Manual 54065 PGA-EG, PGG-EG, PGM-EG Installation

Woodward 7

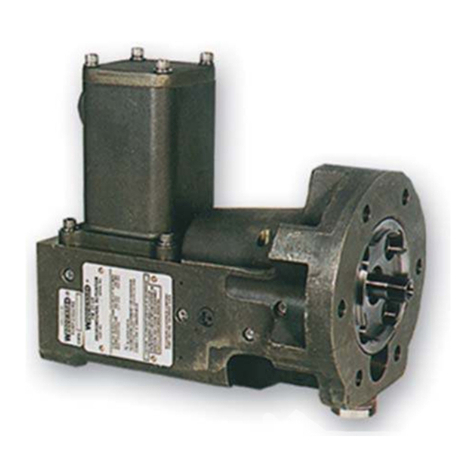

Booster Servomotor

Make all hydraulic Connections from the booster to the PG-EG governor/actuator

(refer to manual 36684, Booster Servomotor). The booster servomotor assists

the internal pump during starting. It provides a rapid increase in oil pressure

which results in a rapid movement of the terminal shaft towards maximum. Refer

to Figures 2A and 2B, Outline of the PG-EG Governor/Actuator, and make the

connections from the booster outlets. Governor fuel position during start-up can

be limited by the fuel limiter (if available) or the stroke-limit screw on the booster.

Heat Exchanger

Make all hydraulic connections from the heat exchanger to the governor. Refer to

Figures 2A and 2B, Outline of the PG-EG Governor/Actuator and to manual

36641, Governor Oil Heat Exchanger. The heat exchanger should be installed as

close as possible to the governor. Install it below the governor’s oil level to

prevent trapping air in the system. Plumbing between the heat exchanger and

the governor must not restrict flow.

Oil Specifications

The same type and grade of oil used in the prime mover can be used in the

governor if it meets heat and viscosity requirements.

Oil contamination is the major cause of governor/actuator troubles.

Use only new oil to fill the governor/actuator. Containers used for

filling the actuator must be clean and should be rinsed with a light

grade of the same oil before use.

The PG-EG oil supply is self-contained. Sump capacity is about 7 US quarts (6.6

L). Fill the sump through the dip-stick port. It may be necessary to add oil after

the governor is first started to restore oil to the proper level on the dipstick.

Proper level is between the “ADD” and “FULL” marks. Check the oil level with the

governor running. Oil will splash from the test location during major governor

transients.

When using a booster servomotor or heat exchanger, be sure that oil

lines, booster, and the heat exchanger are full of oil before starting

the prime mover.

Whenever the PG-EG is filled, always check the oil level after starting, when the

unit is at rated speed, and at normal operating temperature. If the oil level is high,

oil should be drained. If the dipstick shows low level, add new, clean oil.

Refer to Woodward manual 25071, Oils for Hydraulic Controls, for more

information on selection of oils for use in hydraulic actuators (governors). Proper

selection of the oil used in the actuator is necessary for the best governor

performance and maximum service life. The oil should have a minimum tendency

to foam or retain air, form sludge, or deposit varnish. It should protect actuator

parts from corrosion and not be detrimental to oil seals or paint.