8 9X GLOO®•Windeckstr. 4 •83250 Marquartstein •Germany Phone: +49 (0) 8641 6948 - 60 •xgloo.com •info@xgloo.com

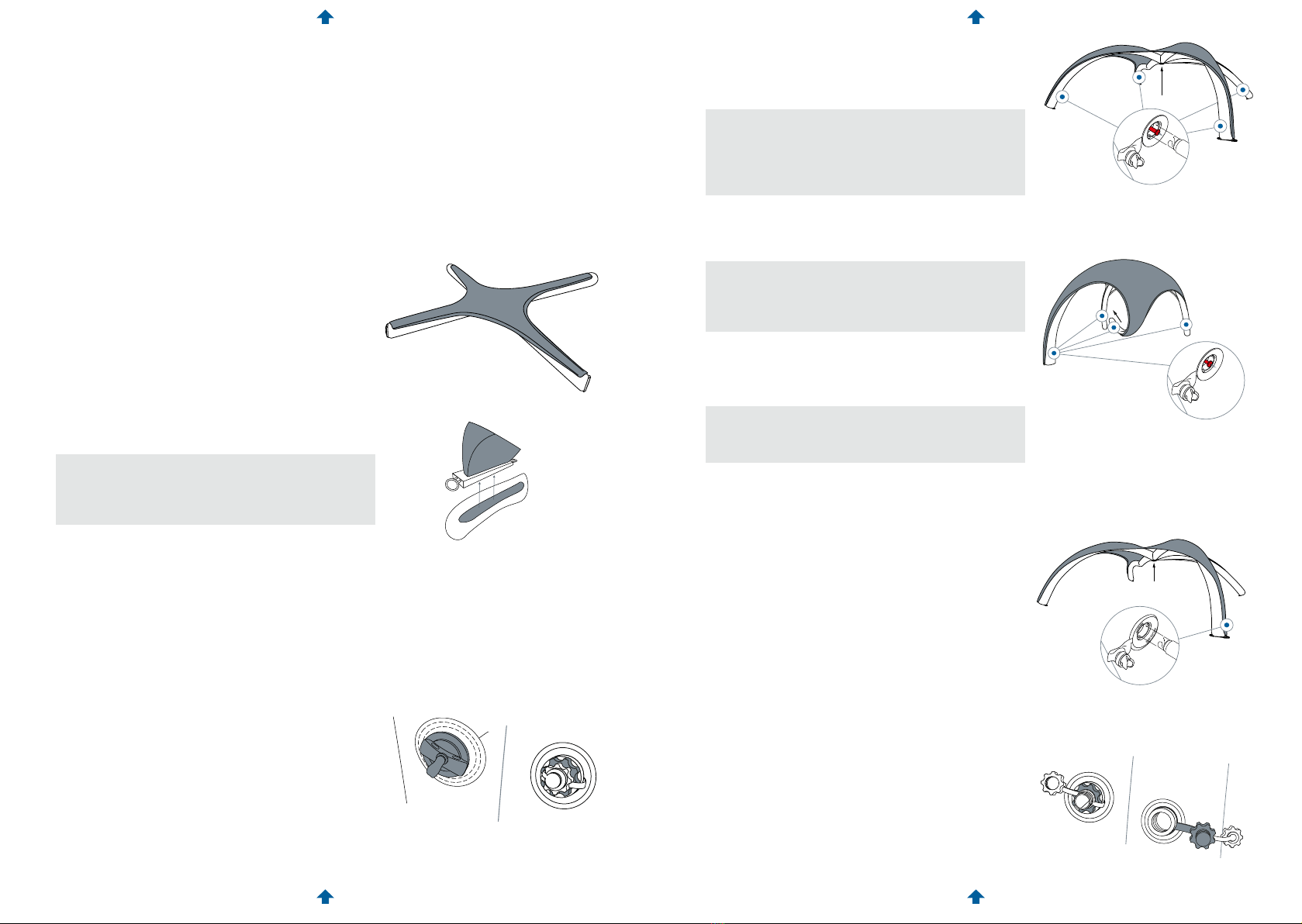

