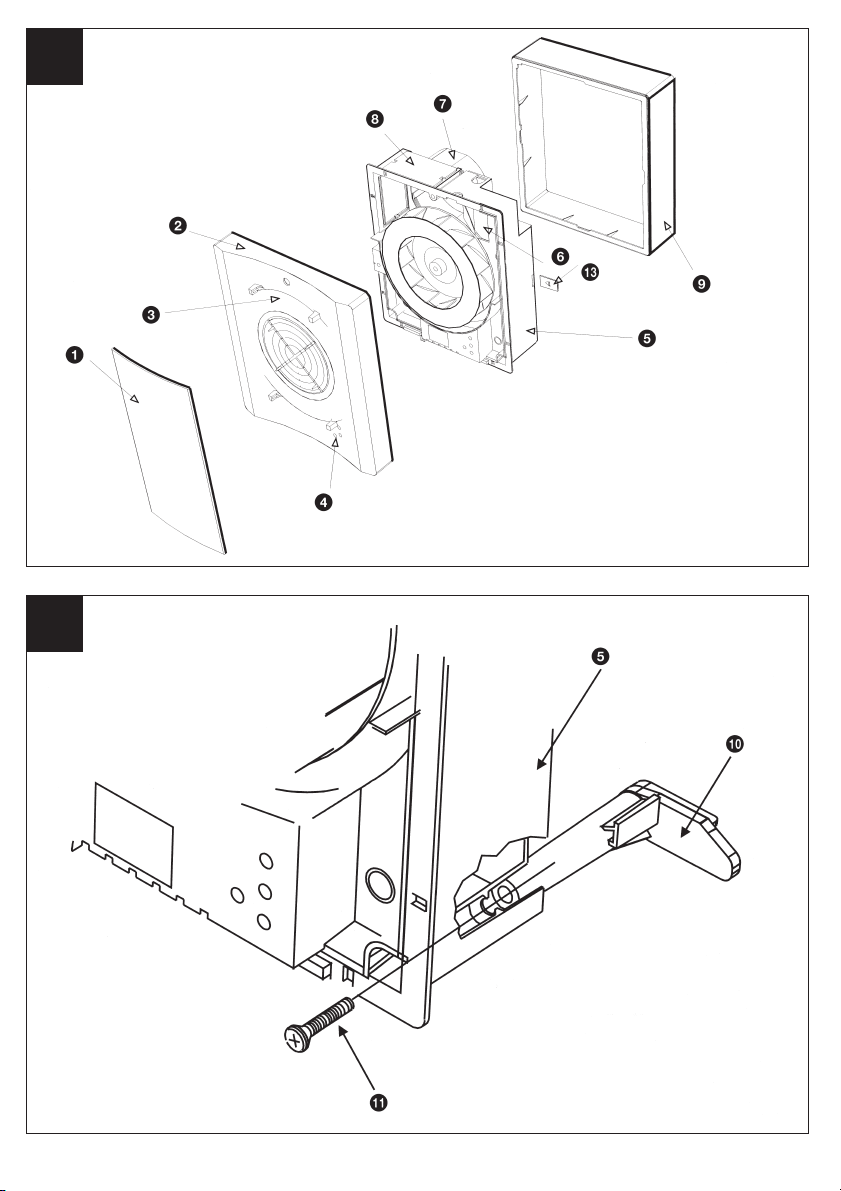

1 The surround 9is not required for this

installation.

2 Insert the fan box 5into the hole and

mark four positions using the slots in the

flange B.

3 Remove fan box 5from ceiling and fit

the four ceiling clips (supplied) over the

edge of the hole, so that the clips align

with the marks on the ceiling B.

4 Make a pilot hole 3.5mm diameter

through the hole of each clip. Ensure not

to damage the clip.

5 Fit the ducting to the circular spigot 7.

6 Offer the fan box 5up to the ceiling.

7 Pass the electrical cable into the fan box

5through the front cable inlet hole.

