1

Focusing on Laser Imaging and Decorating xTool D1 Laser Engraver/Cutter

FIG. 1. e xTool D1, available as either a 5W or 10W version,

is the company’s first entry in the diode laser market. Credit: xTool

Construction. e D1’s solid aluminum alloy construction is

noteworthy since the xTool opted for the strongest materials,

yielding a laser head that glides smoothly on stainless steel wheels

along a wear-resistant guide rail structure, producing very im-

pressive laser spot accuracy and consistency, with a minimum

of vibration. e X and Y axis movement is controlled with

two stepper motors, contained within the frame, advancing the

pre-installed belts that deliver the laser head to its required co-

ordinates. With the stepper motors, belts, and electronics con-

cealed and protected within the frame, the overall look of the

D1 is exceptionally clean, sleek, and high-tech.

Assembly. e assembly process can take as little as 15 minutes

for an experienced assembler, or 30 to 45 minutes for a beginner.

e fit-and-finish of the parts is exceptional. Several of the com-

ponents, such as the belts, stepper motors, and motherboard

have been pre-assembled, not only reducing assembly time, but

ensuring that precision parts have been factory set.

Focus. Since focus is a critical element in producing usable out-

put, the D1 is notable since it offers a best-in-class solution.

A finger screw on the left side of the laser head loosens it so

that it can be moved up and down, closer or further from the

workpiece, along the Z-axis. e amount of upward movement

is significant, since it determines how high or thick the materi-

al that can be processed. A focus device, called the ranging rod

(FIG. 2), is built into the right side of the laser head and is held

in place magnetically. e user flips the rod down, adjusting the

laser head until the rod touches the workpiece. e laser is now

in focus, the set screw is tightened, and rod is returned to its

upright position. e built-in rod is not only convenient, but it

is always immediately accessible.

e maximum speed of the laser head is 10000mm/min. which

is considered exceptionally high.

e rated electric power of the laser head is 40W, outputting a

laser power of 10W. Rather than sell the device as a 40W laser,

xTool only touts its true laser strength of 10W. is honest as-

sessment of the true laser rating is, unfortunately, a rarity in the

industry.

e laser head is a bit of an engineering marvel, given that it

contains two 5W laser emitters; one directed straight down, and

a second directed at a 45 degree mirror (FIG. 3). ey are cooled

by a built-in fan, that despite its strength, is relatively quiet. e

dual lasers produce a very small, square laser spot of 0.08mm

x 0.08mm which produces high-resolution images, and clean,

FIG. 2. e ranging rod, shown here in mid-position, offers the eas-

iest solution to setting accurate focus quickly and consistently.

e xTool D1 10W Laser Engraver/Cutter

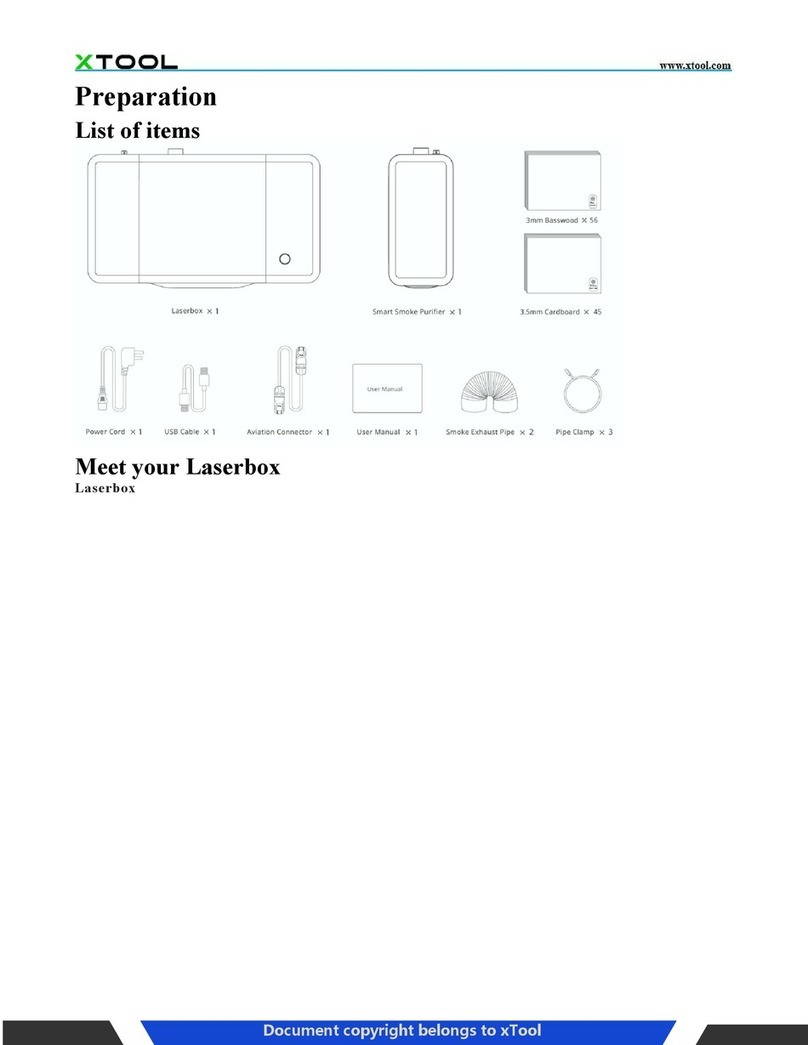

e xTool D1 10W (FIG. 1) has been engineered by industrial designers who have produced high-end CO2

laser engraver/cutters, and who have applied their design and manufacturing know-how to enter the diode la-

ser market. e xTool D1 is the result of their mission to enter the hobbyist market with a machine that excels

in significant ways, including a motion accuracy precision of up to 0.01mm.

e parent company of xTool is Makeblock, a world-renowned company in the STEAM education space,

founded in 2013. It is a leading provider of technologies for education, with more than 100 worldwide dis-

tributor partners. xTool was launched in 2019 with its first product, the xTool Laserbox CO2 laser engraver/

cutter.

©2022, Michael Kleper, Boynton Beach, FL. All rights reserved. is entry is an excerpt from

Focusing on Laser Engraving and Decorating: Affordable, Versatile, and Creative Marking, Engraving and Cutting,

publication summer, 2022 on Amazon.