Manual 37617B SPM-D2-10/YB - Synchronizing Unit

Page 4/51 © Woodward

Revision History

UL rating added to technical data / ambient variables for N & XN packages. See page 51.

Changed product name “SPM-D-xxx” to “SPM-D2-xxx”

Contents

Copyright And Disclaimer ......................................................................................................................... 3

Service And Warranty............................................................................................................................... 3

Intended Use............................................................................................................................................. 3

CHAPTER 2. GENERAL INFORMATION.........................................................................................7

CHAPTER 3. ELECTROSTATIC DISCHARGE AWARENESS .............................................................8

CHAPTER 4. INSTALLATION .......................................................................................................9

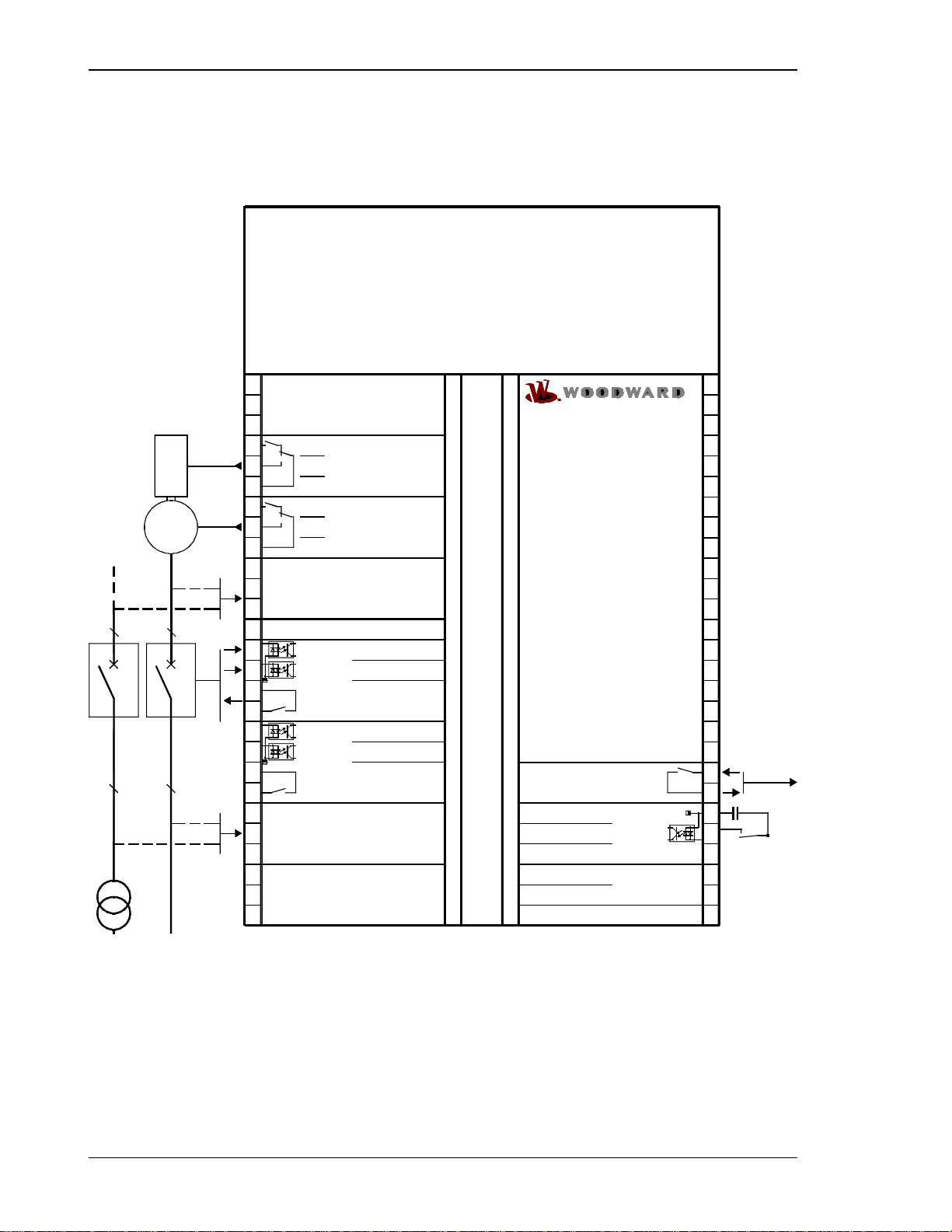

Wiring Diagram....................................................................................................................................... 10

SPM-D2-10/YB (24 Vdc) .............................................................................................................. 10

SPM-D2-10/NYB (90..250 Vac or 120…375 Vdc)........................................................................ 11

Reference Point...................................................................................................................................... 12

Power Supply.......................................................................................................................................... 12

Measuring Inputs .................................................................................................................................... 13

Mains/System U1 ......................................................................................................................... 13

Generator/System U2................................................................................................................... 13

Discrete Inputs........................................................................................................................................ 14