8 Using the screws !™, fix the fan box

flange to the ceiling clips.

1 Make good the outer hole if required.

Allow the mortar to set before continuing

the fan installation.

2 Fit the outer grille to the outer wall or for

ceiling mounting the appropriate

terminations.

♦If installing with a controller please refer

to Controller's Installation instructions.

♦Make sure the mains supply is isolated.

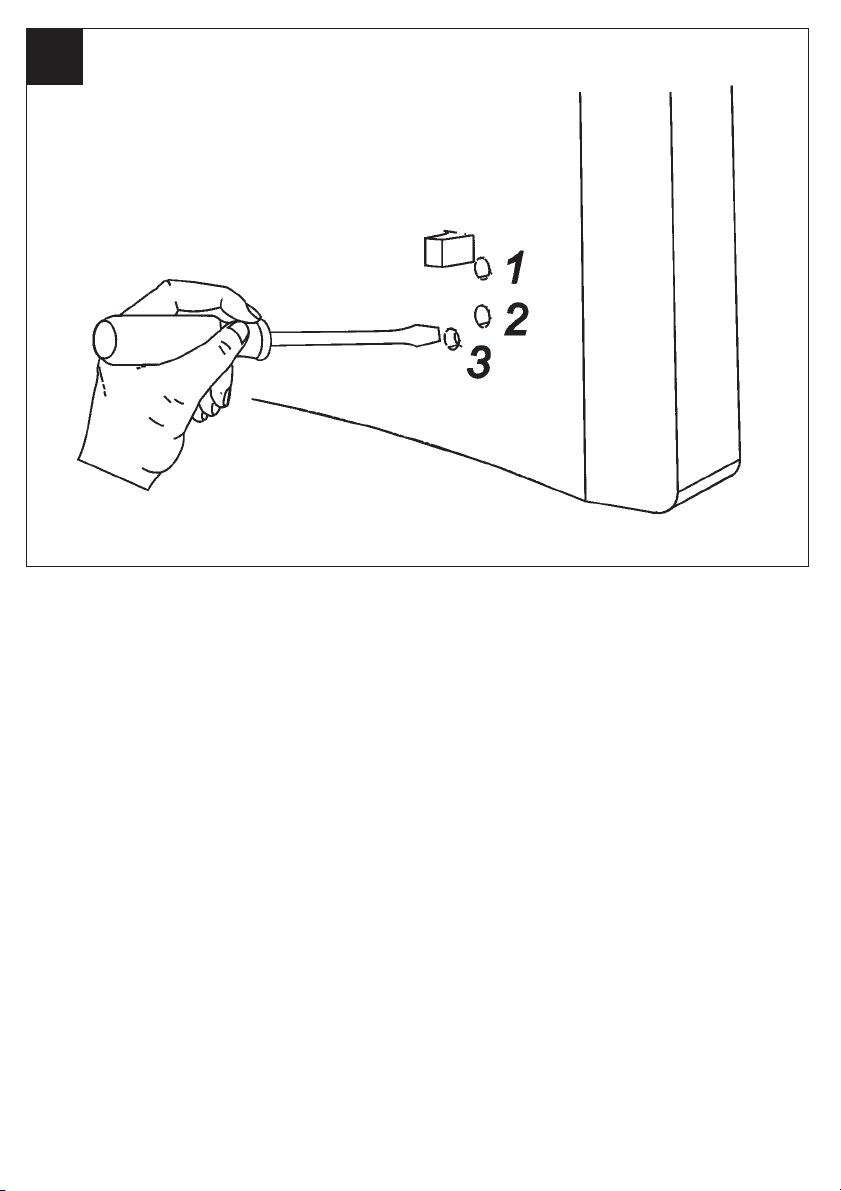

♦Before making electrical connections

pierce grommet with No. 2 pozi-drive

screwdriver.

