PAGE 6

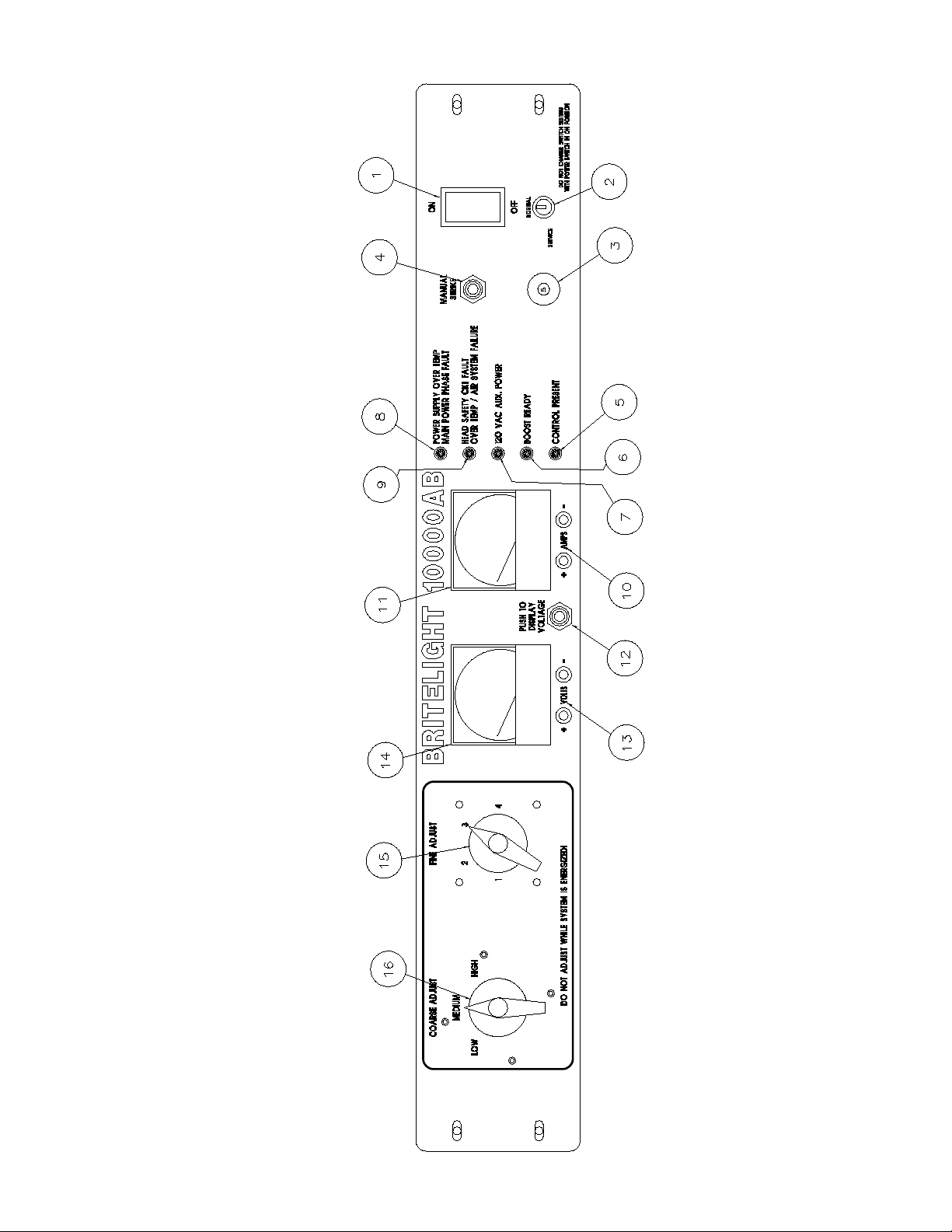

BL10000AR CONTROL PANEL & SYSTEM OPERATION

1. MAIN POWER SWITCH

USED TO MANUALLY CONTROL THE SYSTEM OPERATION. WHEN THE NORMAL / SERVICE SELECTOR SWITCH IS

IN THE NORMAL POSITION THE MAIN POWER SWITCH WILL PREVENT THE SYSTEM FROM ENERGIZING WHEN THE

CONTROL POWER CIRCUIT TURNS ON. WHEN THE NORMAL / SERVICE SELECTOR SWITCH IS IN THE SERVICE

POSITION THE MAIN POWER SWITCH ACTS AS A NORMAL POWER SWITCH TURNING THE SYSTEM BOTH ON

AND OFF.