Relay Outputs......................................................................................................................................... 15

Controller Outputs................................................................................................................................... 15

CHAPTER 5. DESCRIPTION OF FUNCTIONS ...............................................................................16

Functionality............................................................................................................................................ 16

Table of Functions........................................................................................................................ 16

Control Inputs.......................................................................................................................................... 17

Isolation of the Power Supply from the Discrete Inputs.......................................................................... 17

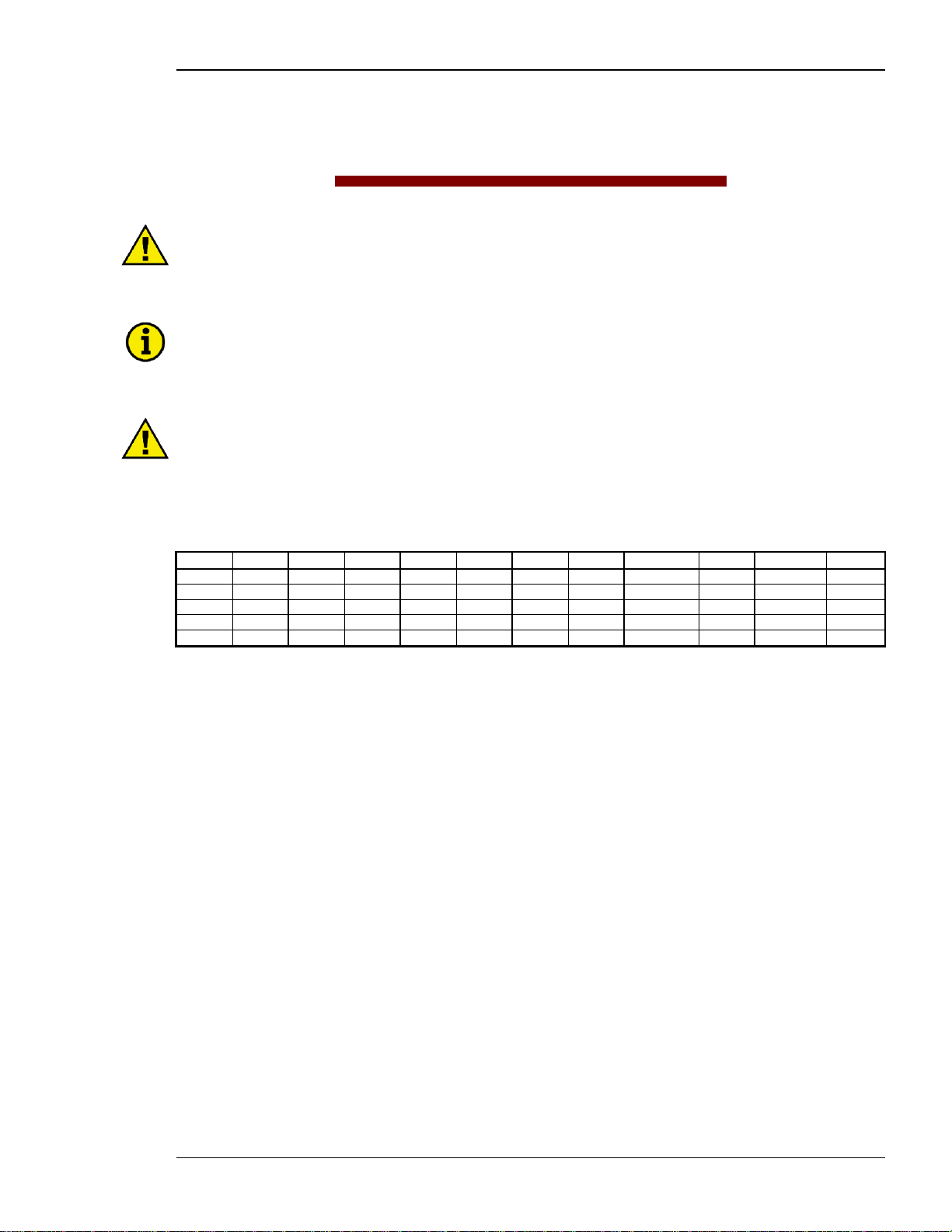

Operating Conditions.............................................................................................................................. 18

No Load Control ........................................................................................................................... 18

Synchronizing............................................................................................................................... 18

Dead Bus Start (Asynchronous Add-On)...................................................................................... 19

Synch-Check ................................................................................................................................ 19

Control Outputs....................................................................................................................................... 20

CHAPTER 6. DISPLAY AND OPERATING ELEMENTS ...................................................................21

Brief Explanation of the LEDs and Push Buttons ................................................................................... 22

LEDs............................................................................................................................................. 22

Buttons ......................................................................................................................................... 22

Others........................................................................................................................................... 22

LEDs....................................................................................................................................................... 23

Push Buttons........................................................................................................................................... 25

LC Display............................................................................................................................................... 26