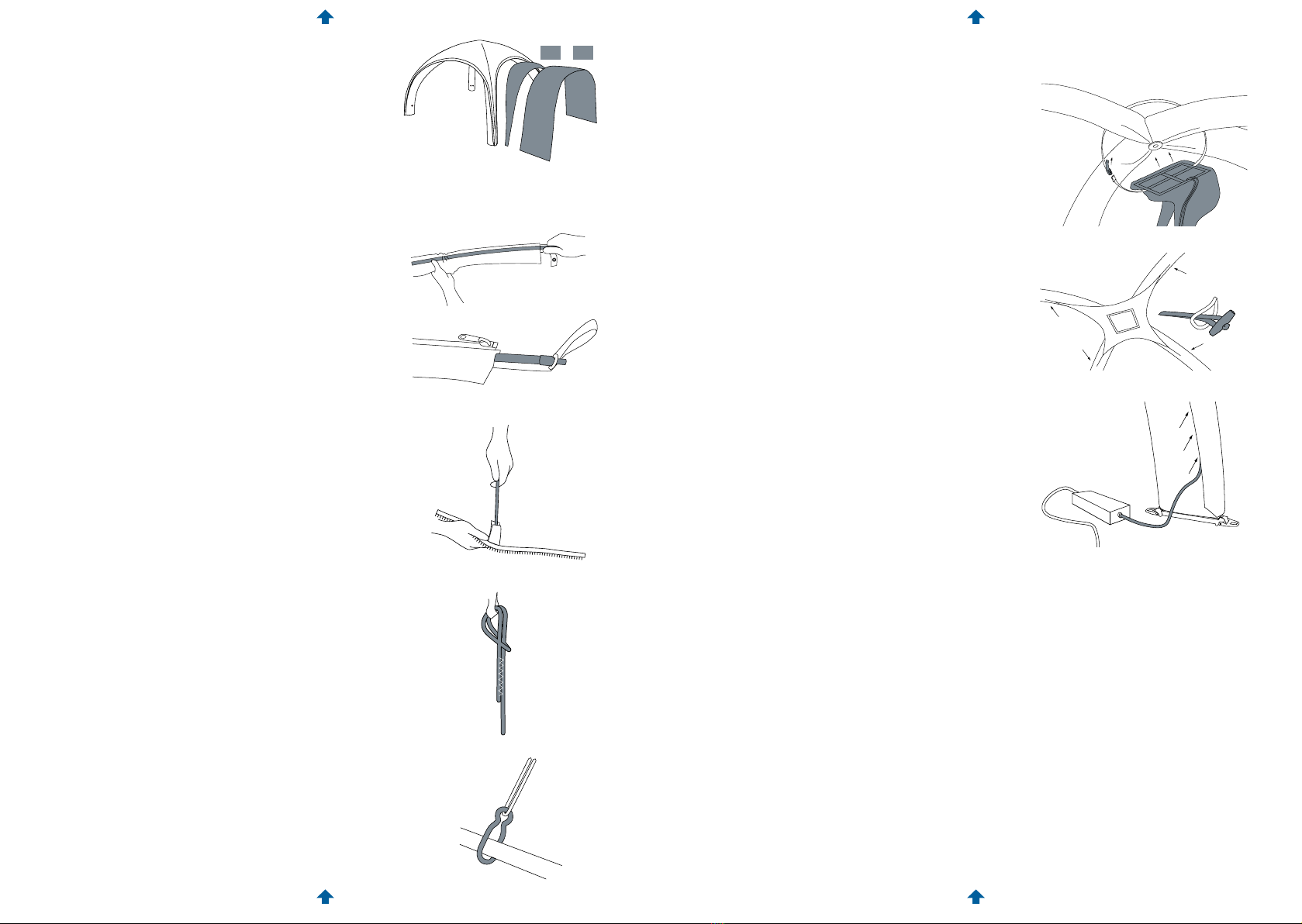

3.3 PUMPS

3.3.1. INFLATION WITH THE ELECTRIC PUMP

Screw the threaded end of the supplied hose onto the

discharge opening of the pump.

