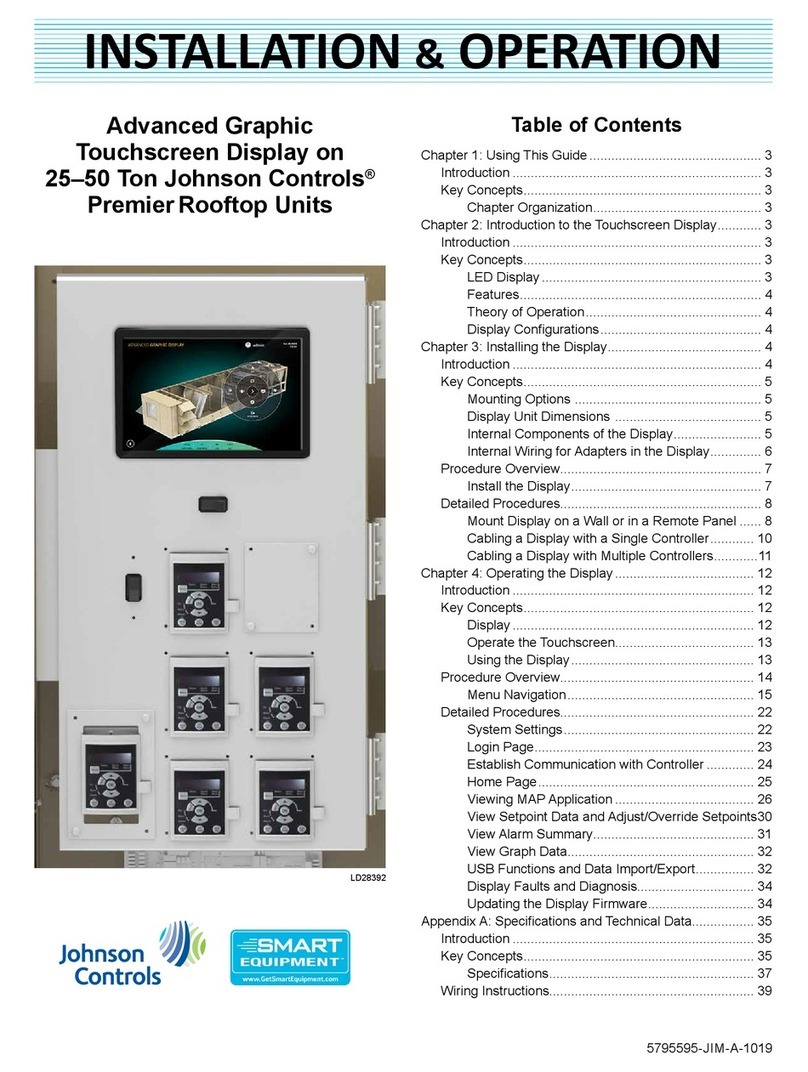

Contents

ContentsIntroduction.....................................................................5

Key concepts..............................................................5

Chapter organization..........................................5

Introduction to the touchscreen display......................6

Key concepts..............................................................6

LED display...........................................................6

Features................................................................6

Theory of operation............................................ 7

Display configurations........................................7

Related information............................................ 7

Installing the display...................................................... 8

Key concepts..............................................................8

Mounting options................................................8

Display unit dimensions..................................... 8

Internal components of the display..................8

Internal wiring for adapters in the

display...................................................................9

Procedure overview................................................ 11

Install the display.............................................. 11

Detailed procedures............................................... 12

Mount display on a wall or in a remote

panel................................................................... 12

Cabling a display with a single controller...... 14

Cabling a display with multiple

controllers.......................................................... 15

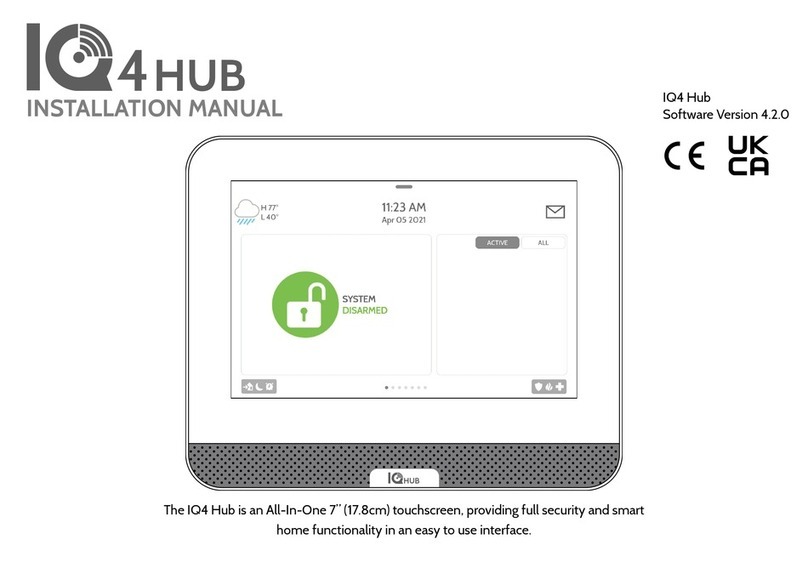

Operating the display...................................................17

Introduction.............................................................17

Key concepts............................................................17

Display................................................................ 17

Operate the touchscreen................................. 17

Using the display...............................................17

Procedure overview................................................ 18

Detailed procedures............................................... 19

System settings................................................. 19

Login page......................................................... 20

Establish communication with controller.......22

Home page.........................................................23

Setting up and viewing MAP application........25

Menu navigation............................................... 30

View setpoint data and adjust or

override setpoints............................................. 40

View alarm summary........................................41

View graph data................................................ 42

USB functions and data import and

export................................................................. 42

Display faults and diagnosis............................ 43

Updating the display firmware........................44

Appendix A: Specifications and technical data..........45

Introduction.............................................................45

Key concepts............................................................45

Specifications.....................................................46

Wiring instructions..................................................48

Johnson Controls

Advanced Graphic Touchscreen Display on 25 Ton to 80 Ton Johnson Controls Premier Rooftop Units 3