-3-

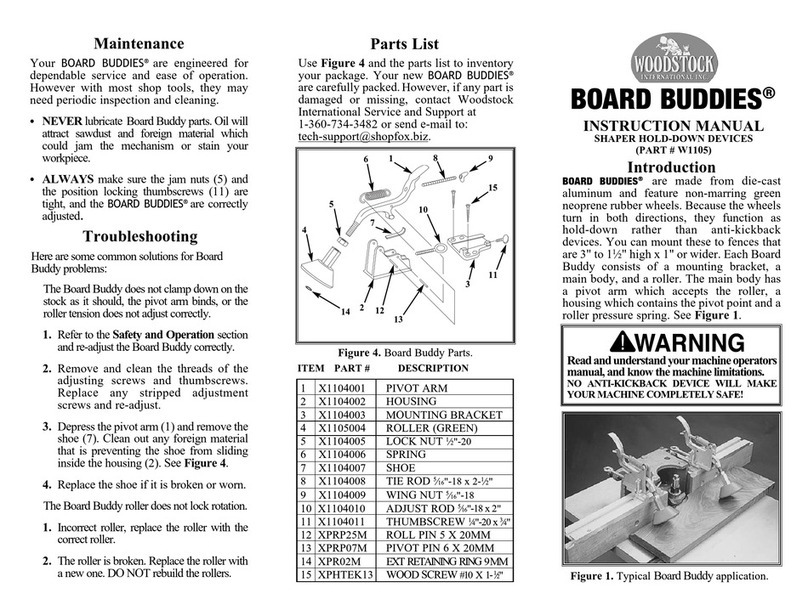

3. Layout the mounting holes on the template as shown

in Figure 6.

• Place the holes in the template so the moulding

blank will mount with 4" of the template showing

in front of the mounting blank and 11⁄2" behind.

• Make sure the holes are located so that the screws

will not be hit when moulding.

• If you are attaching multiple sections to the same

template, make sure that there are mounting

holes for each section.

4. Drill and countersink the mounting holes.

5. Mount the moulding blank to the template with

wood screws. Make sure the screws are short enough

so they will not be hit by the moulding blades.

Operations

To cut curved mouldings, do these steps:

1. Disconnect power to the planer/moulder.

2. Place the template with the moulding blank against

the base plate bearing and tighten the vise bearings

against the template. After the initial contact, turn

the crank 1 to 11⁄4 turns to apply adequate pressure.

3. Make sure the edge of the moulding blank aligns

with the edge of the blades. If the moulding blank

does not align with the blades, remove the screws

securing the base plate to the support studs (Figure

7) and adjust the base plate to align the moulding

blank. Tighten the mounting clamps securing the

base plate to the planer/moulder before moulding.

4. Adjust the cutterhead height as instructed in the

planer/moulder manual.

5. Turn the planer/moulder ON and feed the template

between the bearings on the base plate and into

the machine. Note: The template will need to be

supported by a roller stand or a person as it is fed

through the planer/moulder.

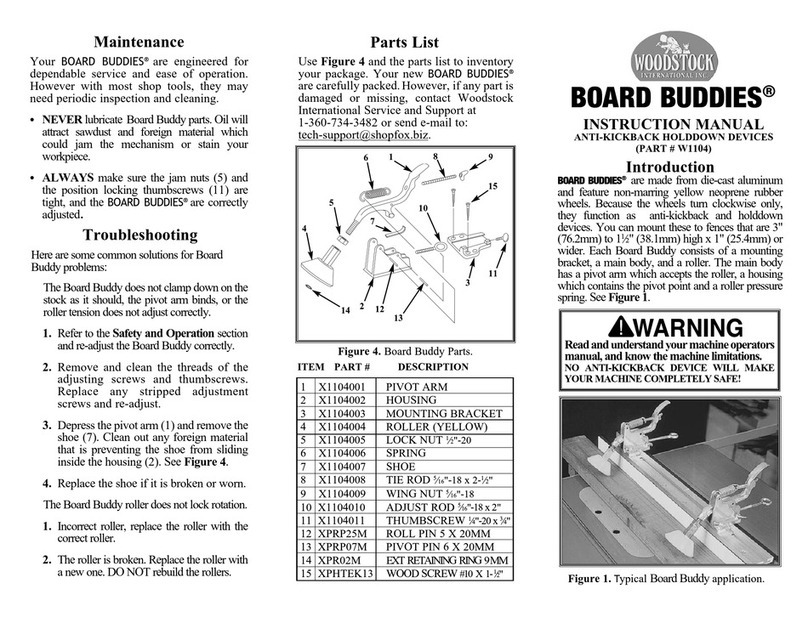

Figure 6. Attaching the moulding blank.

Keep all mounting screws clear of the blade path to

prevent serious personal injury and damage to the

planer/moulder (see Figure 6).

Figure 7. Remove screws to adjust the

base plate.