Plug the power cable into an electric socket. Note that

the Bravo 2000 has a booster that has to be activated

using the switch on the pump. Please also observe the

instructions and information supplied with the electric

pump.

3.3.2. INFLATION WITH THE HAND PUMP

The hand pump included in the contents of delivery is

equipped with various adapters that allow connection

to dierent valves. The hose should not be kinked or

compressed as this could result in leaks or breakage!

NOTE FOR INFLATING THE CANOPY: Two pump hoses are

always included with delivery. These can be connected so

that the canopy valves can be reached for inflation.

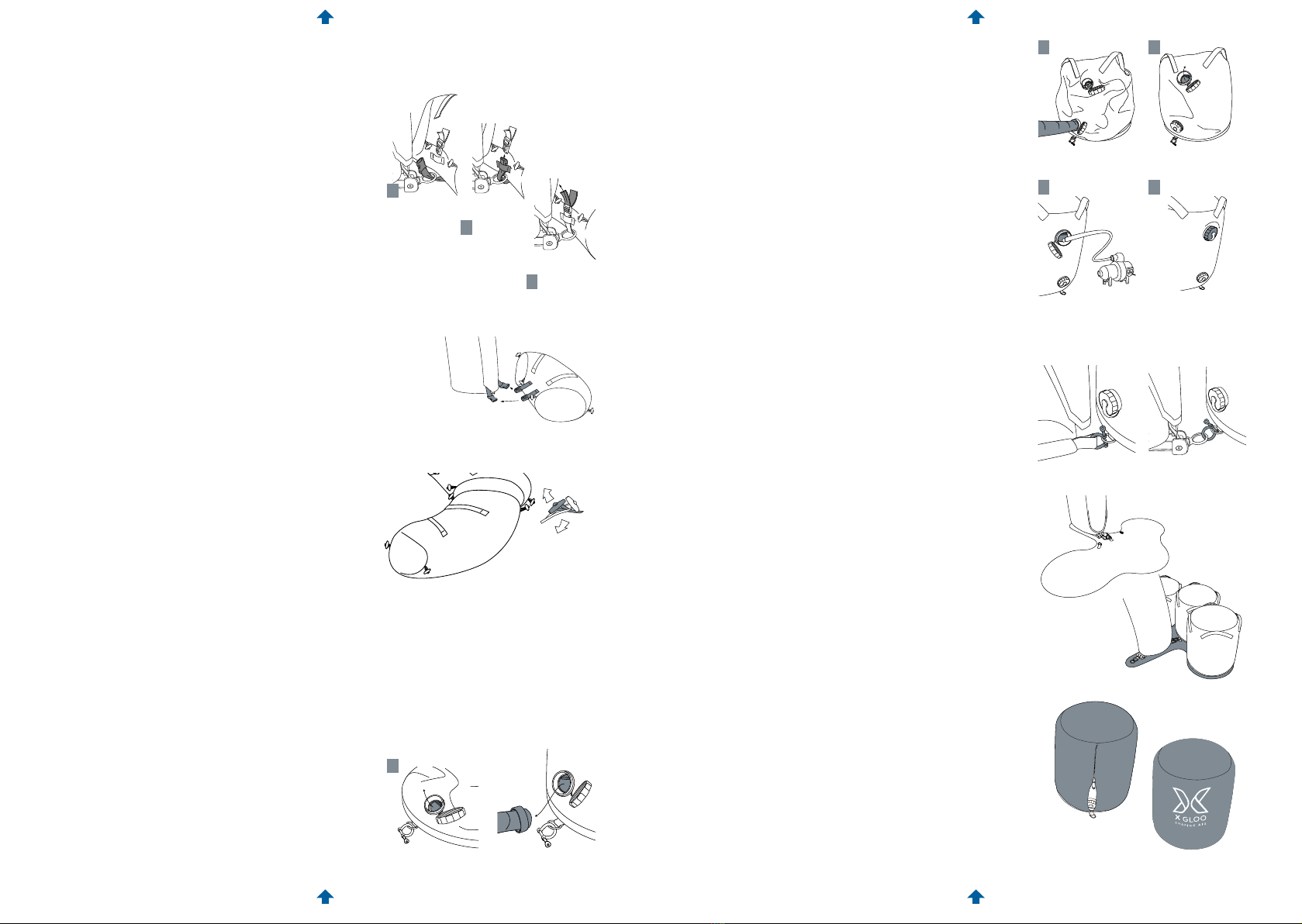

NOTE WHEN FILLING WITH COMPRESSED AIR:

XD 4: Assembley by only one person and corresponding

compressed air bottle in approx. 90 seconds. XD 5: Assem-

bley by only one person and with compressed air (compres-

sor - without lubricator and with pressure reducer or two

bottles) Alternatively an electric pump (Bravo 2000) can be

used. For longer operations, it is advisable to bring the tent

up to the recommended maximum operating pressure du-

ring the course of the operation. This usually requires only a

few strokes with the manual pump and can be done at any

time later. For the XD 5 - 300 mbar / for the XD 4 - 400.

pressure in the tube has been reachedThe overpressure

valve prevents the tube from bursting if the air pressure

inside is too high, and because it is a safety-related

part, special attention should be given to it.

Before inflation, every overpressure valve should be

checked to ensure that it is functioning properly. To do

this, unscrew the valve housing from the socket and

check to make sure that the spring can be pressed in.

Make sure that the valve is properly screwed closed

again after testing.

Sand or dirt can jam the spring and valve, which may

prevent the valve from functioning correctly.

