i144812(D)

Table of Contents

CHAPTER 1 – INTRODUCTION ...................................................................................................................................1

PRODUCT OVERVIEW ....................................................................................................................................................1

Standard Features .................................................................................................................................................1

Optional Features...................................................................................................................................................1

Unpacking the Unit.................................................................................................................................................2

QUICK STARTUP ...........................................................................................................................................................2

CHAPTER 2 – INSTALLATION.....................................................................................................................................3

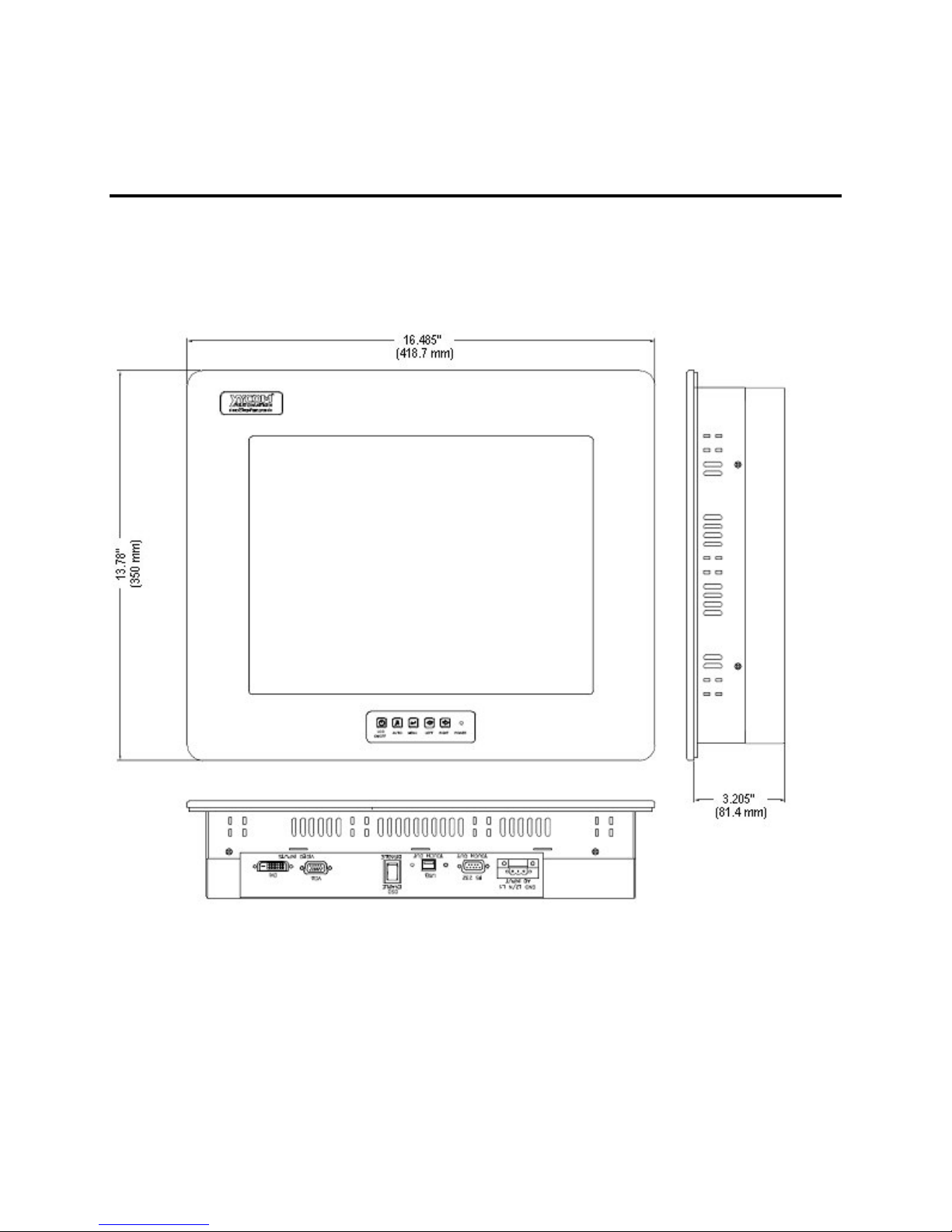

PRODUCT DIMENSIONS ..................................................................................................................................................3

5015SLR Dimensions (Black Bezel) ......................................................................................................................3

5015SLR Dimensions (Stainless Steel Bezel) .......................................................................................................4

Front Panel Controls ..............................................................................................................................................5