DO NOT REMOVE GROMMET.

1 Remove the retaining screw of the

terminal cover 6and let the cover swing

out.

2 If wiring via cable clamp, remove the

cable clamp.

3a Wire the fan as shown in C. Check fan

model to diagram.

3b For dual speed operation, you will need a

COS (Change Over Speed Switch),

available from Xpelair.

3c For single speed operation at high speed,

connect the live supply to the LH

terminal.

3d For single speed operation at low speed,

connect the live supply to the LL

terminal.

4 If wiring via cable clamp, replace the

cable clamp and two screws. Ensure the

cable is firmly retained by the clamp.

5 Replace the terminal cover 6and fasten

the retaining screw.

6 Switch off the mains electrical supply

and remove fuses.

2 Mark on the wall or ceiling the positions

of the three fixing holes Din the fan box

5.

3 If wall mounting, drill three holes 5.5mm

diameter for wall plugs (supplied). If

ceiling mounting, use appropriate

fasteners.

4 Snap the surround support plates !£ to

the fan box 5.

5 Cut out the cable inlet hole in the

surround 9, if required. Slide the

surround 9over the fan box 5.

6 Pass the electrical cables into the fan box

5through the rear cable inlet hole.

7 Offer the fan box 5up to the wall or

ceiling making sure the circular spigot 7

enters the ducting.

8 Fix the fan box 5to the wall using

screws !¡ or to the ceiling using

appropriate fasteners (not supplied).

The surround 9is not required for this

installation. Fit the ducting to the circular

spigot 7.

If the hole size is as recommended:

1 Assemble the three fan body clamps !º

to the fan box 5using screws !¡.

2 Pass the electrical cables into the fan box

5through the front cable inlet hole.

3 Offer the fan box 5up to the wall

making sure the ducting enters the outer

wall. Ensure that the ducting slopes down

away from the fan to allow drainage of

any incoming water to the outside.

4 Tighten up the three screws !¡ until the

fan is clamped to the inner wall. The fan

body clamps !º will rotate to an

automatic stop position. Do not

overtighten.