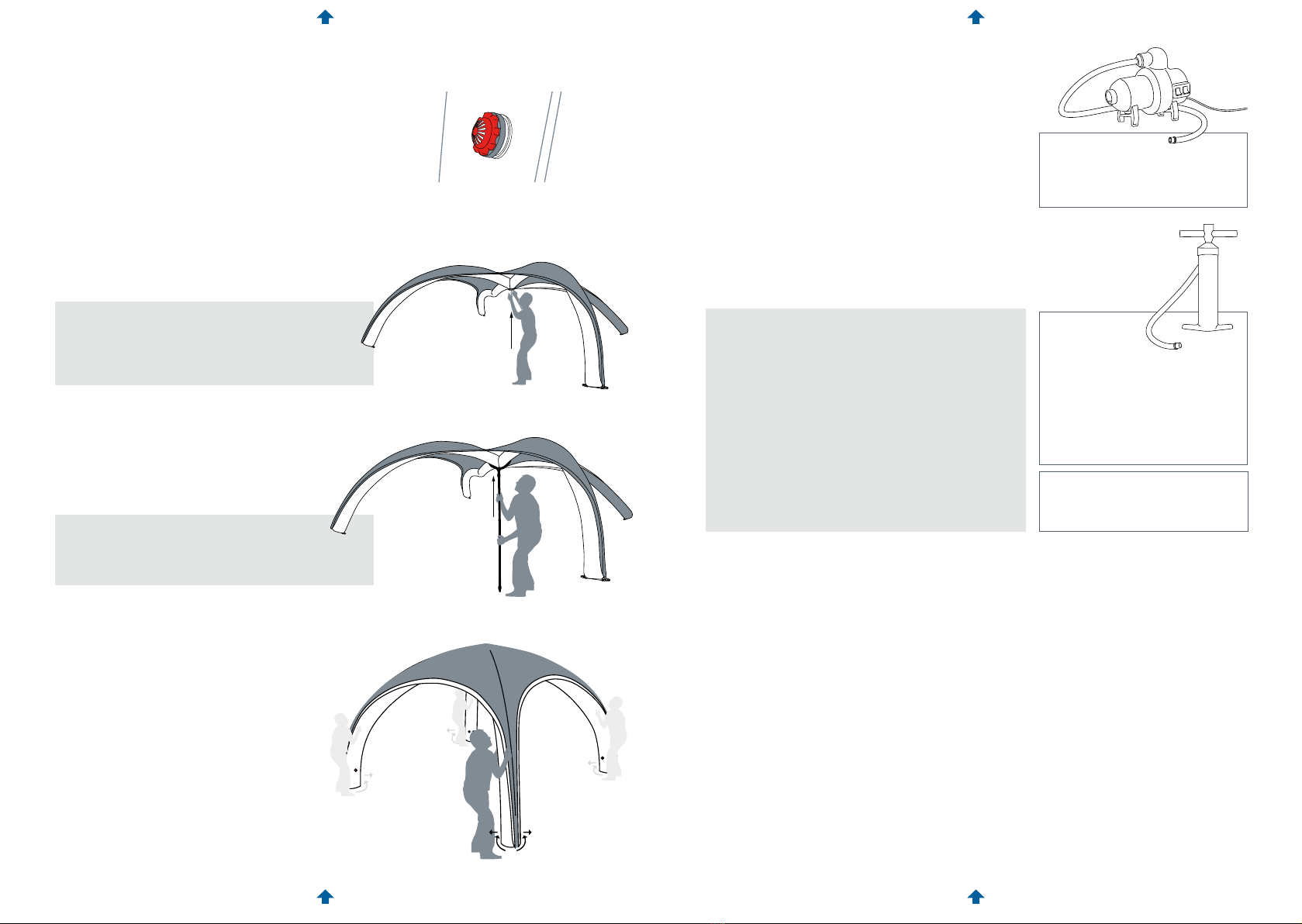

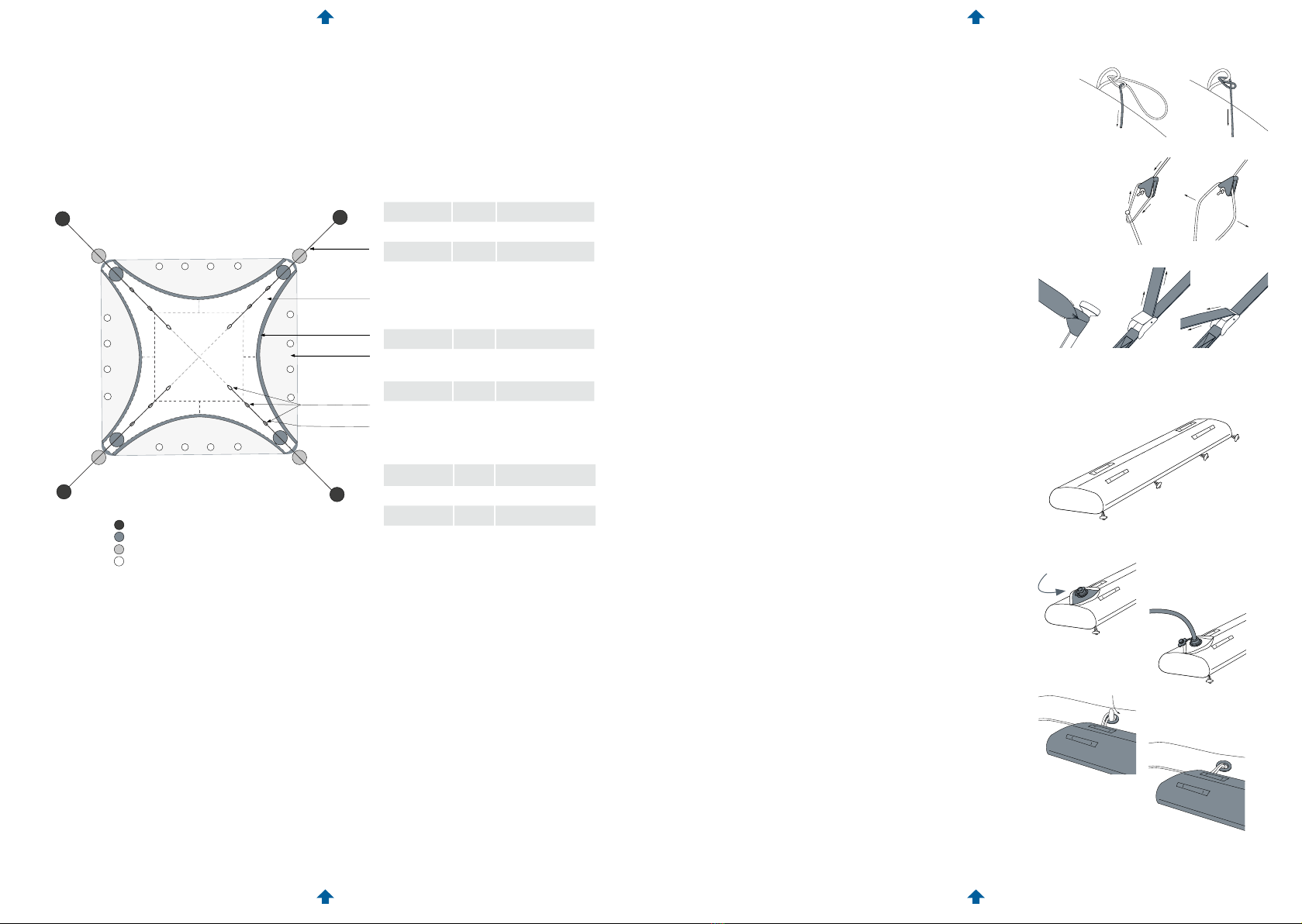

3.2.4 RAISING: XC 3 | XD 4/5/6/7

PLEASE NOTE: Raising the tent from the ground requires

some assistance. Before the tubes are fully inflated, the

middle of the tent — where the tubes intersect — must

be actively lifted o the floor. This prevents the tent from

possibly being damaged from being inflated invertedly.

When setting up the tent in sandy terrain, make sure

that no grains of sand get into the hoses or pumps

through valve openings, which could lead to damage

or leaks.

PLEASE NOTE: The specified maximum air pressure

must not be exceeded and is reached when the

overpressure valves open and the excess air beings to

escape.

For the tent to appear optically perfect, the tubes

should be aligned by hand after inflation and the roof

readjusted on the tubes if necessary.

TIP: Note the

valve plug

at the top of the pump body::

OPEN = pumps only on the

down stroke

(Single Action)

CLOSED = pumps on both the

up and down stroke

(Double Action)

See the notation

on the hose connection::