2. NORMAL / SERVICE SELECTOR SWITCH

USED TO SELECT THE MODE OF OPERATION FOR THE SYSTEM. WHEN THIS SWITCH IS IN THE NORMAL POSITION

THE SYSTEM IS ENERGIZED AND DE-ENERGIZED BY THE REMOTE CONTROL CIRCUIT. WHEN THIS SWITCH IS IN

THE SERVICE POSITION THE SYSTEM GENERATES IT'S CONTROL POWER INTERNALLY FROM THE 230 VOLT MAIN

SERVICE SO THE SYSTEM CAN BE OPERATED AS AN INDEPENDENT UNIT WITHOUT THE REMOTE CONTROL

CIRCUIT ENERGIZED.

3. CIRCUIT BREAKER CB2

THIS CIRCUIT BREAKER PROTECTS THE REMOTE CONTROL POWER CIRCUIT OUTPUT AND THE 120VAC

AUXILIARY POWER SOURCE FROM OVERLOADS AND SHORT CIRCUITS.

4. MANUAL STRIKE SWITCH

THIS SWITCH IS NOT NORMALLY USED. IT HAS BEEN INSTALLED AS A TROUBLE SHOOTING AID. THIS SWITCH IS

WIRED IN PARALLEL WITH THE AUTO STRIKE RELAY CIRCUIT. IF A SYSTEM DOES NOT STRIKE AUTOMATICALLY

THIS SWITCH WILL ENERGIZE THE IGNITOR CIRCUIT IN THE LAMP HEAD. IF THE IGNITOR IN THE HEAD FIRES WHEN

THIS SWITCH IS DEPRESSED THE IGNITOR CIRCUIT IN THE HEAD IS IN OPERATING ORDER. IF THE IGNITOR WORKS

AND THE LAMP LIGHTS THEN THE AUTO STRIKE CIRCUIT SHOULD BE CHECKED. IF THE LAMP DOES NOT LIGHT

WHEN THE IGNITOR FIRES THEN THE TROUBLE MAY BE IN THE POWER SUPPLY OR LAMP HEAD.

5. CONTROL READY INDICATOR

MONITORS THE VOLTAGE ON THE CIRCUIT THAT CONTROLS THE OPERATION OF THE SYSTEM. THIS INDICATOR

WILL LIGHT WHENEVER CONTROL POWER IS AVAILABLE AT THE LINE SIDE OF THE MAIN POWER SWITCH. THIS

CONDITION WILL EXIST WHEN THE SYSTEM IS IN THE NORMAL OPERATING MODE AND THE REMOTE CONTROL

SWITCH CIRCUIT IS CLOSED AND WHEN THE SYSTEM IS OPERATING IN THE SERVICE MODE.

6. BOOST READY INDICATOR

MONITORS THE OUTPUT OF THE BALLAST AND LIGHTS WHENEVER THE OUTPUT VOLTAGE IS OVER 100 VDC.

WHEN THIS INDICATOR LIGHTS THE OUTPUT OF THE BALLAST IS AT A VOLTAGE SUFFICIENT TO IGNITE THE LAMP.

UNDER NORMAL OPERATING CONDITIONS THIS INDICATOR WILL LIGHT FOR A MOMENT JUST BEFORE THE

AUTO STRIKE CIRCUIT IGNITES THE LAMP. IF THE SYSTEM DOES NOT AUTO STRIKE AND THIS LAMP IS LIT CHECK

THE AUTO STRIKE AND IGNITOR CIRCUITS. IF THE SYSTEM DOES NOT AUTO STRIKE AND THIS LAMP IS NOT LIT

CHECK THE BALLAST CORE.

7. 120 VAC AUXILIARY POWER INDICATOR

INDICATES THE OPERATION OF THE INTERNAL 120 VOLT POWER CIRCUIT WHEN THIS INDICATOR IS LIT THE

CIRCUIT IS OPERATING.

8. POWER SUPPLY OVER TEMP / MAIN POWER PHASE FAULT INDICATOR.

THIS INDICATOR WILL LIGHT IF THE FOLLOWING CONDITIONS EXIST IN THE BALLAST SECTION OF THE SYSTEM. IF

THE POWER SUPPLY FAULT INDICATOR IS LIT THE BALLAST CORE IS OVER SAFE OPERATING TEMPERATURE OR

THE PHASE LOSS CIRCUIT BREAKER HAS TRIPPED. CHECK THE HEAT SINK AND EXHAUST COOLING FAN

OPERATION. IF THE PHASE LOSS CIRCUIT BREAKER IS TRIPPED CHECK THE INPUT POWER FOR A MISSING PHASE

OR LINE IMBALANCE. WHEN THE PROBLEM IS CORRECTED THIS INDICATOR WILL EXTINGUISH AND THE SYSTEM

WILL GO INTO NORMAL OPERATION.