CONTENT

OPERATION INSTRUCTIONS ............................................................................................................................ I

MAINTENANCE TIPS.......................................................................................................................................... I

AFTERSALES-SERVICES .................................................................................................................................. I

CONTENT ............................................................................................................................................................ I

1. GENERAL INTRODUCTION..................................................................................................................... 3

Main Units........................................................................................................................................................................3

Device Specifications.......................................................................................................................................................5

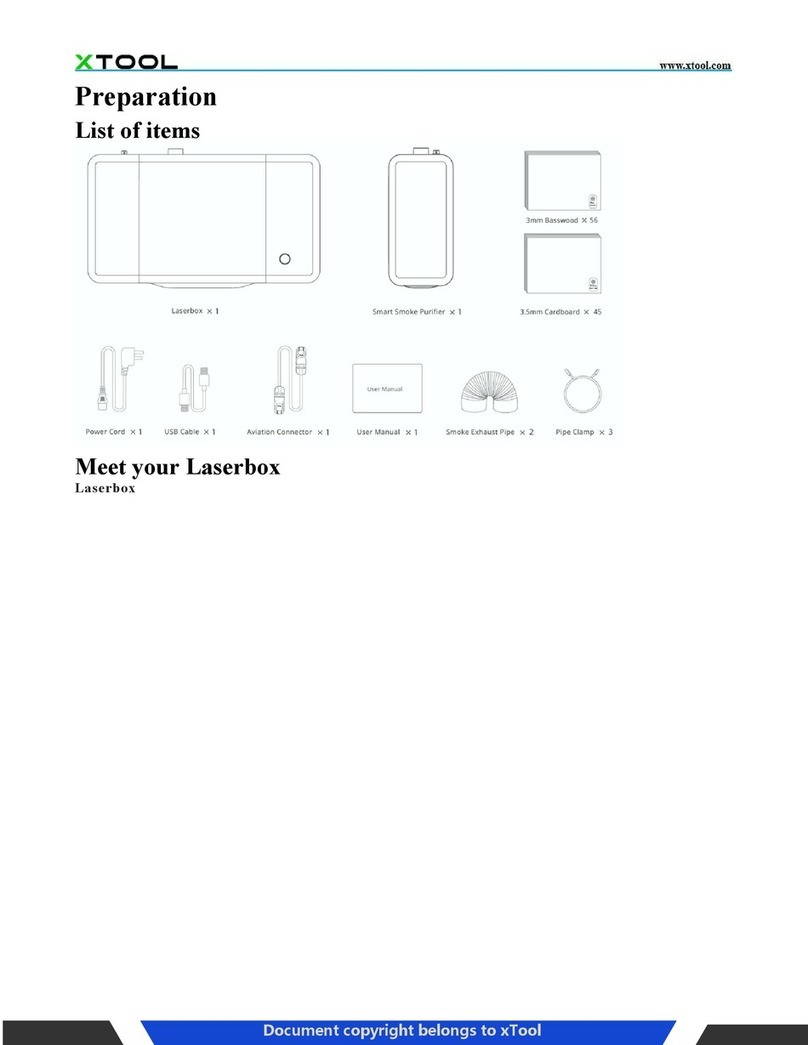

Packing List .....................................................................................................................................................................5

2. GETTING STARTED................................................................................................................................. 5

Remove Protection Frame...............................................................................................................................................5

Install Probe & Cutter.......................................................................................................................................................6

Install Jaw........................................................................................................................................................................6

Battery Charging..............................................................................................................................................................7

ON/OFF Switch................................................................................................................................................................7

Machine Calibration.........................................................................................................................................................7

3. OPERATIONS ........................................................................................................................................... 8

Cut Keys By Codes..........................................................................................................................................................8

Select BY Manufacturer...................................................................................................................................................9

Select BY Key Profile.....................................................................................................................................................10

Select Chinese Key Profiles...........................................................................................................................................10

Special Keys..................................................................................................................................................................10

Key Cutting Menu ..........................................................................................................................................................11

Key Cutting For Special Keys........................................................................................................................................ 13

Cutting keys with multiple sides.....................................................................................................................................13

Tips on Cutting Keys......................................................................................................................................................17

All Keys Lost Search......................................................................................................................................................18