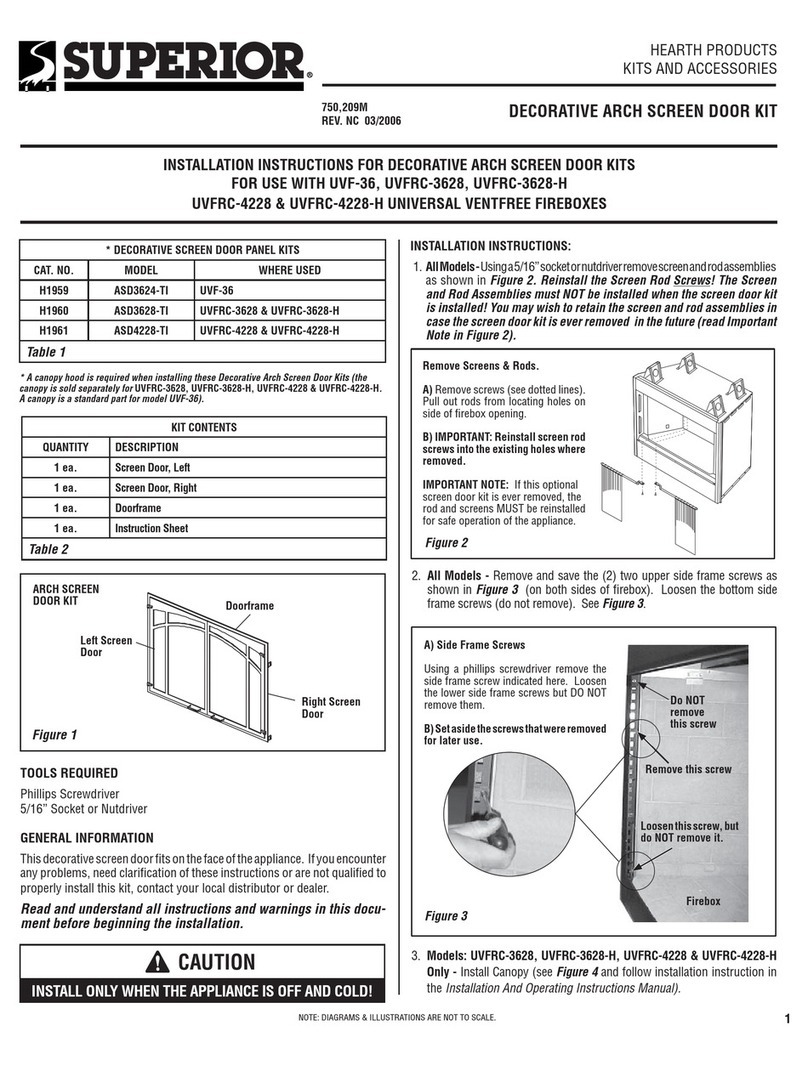

Superior

Superior ASD3628-TI installation instructions

pleasant hearth

pleasant hearth OFP28WG operating manual

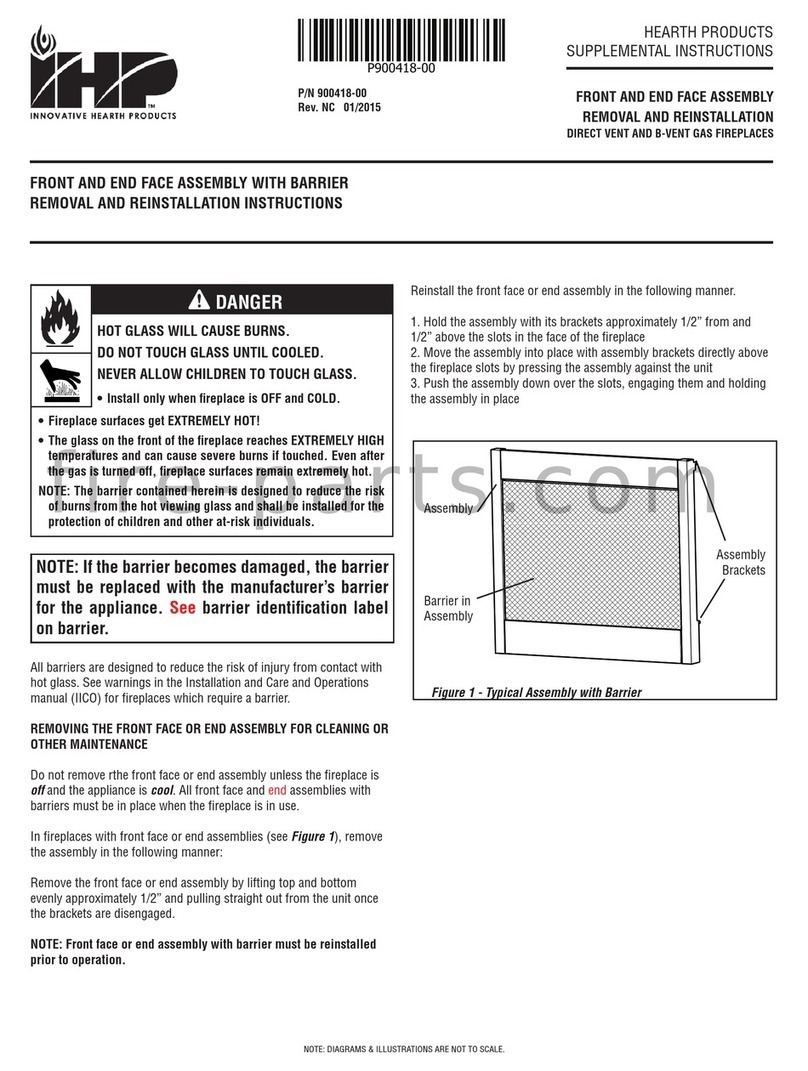

IHP

IHP Astria Series manual

Firegear

Firegear FG-H-2110SS Installation and operating instructions

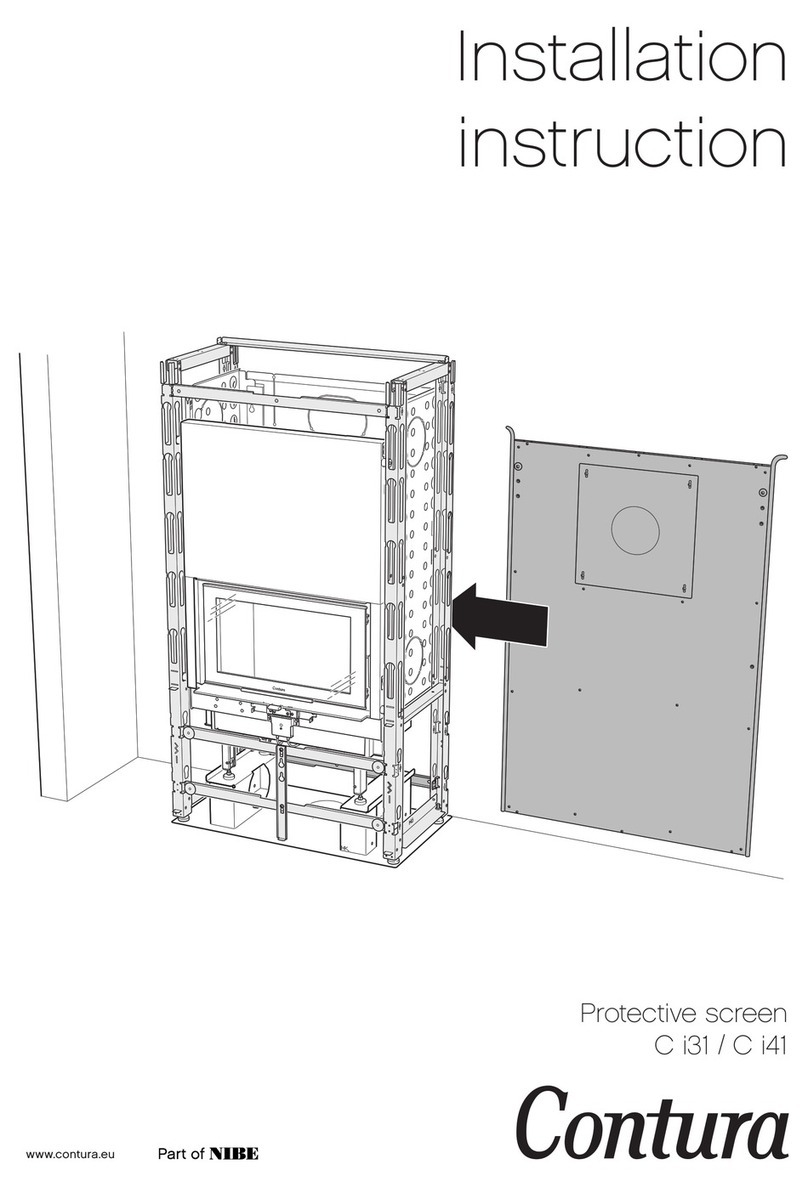

Nibe

Nibe Contura C i31 Installation instruction

kozy heat

kozy heat KZK-052 manual

SimpliFire

SimpliFire SF-WM36 Service manual

Bluegrass Living

Bluegrass Living BC18NR OWNER'S OPERATION AND INSTALLATION MANUAL

pleasant hearth

pleasant hearth IRIS SCROLL quick start guide

Cooke

Cooke Glass Wind Guard instructions