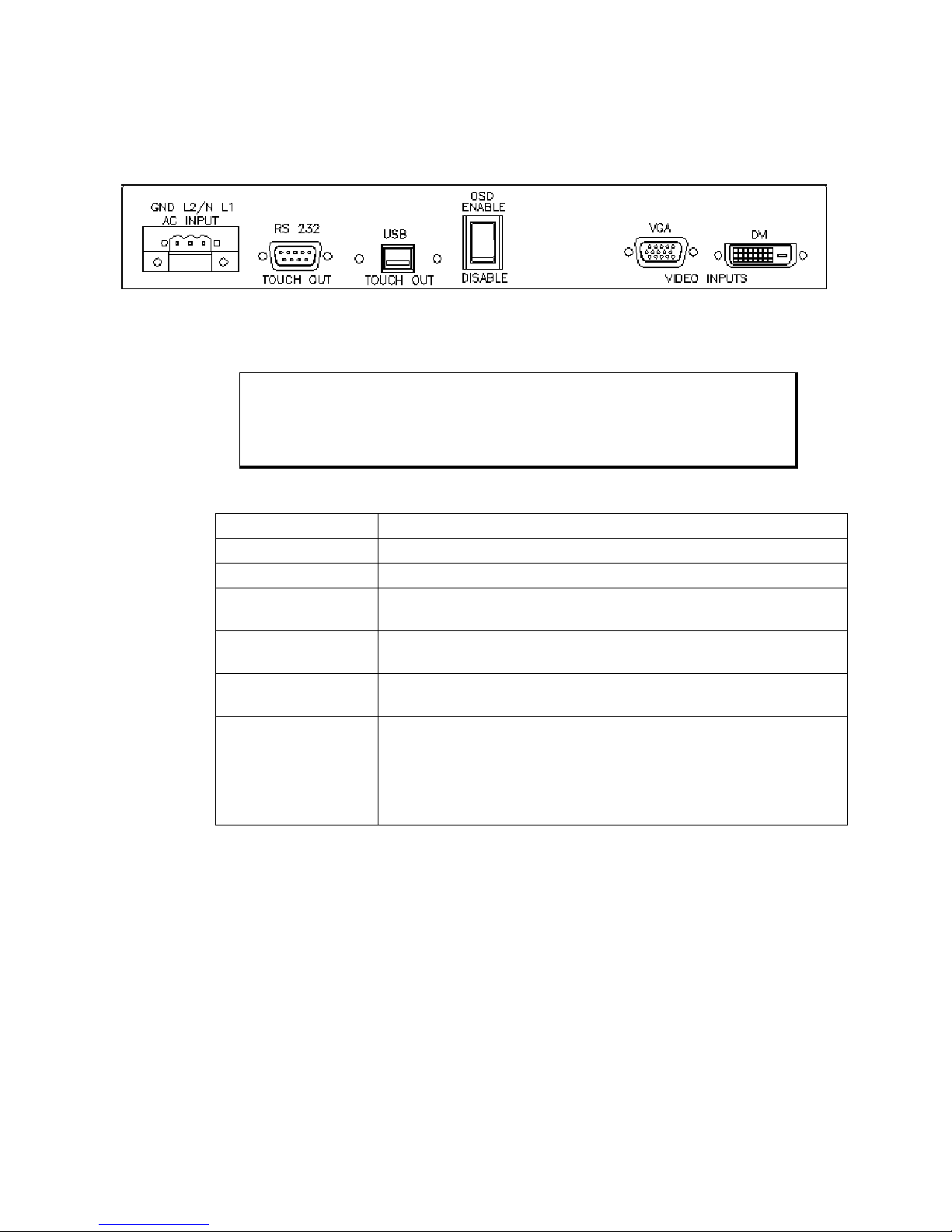

Rear Panel Controls...............................................................................................................................................5

I/O Panel ................................................................................................................................................................6

LOCATION AND ENCLOSURE CONSIDERATIONS .................................................................................................................7

PANEL INSTALLATION.....................................................................................................................................................8

POWER MANAGEMENT.................................................................................................................................................11

System Power......................................................................................................................................................11

Excessive Heat ....................................................................................................................................................13

Electrical Noise ....................................................................................................................................................13

Line Voltage Variation ..........................................................................................................................................14

HAZARDOUS LOCATIONS INSTALLATIONS .......................................................................................................................14

Definitions ............................................................................................................................................................16

Power Switch .......................................................................................................................................................18

Cable Connections...............................................................................................................................................18

Operation and Maintenance.................................................................................................................................19

Safety Agency Approval.......................................................................................................................................19

CHAPTER 3 – MONITOR SETTINGS .........................................................................................................................20

ON-SCREEN DISPLAY (OSD) SWITCH ..........................................................................................................................20

MODE AND IMAGE ADJUSTMENT ...................................................................................................................................20

Recall the Factory Default Settings......................................................................................................................23

ANALOG RGB INTERFACE SPECIFICATIONS ...................................................................................................................23

VIDEO MODES ............................................................................................................................................................24

CHAPTER 4 – OPERATOR INPUT.............................................................................................................................25

INSTALLING THE TOUCH SCREEN DRIVER ......................................................................................................................25

CALIBRATING THE TOUCH SCREEN................................................................................................................................26

ACCESSING THE “MOUSE RIGHT BUTTON” FUNCTIONALITY WITH THE TOUCH SCREEN .......................................................26

USING A POINTING DEVICE WITH A TOUCH SCREEN FOR DOS .........................................................................................26

CHAPTER 5 – HARDWARE........................................................................................................................................27

VGA INPUT CONNECTOR.............................................................................................................................................27

DVI-D INPUT CONNECTOR ..........................................................................................................................................28

SERIAL INTERFACE ......................................................................................................................................................28

Touch Screen RS-232 Output Connector ............................................................................................................29

TOUCH SCREEN USB OUTPUT CONNECTOR .................................................................................................................29

HARDWARE SPECIFICATIONS........................................................................................................................................30

ENVIRONMENTAL SPECIFICATIONS ................................................................................................................................31

BEFORE CONTACTING TECHNICAL SUPPORT..................................................................................................................32

CONTACTING TECHNICAL SUPPORT ..............................................................................................................................32

PRODUCT REPAIR PROGRAM / RETURNING A UNIT TO PRO-FACE.....................................................................................33