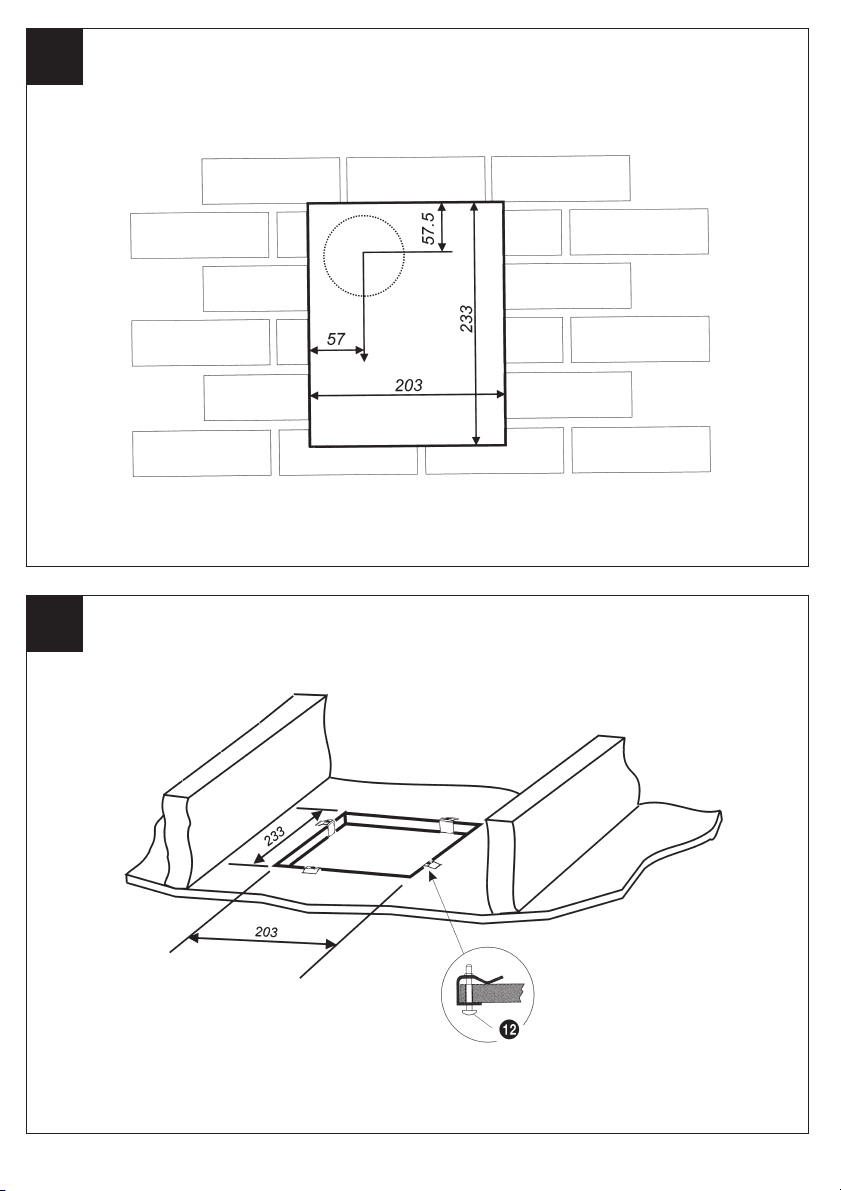

If the hole size is larger than

recommended i.e. larger than the flange

on the fan box 5.

1 The fan body clamps are not suitable.

2 Construct a wooden frame of internal

dimensions 203 x 233mm. Depth should

be at least 50mm.

3 Fit the wooden frame in the internal wall

and make good the hole.

4 Offer the fan box 5up to the wall

making sure the ducting enters the outer

wall. Ensure that the ducting slopes down

away from the fan to allow drainage of

any incoming water to the outside.

5 Allow the mortar to set before continuing

the fan installation.

6 Screw the fan box 5to the wooden

frame using the slots in the flange

(screws not supplied).

8

If installing in a wall

(flush mounting) Terminating the ducting

Wire the electrical connections

7 Connect the cable from the isolating

switch to the electrical supply wiring.

♦For fixed wiring circuits the protective

fuse for the appliance must not exceed

5A.

1 Refit front cover 2by placing the lower

lugs into the apertures on the fan box

flange and pivoting upwards over the

fan box 5. Fix with screw.

2 Fit spindle plugs 4onto the front cover

2.

3 Fit baffle plate 1onto the front cover 2

by locating the clips and carefully

snapping into position.

1 Before making any adjustments, isolate

the fan completely from the mains

supply.

2 Remove the baffle plate 1by unclipping

it using a sideways action.

3 Lever out the spindle plugs 4with an

electricians screwdriver.

4 Using an electrician's screwdriver, turn

clockwise to increase setting or anti-

clockwise to decrease setting.

DX200T

Timer over-run is approximately 2 minutes

minimum to 20 minutes maximum. Use

position 1G.

♦For single speed operation, the fan will

operate at the speed selected during

installation.

♦For dual speed operation, the fan will

operate at the speed selected on the COS

switch.

♦Operate the fan using the isolating

switch. Repeat to switch off.

(Light indicates when fan is switched on).

♦For single speed operation, the fan will

operate at the speed selected during

installation.

♦For dual speed operation, the fan will

operate at the speed selected on the COS

switch.

♦Operate the fan using the on/off switch.

When the switch is turned off, the fan

continues to operate for the adjustable

timer over-run period. (Light indicates

when fan is operating in manual mode).

Re-fitting fan covers

User adjustments

Using the fan

DX200

DX200T

If installing in a ceiling

(flush mounting)