Manual B03575.C UG40-DI Manual

Woodward i

Table of Contents

1. GENERAL INFORMATION......................................................................................................1

1.1 INTRODUCTION............................................................................................................................1

1.2 DESCRIPTION..............................................................................................................................1

1.3 SYSTEM COMPLIANCE .................................................................................................................1

1.4 GENERAL SAFETY PRECAUTIONS .................................................................................................1

1.5 NOTES, WARNINGS AND CAUTIONS..............................................................................................1

1.6 IDENTIFICATION PLATE.................................................................................................................2

1.7 TECHNICAL DATA ........................................................................................................................2

1.8 SOFTWARE VERSIONS .................................................................................................................2

2. ESD PROTECTION AND HANDLING.....................................................................................6

3. DESCRIPTION..........................................................................................................................7

3.1 INTRODUCTION............................................................................................................................7

3.2 DI CONTROL PANEL AND GOVERNOR DIAL PLATE.........................................................................7

3.3 MECHANICAL GOVERNOR.............................................................................................................7

3.3.1 Introduction...................................................................................................................7

3.3.2 Component description ................................................................................................7

3.3.3 Operation of the UG40-DI Mechanical Part .............................................................. 12

3.4 DIGITAL INTERFACE .................................................................................................................. 14

3.4.1 Introduction................................................................................................................ 14

3.4.2 Component Description............................................................................................. 15

3.4.3 Operation................................................................................................................... 15

4. INSTALLATION..................................................................................................................... 16

4.1 INTRODUCTION......................................................................................................................... 16

4.2 INSTALLATION REQUIREMENTS.................................................................................................. 16

4.3 UNPACKING.............................................................................................................................. 16

4.4 STORAGE................................................................................................................................. 16

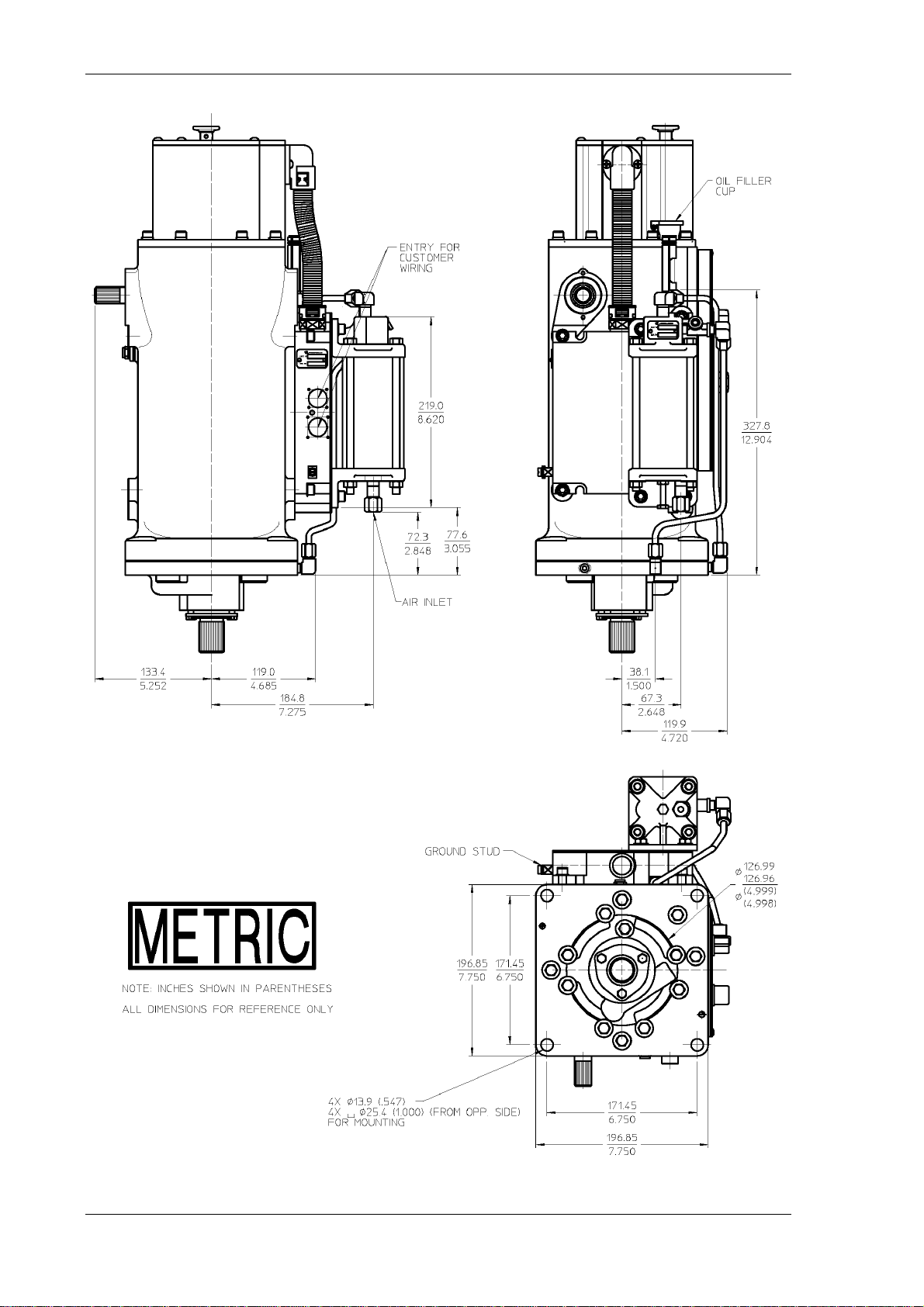

4.5 MOUNTING THE GOVERNOR ...................................................................................................... 16

4.6 LINKAGE ATTACHMENTS ........................................................................................................... 17

4.7 OIL SUPPLY ............................................................................................................................. 18

4.8 ELECTRICAL CONNECTIONS ...................................................................................................... 21

5. GOVERNOR MECHANICAL OPERATION AND ADJUSTMENTS ..................................... 22

5.1 INTRODUCTION......................................................................................................................... 22

5.2 CHECK THE MAXIMUM SPEED SETTING...................................................................................... 22

5.3 INITIAL OPERATION FOR A NEW GOVERNOR – MECHANICAL ....................................................... 22

5.3.1 Adjustments............................................................................................................... 22

5.3.2 Compensation Adjustments ...................................................................................... 22

5.4 READING SETTINGS FROM MECHANICAL GOVERNOR ON THE ENGINE.......................................... 24

5.4.1 Procedure.................................................................................................................. 24

6. CALIBRATION OF THE DIGITAL INTERFACE................................................................... 25

6.1 INTRODUCTION......................................................................................................................... 25

6.1.1 Calibration on test bench........................................................................................... 25

6.1.2 Calibration on engine ................................................................................................ 25

6.2 FUNCTIONS OF UG40-DI DURING CALIBRATION......................................................................... 25

6.2.1 Introduction................................................................................................................ 25

6.2.2 Explanation of the UG40-DI panel during calibration................................................ 25

6.3 CALIBRATION ON TEST BENCH .................................................................................................. 27

6.3.1 Procedure.................................................................................................................. 27

6.4 CALIBRATION ON ENGINE.......................................................................................................... 28

6.4.1 Procedure.................................................................................................................. 28

6.5 CALIBRATION FLOW CHART....................................................................................................... 28