OUT = inflate

IN = deflate

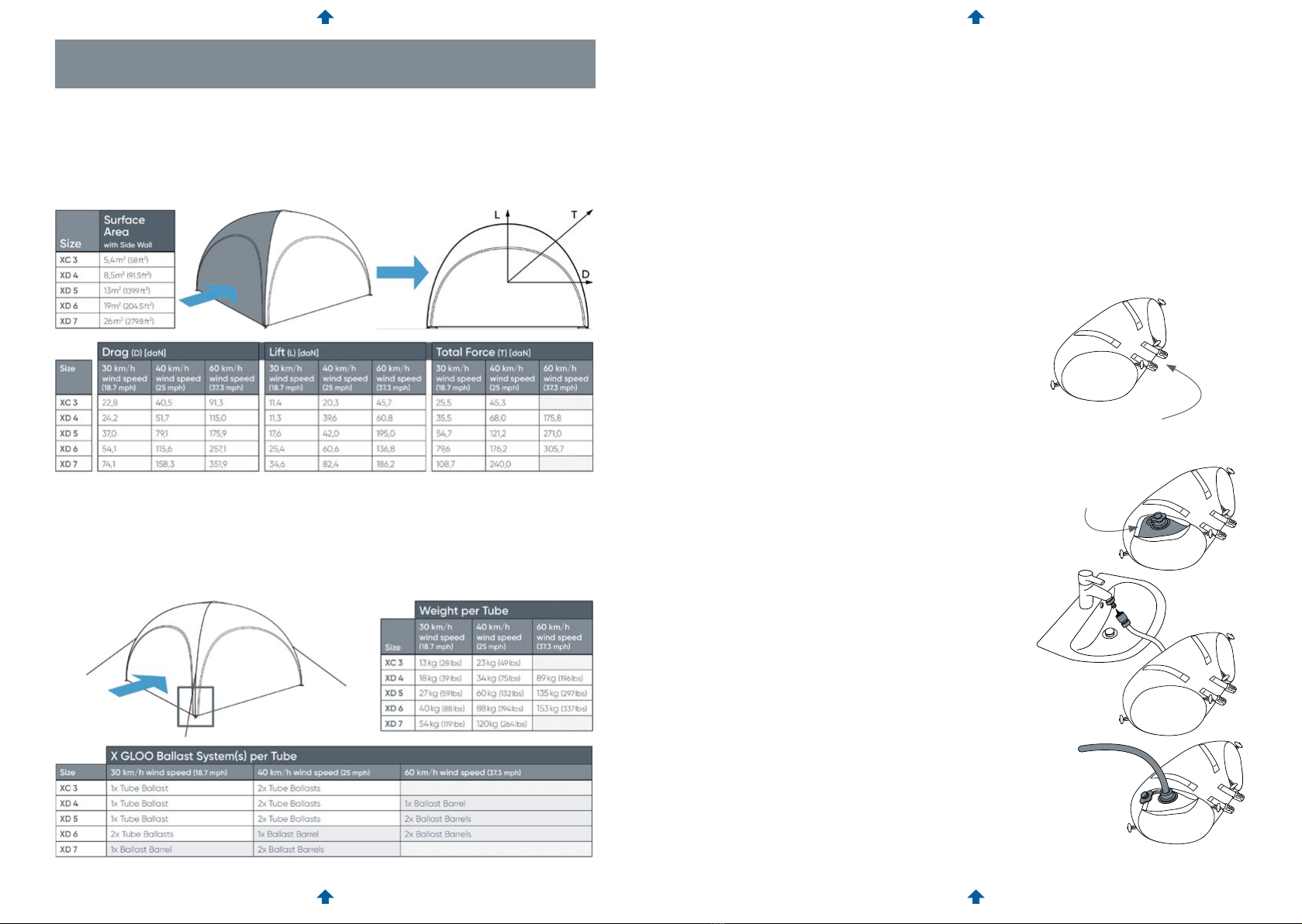

4. ANCHORING

The X GLOO XD and the XC series have been developed to be mobile and modular

lightweight tents. Despite their low weight, and the associated relatively low risk potential, the

following information must be read before use and diligently observed to prevent damage to

property and personal injury.

GENERAL INSTRUCTIONS

Depending on the nature of the terrain, the appropriate anchoring accessories must be used:

• On firm, packed soil, the X GLOO Anchoring Set (tent stakes) for the appropriate tent size

can be used.

• On snow or sand, the Snow Anchors or Sand Anchors are to be used in place of tent stakes,

respectively.

• On asphalt and similar hard surfaces, the tent must be weighted down using ballasts

sucient for the tent size and maximum expected wind speed.

The table in the wind speed certificate on the next page shows the type and quantity of

ballasts to be used, depending on the expected maximum wind speed and the tent size.

XD 4/5/6

XD 7

Observe this note when using the

compressed air cylinder in the X GLOO

tent series XD PROTECT.