2

The Freedom is the epitome of simple as it relates to screen prinng. It’s simple to set up, simple to operate, and simple to maintain. That

said, The Freedom does not limit you to simple designs or small jobs. This machine turns any manual press operator into a mass producing

printer. Freedom’s fast indexing speed, simple to use controls and precise micro registraon ensure that setups are as fast and easy as

with your manual press. Add our patented FlashBack to the Freedom and Workhorse has re-wrien the book on aordable high

producon while keeping it simple. Automang your manual shop gives you freedom from: long hours at the press, aching elbows and

wrists, late deliveries, high labor costs, and the list goes on.

Congratulaons on your purchase of

the Workhorse Products Javelin Pro

Automac Texle Prinng Press.

Check the crate for damage, DO NOT

accept the crate if damaged due to

improper handling during shipping.

Report any damage to the carrier at

once as well as Workhorse Products at

800-778-8779.

Inspect the crate contents

IMMEDIATELY while the carrier is sll

there. Our packaging has been

carefully designed to handle normal

shipping condions. However, we

cannot be responsible for damage by

the carrier. Upon rst sight of freight

damage nofy or point out to the

driver and le your claim with the

carrier, then nofy us.

Two year limited warranty

Micro processor controlled

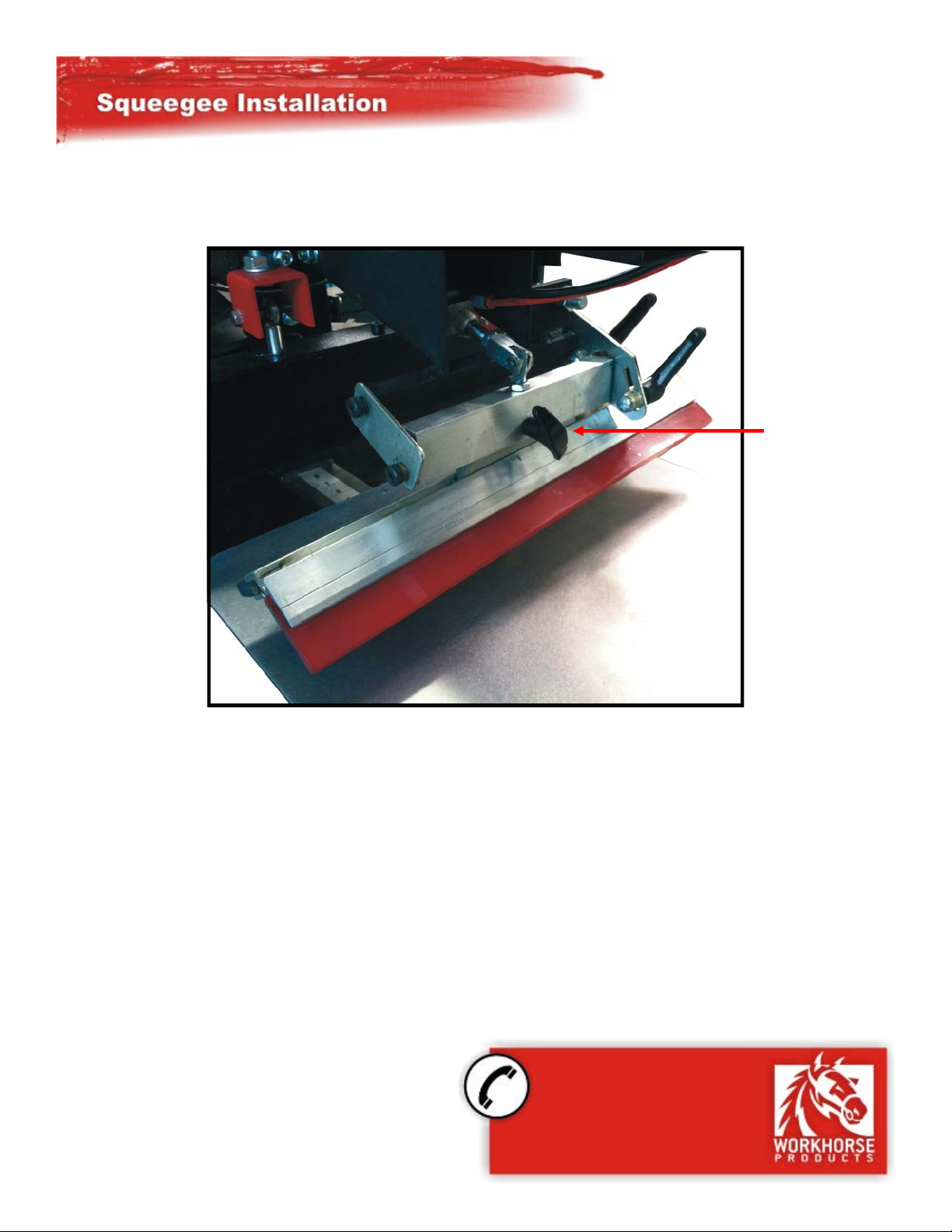

Fast, easy, squeegee and ood angle, pressure adjustments

Sing or double print strokes per screen for darker garments

Independent head controls

Non-warping solid aluminum platen

Adjustable rear screen clamp

Adjustable print stroke

Foot pedal

Features:

