2

Before you start the installaon of your kit, please read the following:

This kit is intended to be fied by someone who is competent and experienced at fing electric kits to

bikes. If you are not experienced and/or lack the necessary tools to complete any of the proceduresin

this manual, you should seek the advice of a professional who can fit the kit for you. If necessary, call us

on 01702 684444 or email us at support@wooshbikes.co.uk and we will try and put you in touch with

someone in your area that has the necessary experse to properly fit your kit. You will of course need to

pay for the technician to install your kit, these costs are not covered by Woosh Bikes.

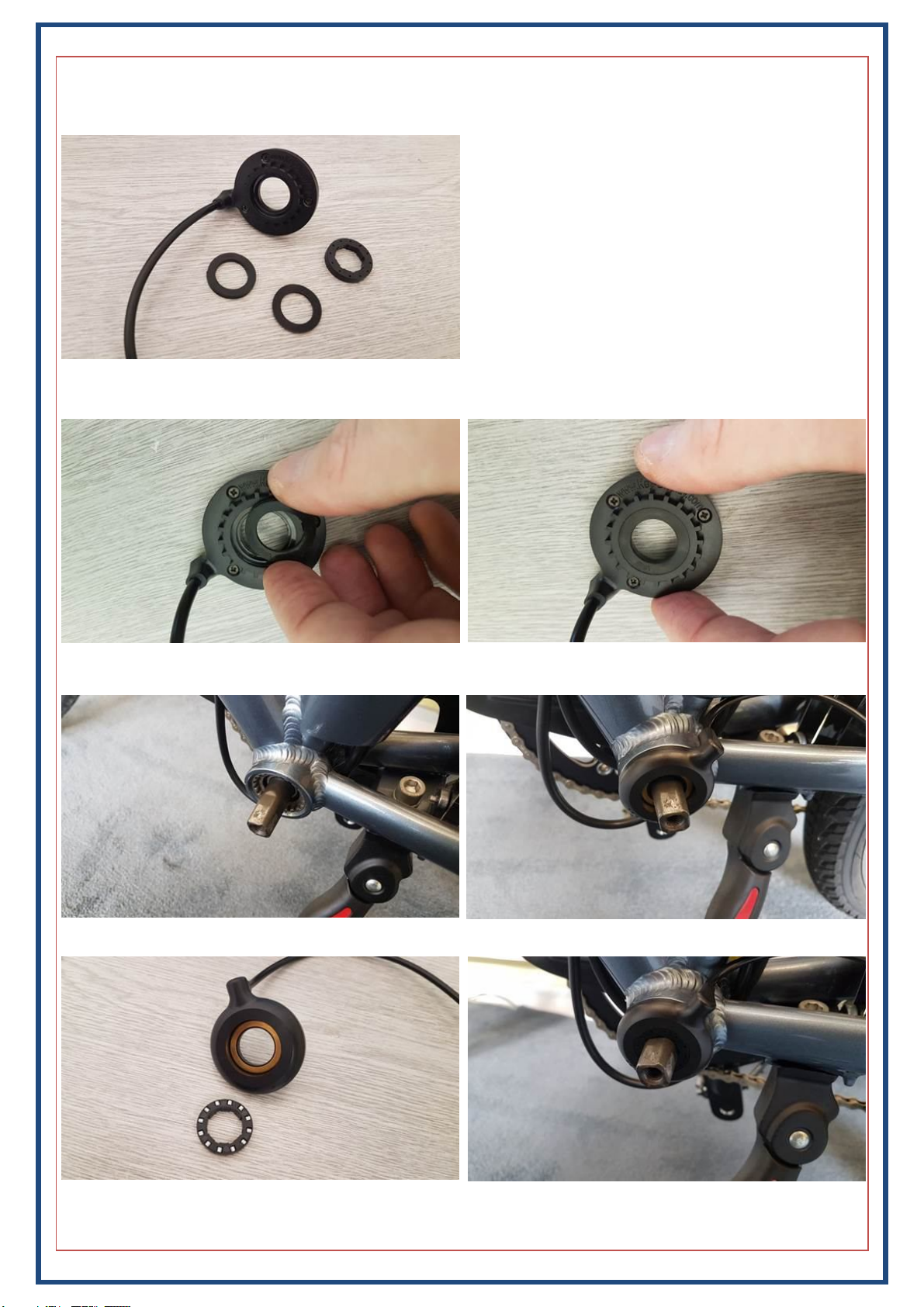

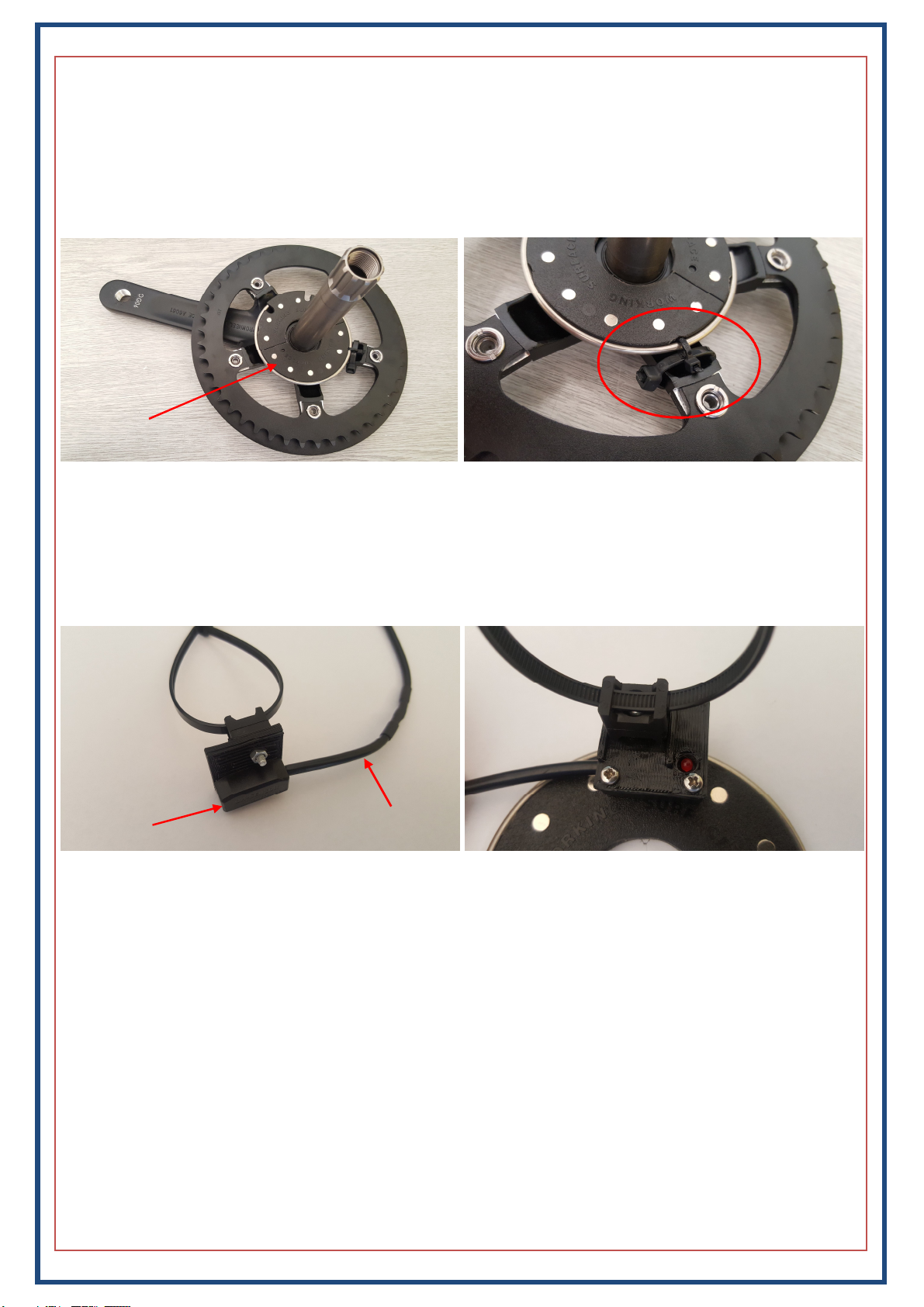

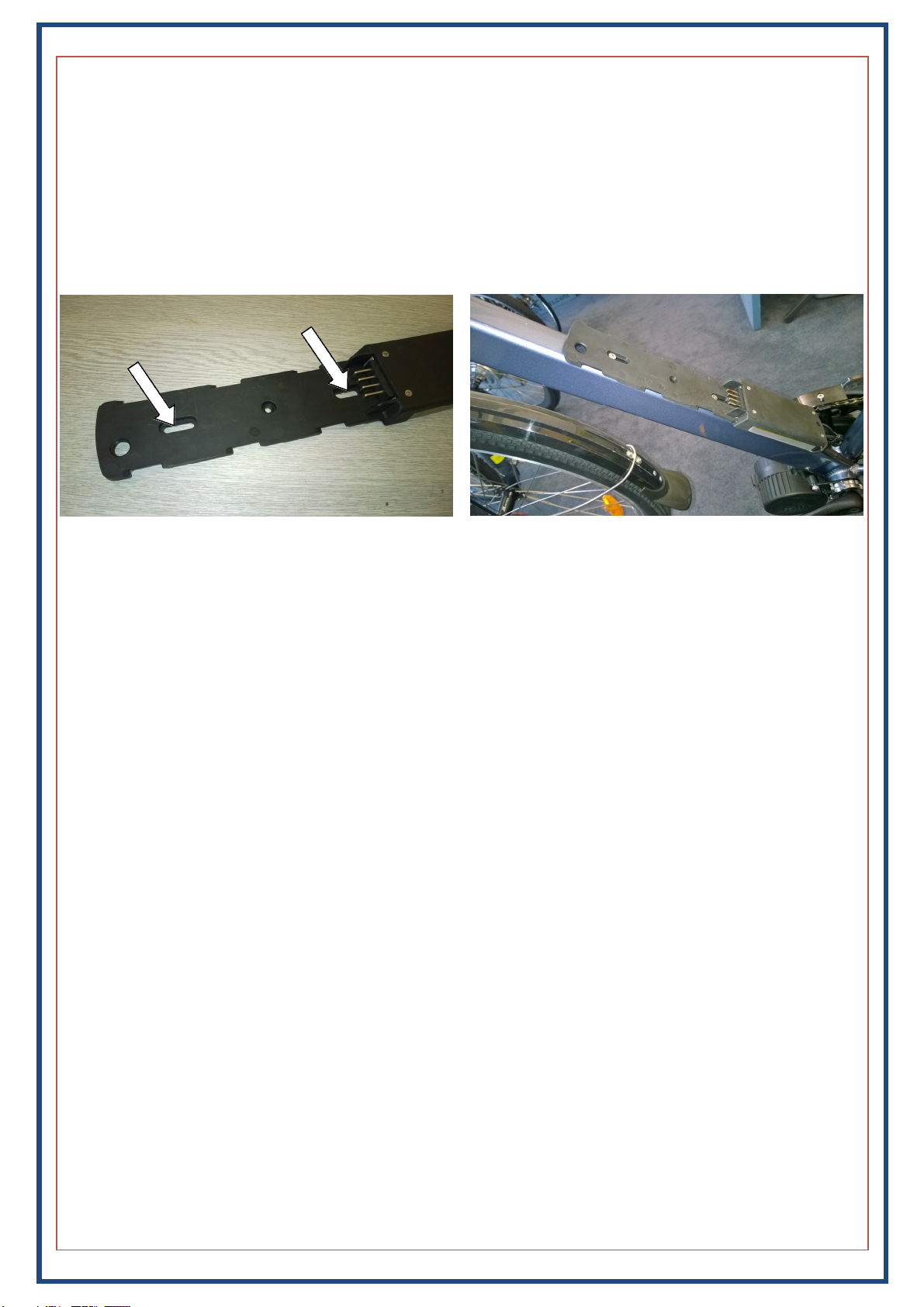

There are several different types of pedelec sensor, we would normally have determined which type is

suitable for your bike before you finalised your order. If we didn’t, please contact us before aempng

to fit your kit.

Warranty Terms:

If your kit is fied by a professional installer, it will be covered by our standard one year warranty, which

means that in the event of a failure, you would first need to have the person that installed your kit con-

firm the issue and likely cause, then you (or the installer) would need to contact us and provide us with

the details of the fault. If the issue cannot be resolved over the phone or via email, then you would need

to return the faulty part to us at your expense. We will then repair or replace the faulty part andsend it

back to you at our expense. If the kit was not fied by a professional and/or the failure that has occurred

is due to poor/incorrect installaon, or the kit has been used improperly, the warranty will be voided.