4

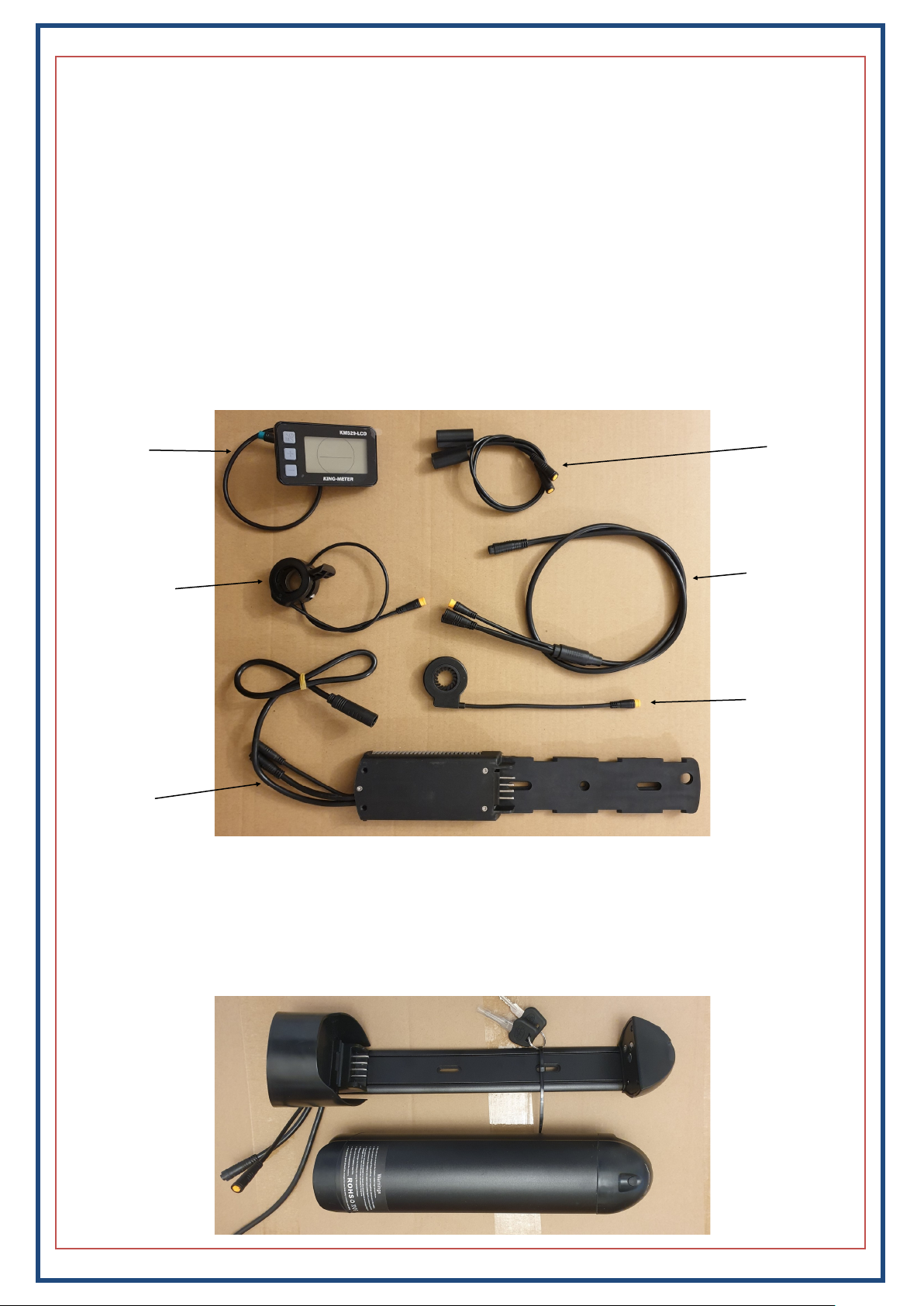

Installaon of the various Pedelec Assist Sensor (PAS) types

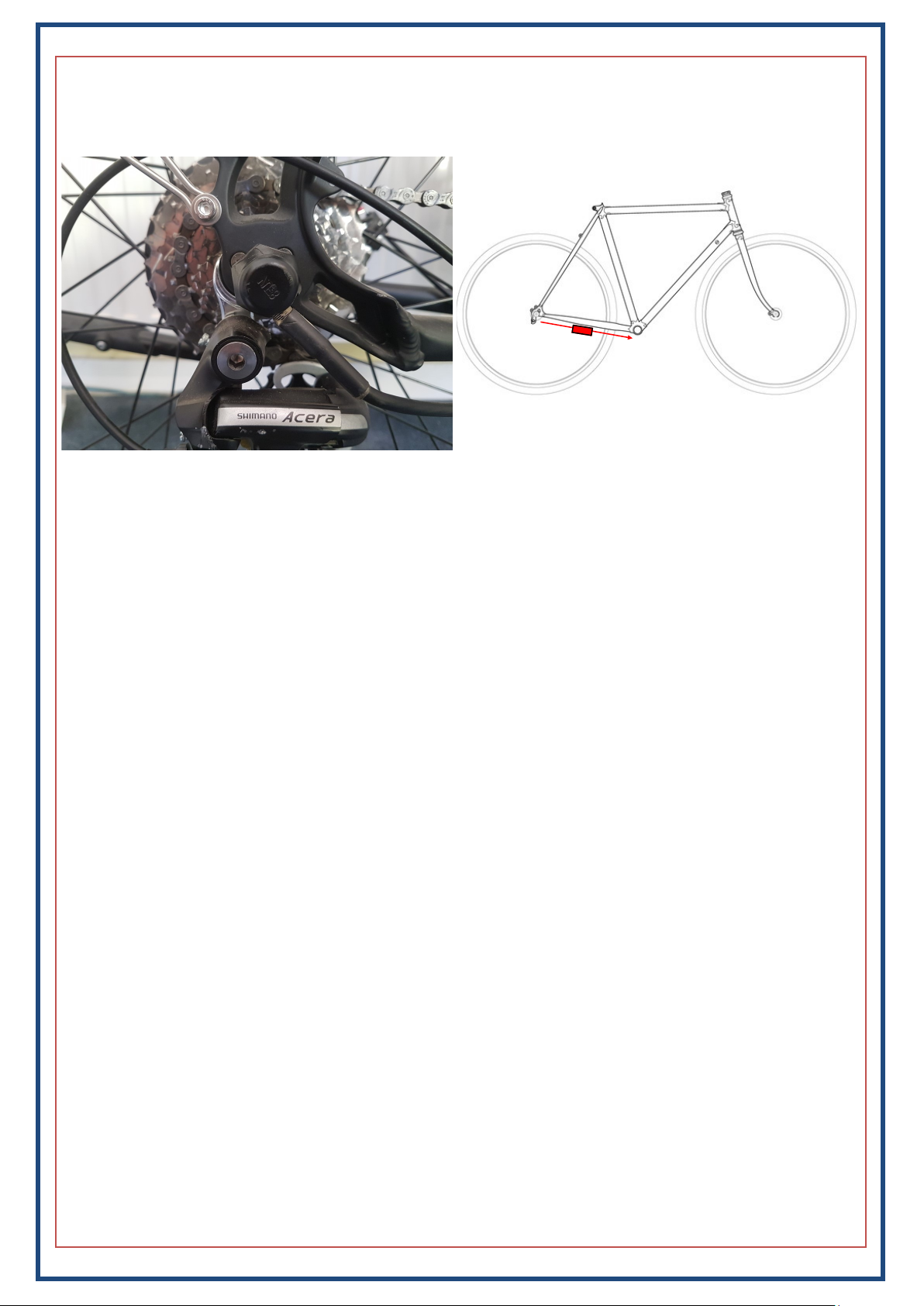

There are three types of PAS that can be used, two that t on the right side of the bike between the chain

-ring and frame, and the le-side sensor, which slots into the end of the boom bracket.

The right-side PAS kit consists of two parts, these are the sensor itself and the PAS disc. There are two

dierent opons for the disc/magnet-ring part of the PAS kit (see below-right), depending on whether

you have a square taper boom bracket or something else. In all cases, the sensor ring is mounted be-

hind the lip of the xed cup, or behind the right bearing shell (in the case of a BB with external bearings).

The PAS disc for square taper boom brackets is simply slid down the axle so that it is close to, but not

touching the sensor. For all other types of boom bracket, you would need to use the alternate disc

which comes in three parts—the two halves of the magnet ring, and the support/mounng plate. Ideally,

the mounng plate is cable-ed to the smallest chain ring (using the loops around the outside of the

plate), and the two halves of the magnet ring are then glued to the plate. In some cases, there is not al-

ways enough room to do this, and the ring needs to be bonded directly to the smallest chain ring and/or

you may need to use the seat-post mounted sensor instead—see next page.

Installaon Notes:

You need to ensure that the disc is the correct way around on the axle. The disc should be ed such that

the arrows on the disc are on the le side (facing the sensor). For other non-square taper boom

brackets, the two halves of the magnet ring only t on the mounng plate one way, so you can’t get it

wrong.

With external bearing shells, it is somemes necessary to t a spacer behind the shell, we can supply

these, but in many instances, you can just take one from the le side and move it over to the right.