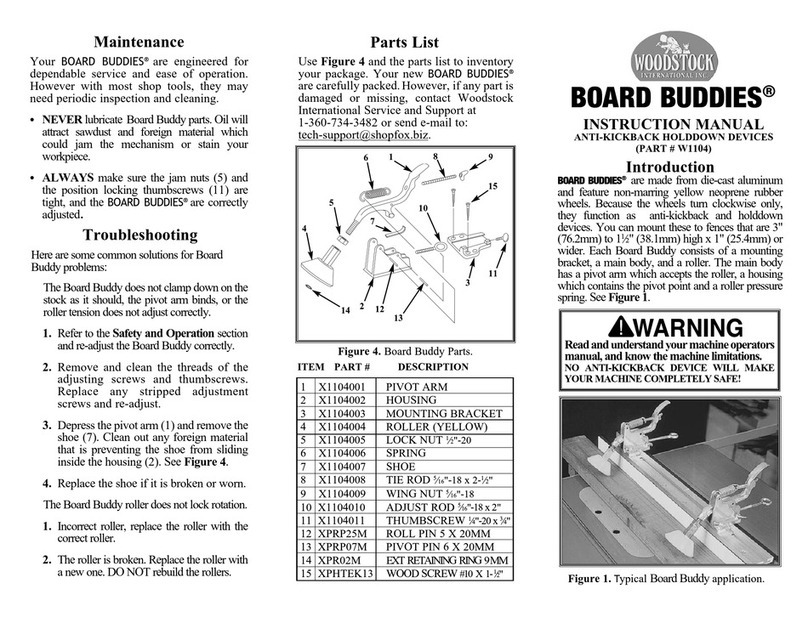

To assemble your BOARD BUDDIES®, see

Figure 4 for item numbers and do these steps:

1. Unplug your machine!

2. Thread the lock nut (5) onto each pivot

arm (1).

3. Thread the roller (4) onto each pivot arm

no less than 1⁄2" (12.7mm), and tighten the

lock nut (5) against the roller nut (4).

4. Slide the housing (2) into the mounting

bracket (3) and tighten the thumbscrews (11).

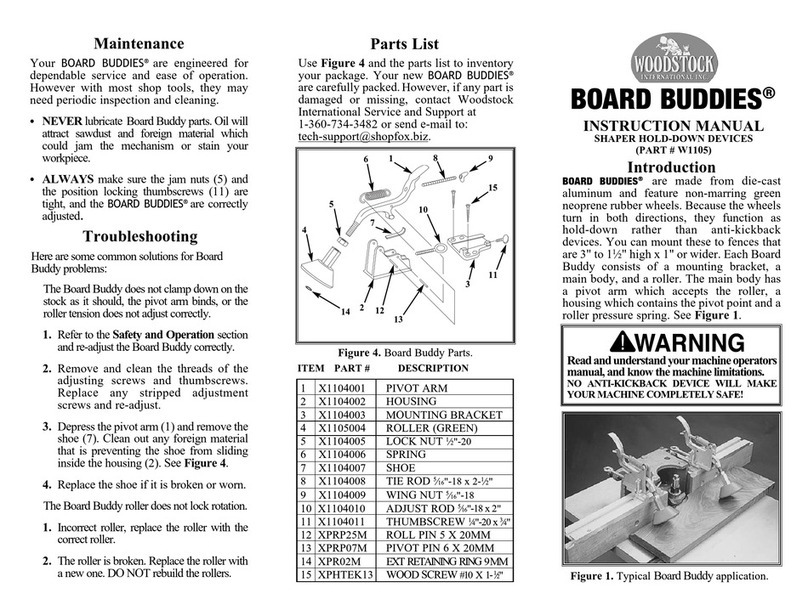

To install your BOARD BUDDIES® see Figures 1

and 2, and do these steps:

1. Make an auxiliary wood fence that is

approximately 3" (76.2 mm) tall, 1" (25.4 mm)

thick, and is the length of the machine fence.

2. Mount the auxiliary wood fence to your

machine with countersunk fasteners.

3. Position the mounting bracket on the

auxiliary fence so it does not protrude into the

path of the stock. See Figures 1 and 2.

4. Position the rollers so they are not closer

than 1/2" (12.7 mm) to the front and rear of the

saw blade. See Figure 1.

5. Make sure the rollers do not interfere

with guard operation and other saw

controls. Reposition the mounting

brackets if there is any interference.

6. Mark the FRONT screw hole locations

and drill the pilot holes into the wood fence

for the wood screws (REAR holes are for

the optional track). See Figure 2.

7. Install the mounting bracket with the

provided wood screws.

BOARD BUDDIES®help prevent kickback by

maintaining pressure against the stock with counter

clockwise rotating rollers. See Figures 1 and 2.

1. Turn the saw motor so the blade is parallel

to the fence and the blade rotates clockwise.

2. Position the infeed roller as far out as possible

in the mounting bracket, place the outfeed

roller between the line of cut and the saw fence,

and tighten the position locking thumbscrews.

3. Adjust the roller nut, the lock nut, and the

thumbscrew so the roller height is approximately

1/8" (3 mm) less than the stock thickness.

4. Turn the roller pressure adjustment wing

nut so the roller applies a firm pressure on

the stock, but does not tilt the Board Buddy

off of the fence or sliding rack.

5. Make sure BOARD BUDDIES®DO NOT touch

the saw blade during machine operation.

6. DO NOT adjust or reposition the BOARD

BUDDIES®while the machine is running. Wait

until the machine comes to a complete stop

before making any adjustments.

7. Keep your hands away from all cutting tools,

and feed stock evenly and smoothly.

Figure 3. Board Buddy Details.

Pivot Arm

Mounting

Bracket

Roller

Pressure

Spring

Roller

Pressure

Adjustment

Wing Nut

Roller

Height

Adjustment

Screw

Main Body

Roller

Roller

Nut

Lock

Nut

Figure 2. Auxiliary wood fence and an

optional sliding track.

Make sure your machine is

unplugged and the saw blade has

stopped before you assemble,

install, or adjust BOARD BUDDIES®.

Otherwise serious personal injury

could result!

Assembly and Installation Safety and Operation

A roller nut that is not threaded on the pivot

arm far enough or a loose lock nut could

render the hold-down feature useless and

could cause personal injury.

Optional

Sliding

Track

Use the Front

Mounting Holes

for Wood Screws

and Wood Fence

Use the Rear

Mounting Holes

for Machine

Screws and

Sliding Track

Auxiliary

Wood Fence

Mounting

Bracket

Your BOARD BUDDIES®are partially assembled

from the factory; however, some minor assembly

and adjustment is required using Figure 3 and

Figure 4 for reference.

The Board Buddy brackets (3) can be installed

directly on an auxiliary wood fence (not included)

or an optional sliding track (12" part # W1107 or

24" part # W1108 not included). The optional

sliding track also mounts to the auxiliary wood

fence. See Figure 2.

Position

Locking

Thumbscrews