5

SAFETY NOTICE............................................................................................................................8

1. SUMMARIZATION.....................................................................................................................9

1-1. Product summarization......................................................................................................9

1-2. Specs................................................................................................................................11

1-3. Parts explanation..............................................................................................................13

1-4. Outline dimension............................................................................................................15

2. IN-OUT SPECS AND EXTERIOR LAYOUT...........................................................................17

2-1. Input specs.......................................................................................................................17

2-2. Relay output specs and circuit.........................................................................................19

2-3. Transistor output specs and circuit...................................................................................21

3. PLC FUNCTION AND APPLICATION....................................................................................23

3-1. PLC instruction................................................................................................................23

3-2. soft component range.......................................................................................................24

3-3. Set up a project ................................................................................................................28

3-4. communication function..................................................................................................31

4. HMI FUNCTION AND APPLICATION....................................................................................35

4-1. HMI function introduction...............................................................................................35

4-2. Build a project..................................................................................................................36

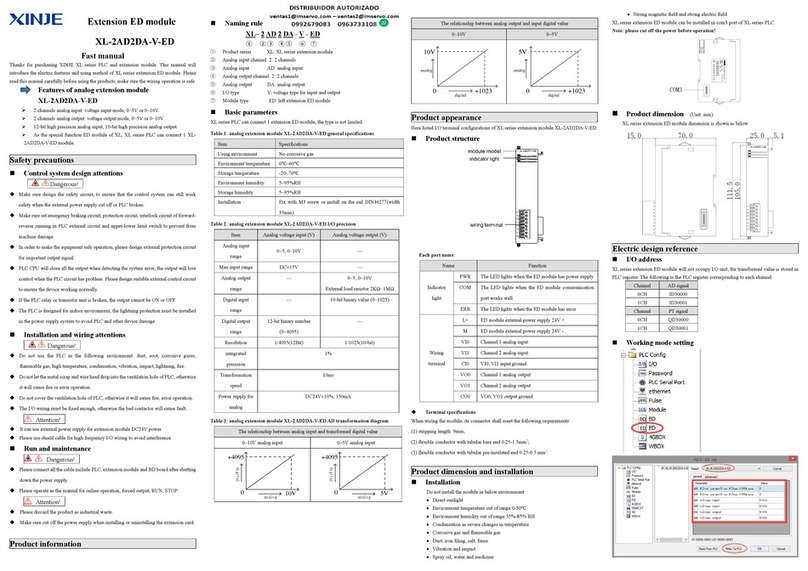

5. THE EXTENSION ABILITY OF XP/XMP...........................................................................39

5-1. extend BD board..............................................................................................................39

5-2. extend MA model ............................................................................................................42

5-3. Other extension................................................................................................................45

Catalog