2

BEFORE YOU START

The X10 is a high-quality, 1/10-pan car intended for persons aged 16 years and older with previous experience building and operating RC model racing cars. This

is not a toy; it is a precision car model. This model racing car is not intended for use by beginners, inexperienced customers, or by children without direct supervision

of a responsible, knowledgeable adult. If you do not fulfill these requirements, please return the kit in unused and unassembled form back to the shop where you

have purchased it. Before building and operating your X10, YOU MUST read through all of the operating instructions and instruction manual and fully understand

them to get the maximum enjoyment and prevent unnecessary damage. Read carefully and fully understand the instructions before beginning assembly. Make sure

you review this entire manual and examine all details carefully. If for some reason you decide the X10 is not what you wanted or expected, do not continue any

further. Your hobby dealer cannot accept your X10 kit for return or exchange after it has been partially or fully assembled.

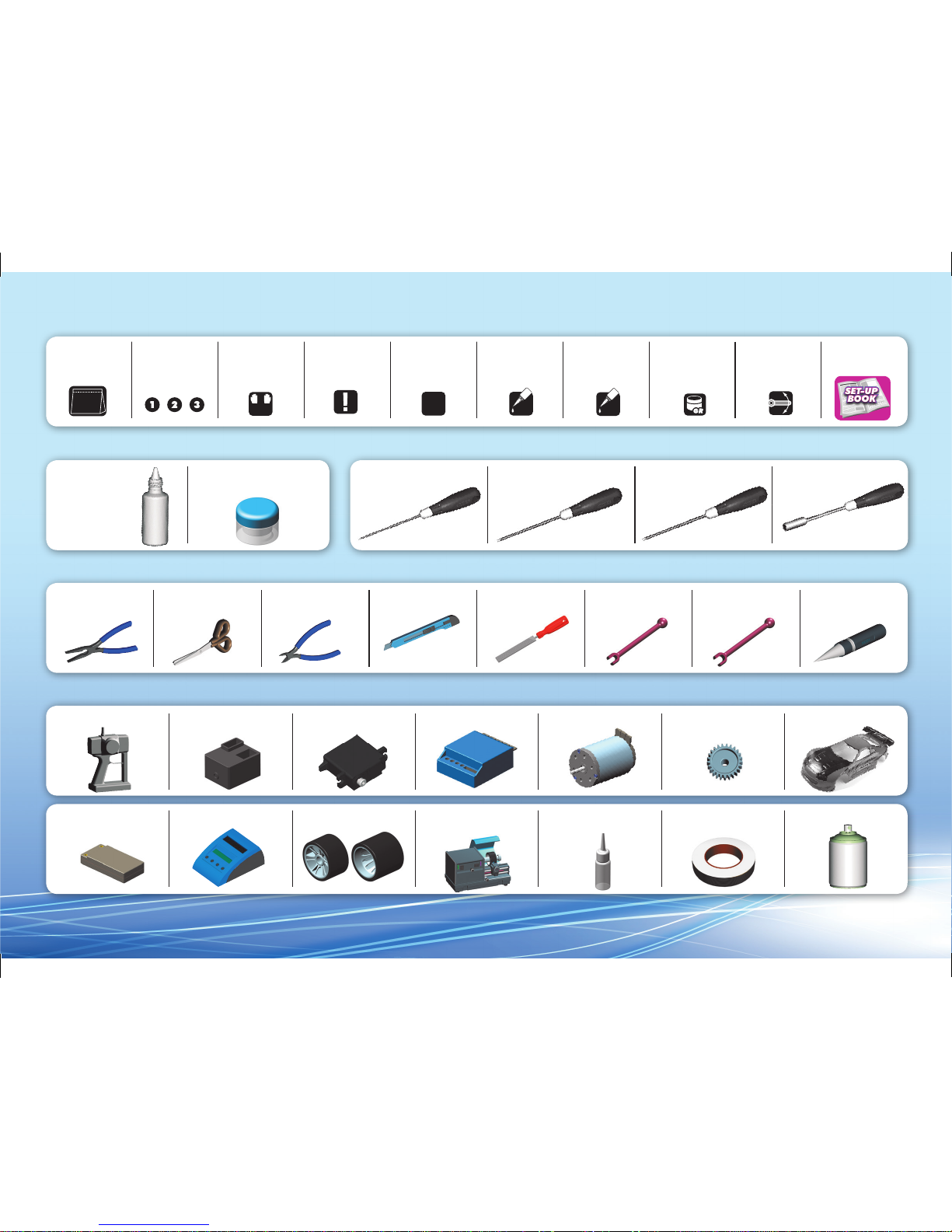

Contents of the box may differ from pictures. In line with our policy of continuous product development, the exact specifications of the kit may vary without prior

notice.

Failure to follow these instructions will be considered as abuse and/or neglect.

In line with our policy of continuous product development, the exact specifications of the kit may vary. In the unlikely event of any problems with your new kit, you

should contact the model shop where you purchased it, quoting the part number. We do reserve all rights to change any specification without prior notice. All rights

reserved.

CUSTOMER SUPPORT

We have made every effort to make these instructions as easy to understand as possible. However, if you have any difficulties, problems, or questions, please do not

hesitate to contact the XRAY support team at info@teamxray.com. Also, please visit our Web site at www.teamxray.com to find the latest updates, set-up information,

option parts, and many other goodies. We pride ourselves on taking excellent care of our customers.

You can join thousands of XRAY fans and enthusiasts in our online community at: www.teamxray.com

XRAY USA

RC AMERICA, 2970 BLYSTONE LANE

SUITE 109, DALLAS, 75220 TEXAS

USA

PHONE: 214-744-2400

FAX: 214-744-2401

XRAY EUROPE

K VÝSTAVISKU 6992 , 91101 TRENČÍN

SLOVAKIA

EUROPE

PHONE: 421-32-74401100

FAX: 421-32-74401109

E-MAIL: info@teamxray.com