INSTRUCTION MANUAL

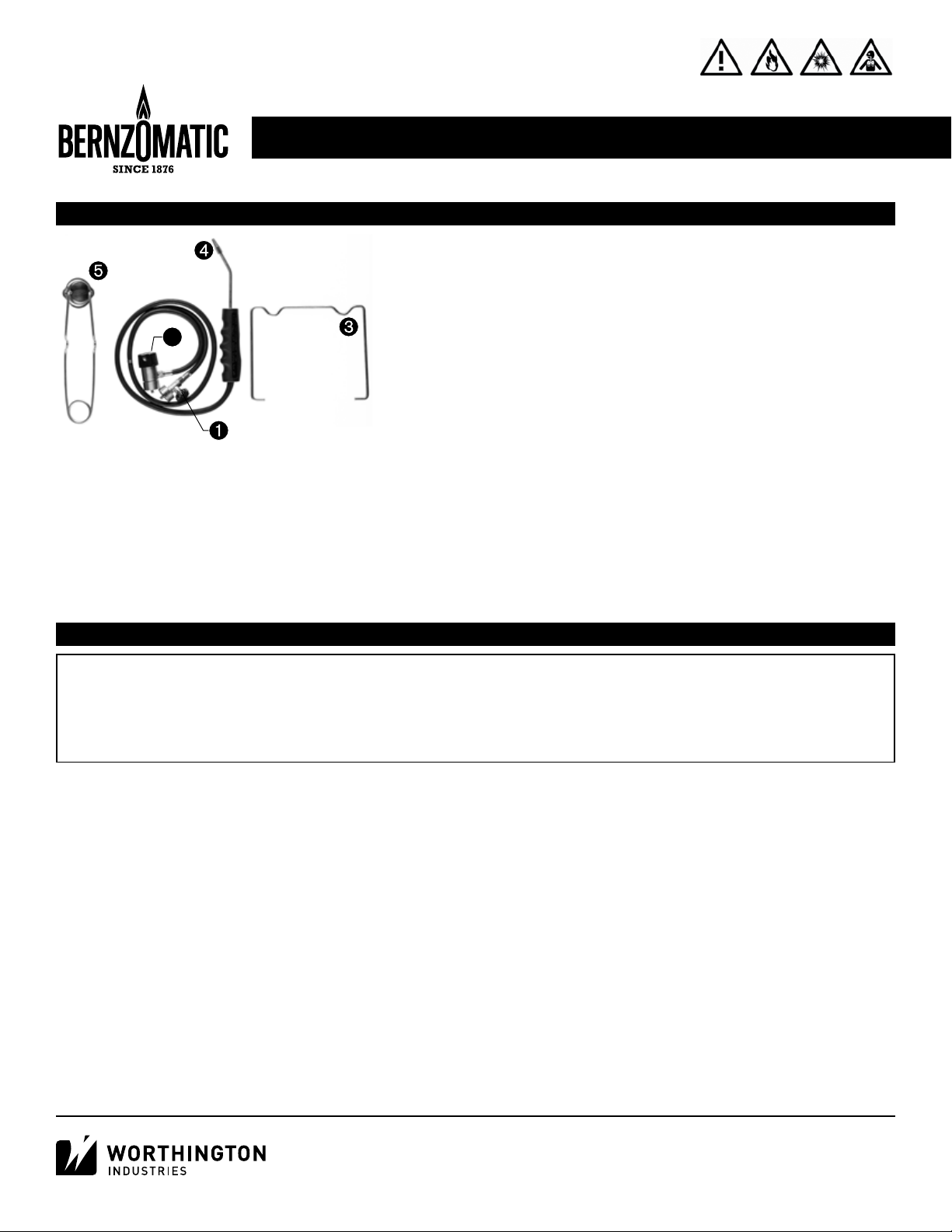

Trigger-Start Torches

Models: WK5500OX

DANGER

EXTREMELY FLAMMABLE GASES USED WITH TORCH.

FIRE/EXPLOSION HAZARD. CARBON MONOXIDE HAZARD

This oxygen brazing and cutting torch is unlike most hand held torches.

It is designed to be used simultaneously with an oxygen cylinder and a

MAP-Pro™ or propane cylinder. The use of an oxygen cylinder results in

the torch flame burning at much higher temperatures as it would without an

oxygen cylinder. Do not use this torch until you become thoroughly familiar

with its proper use and potential hazards. In particular, you must not attempt

to ignite the torch while oxygen is flowing to the torch. Further, when turning

the torch off ALWAYS TURN OFF THE OXYGEN BEFORE TURNING OFF THE FUEL GAS. Turning off the fuel gas while oxygen is still

flowing could result in a flash back and an explosion.

Read and follow the instructions and warnings in this manual. Familiarize yourself with the torch before lighting and using.

Review instructions and warnings periodically to maintain awareness. Do not try to operate before reading instructions and

without being thoroughly familiar with this torch’s use and potential hazards.

Failure to comply with these instructions and warnings may result in damage to property, serious personal injury, or death.

WARNING

• While the Oxygen-MAP-Pro™Torch is not a commercial oxygen torch, it produces flame temperatures up to 5300°F.

This is much hotter than the flame of a standard propane torch. These extremely high temperatures can cause serious

personal injury or damage to the metal you are working on if not handled carefully and correctly.

• Never point the torch toward the cylinders or let the flame deflect to heat the cylinder in any manner.

• Do not permit grease or oil to be placed on or come in contact with any portion of the torch, hoses or cylinders,

particularly the oxygen cylinder, oxygen connection, oxygen regulator or oxygen hose as oxygen can cause the grease

or oil to burn in an uncontrolled manner.

• Keep torch out of reach of children and anyone who has not read instructions. Do not point torch towards face, other

persons or flammable objects. Never attempt to use torch as a cigarette lighter.

• Disconnect cylinders when not in use.

Materials used in the construction of this device may contain brass (which may contain lead), a chemical known to the

State of California to cause birth defects or other reproductive harm.

Combustion by-products produced when using this device contain chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

ENG DANGER INCENDIE EXPLOSION FUMES

1

1

1

1

1