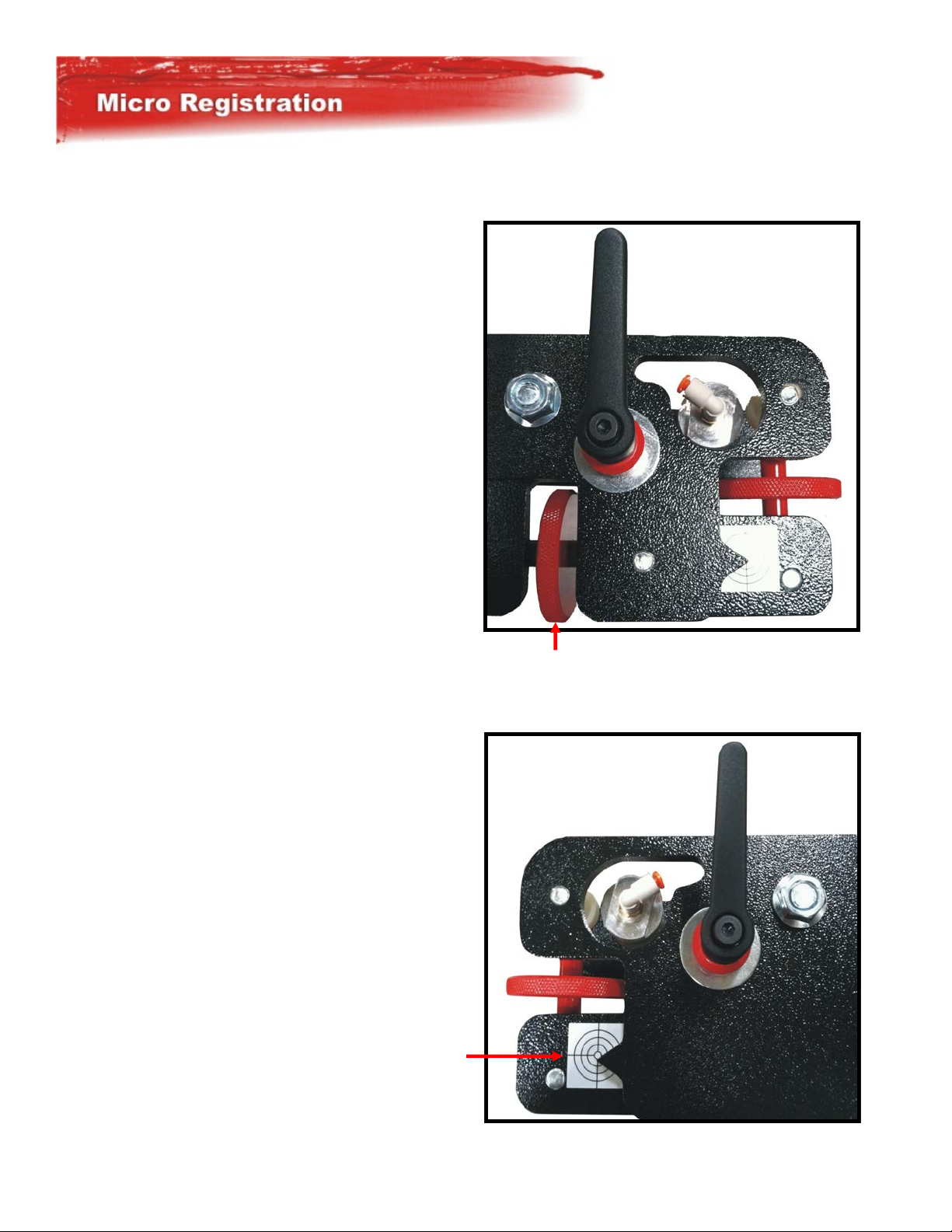

Micro registraon front & back for fast setups

heavy duty steel construcon throughout

Easily adjustable screen clamps

One knob quick change squeegee

Precision milled Registraon forks for exact registraon

Producon Counter

Variable o-contact adjustment

Easy release platens

60 doz./hr capability

Integrated safety system